Ground-scanning

Beamway for Energy Crops

by

Olav Naess

Harvesting Solar

Energy

Solar cells are fine for

collecting solar energy, but become expensive and obtrusive for large

scale energy harvesting.

Harvesting the energy

through plants, from which liquid fuel is produced, is likely to be

preferrable for large scale operation. Covering large areas with

solar cells will block and disturb human and animal activities,

unless the solar cell array can be placed in a desert, whereas an

energy crop area can be quite usable for people and animals if it is

designed following the guidelines outlined below. The natural energy

carrier from energy crops will be liquid fuel, which is the most

convenient energy carrier for vehicles.

Hydrogen is commonly

regarded as the energy source of the future: clean and CO2-neutral.

But hydrogen (for chemical combustion) is not an energy source, just

an energy carrier – like a copper cable is. And it is difficult

to store and transport, requiring either high pressure, supercooling,

or chemical binding which yields an awkward to handle solid, or at

best a liquid 3-4 times less energy efficient than gasoline or

diesel. Descriptions of chemical hydrogen binders generally disregard

the most efficient binder: carbon – evidently because the

carbon-hydrogen combinations are simply the old familiar fuels:

gasoline, diesel and (with a little oxygen added) alcohol. But when

the carbon is borrowed from the air, energy crop products like

biodiesel become CO2-neutral, consequently becoming valid

and efficient hydrogen economy products. A purism denouncing these

fuels will be just a stunt environmentalism.

It is now (in 2008)

common to reject fuel crop growing (like the bio-ethanol production

in Brazil, or the corn-based fuel production in the US) due to

present production methods consuming significant amounts of farmland,

farmer workpower, fertilizers and even production machinery fuel.

The purpose of this

article is to outline a production method which:

uses less energy –

because rail transport is far more energy efficient

needs no farm land

– because quite awkward terrain can be used

requires very

little farmer workpower – because computer controlled

machinery will do most of the work

can do without

fertilizers – because all harvested crops (minus the energy

and what the atmosphere later re-supplies) are brought back to the

fields

The energy crop plants

needn't be limited to the few species which presently seem to have

been chosen by farmer habits. Harvesting several meters above the

ground could for instance mean that the plants can be combination

plants: A bush or tree on the ground (the host plant) can have an

undisturbed root and leaf canopy, and other plants grafted on top of

it should just shoot energy rich stems upwards. The upper plant could

repeatedly be harvested by being cut a little above the grafting

point. It might be genetically modified to yield maximum energy

content, and might be unable to grow a root and procreate. Vegetable

oils are fuels which are simple to extract and use. The plants

yielding most of these oils are listed

here. Genes from one of the best of these plants might be

transferred to graftable plants in which the young stem could be

oil-producing. Gene manipulation is controversial when done in food,

but shouldn't be so problematic for energy crops, particularly if the

artificial plants lack a root.

If mangroves could be

used as host plants, biofuel could be produced in wetlands.

The object of the

following technique is: To enable energy-efficient and

computer-controlled access for machinery and crop containers to all

parts of the field to be cultivated, even if the terrain is quite

uneven.

Ground-scanning

with Beamway

Working

the earth by means of machines essentially implies XY-scanning the

two-dimensional surface like a computer printer/plotter does with a

sheet of paper. This work is traditionally done by moving the

machinery across an earth surface which, for the sake of work

efficiency, is quite flat, although the plants don't need this

flatness. In the contrary: A slope facing the sun would receive more

energy.

Transporting

passengers and goods is much more energy efficient on rail than on

roads, and the worst road is less energy wasting than the most level

soil. So why not do agriculture by means of an XY-scanning railway

which is elevated over that messy earth surface? The beamway,

as described in other articles on this website, is quite suitable for

this purpose.

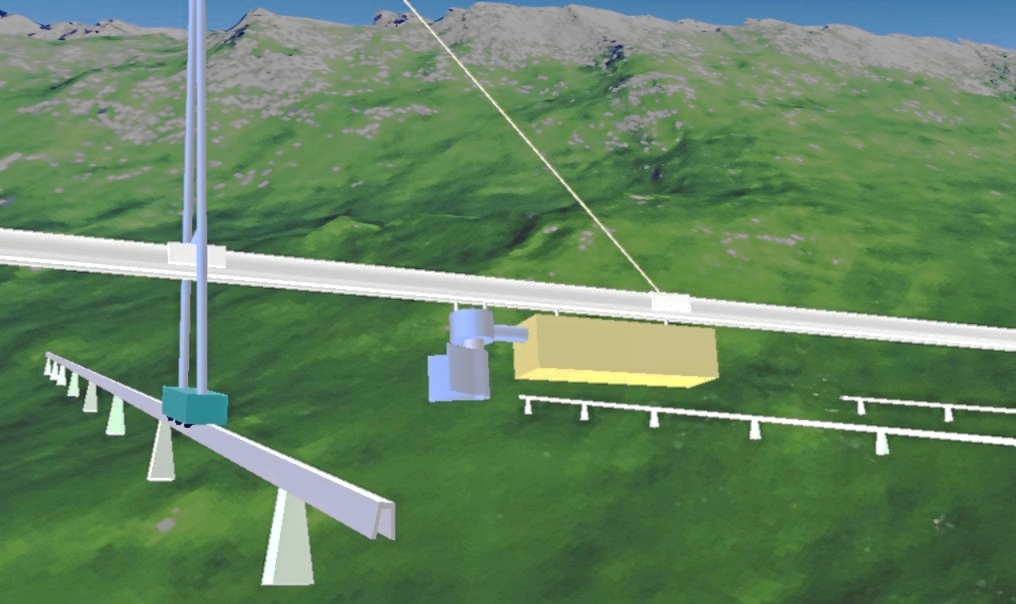

This

energy crop field on a sunny slope is harvested automatically by

XY-scanning railways. The two towers rolling upon the lower rails

hold the upper rail, a beamway as described in the beamway

introduction article. The machinery for harvesting (and otherwise

working) the fields are moving around computer-controlled like

beamway trains, along with connected crop container wagons. This

machinery should to some extent be able to move vertically, so that

it can deal with uneven terrain, and may then be compared with an XYZ

plotter.

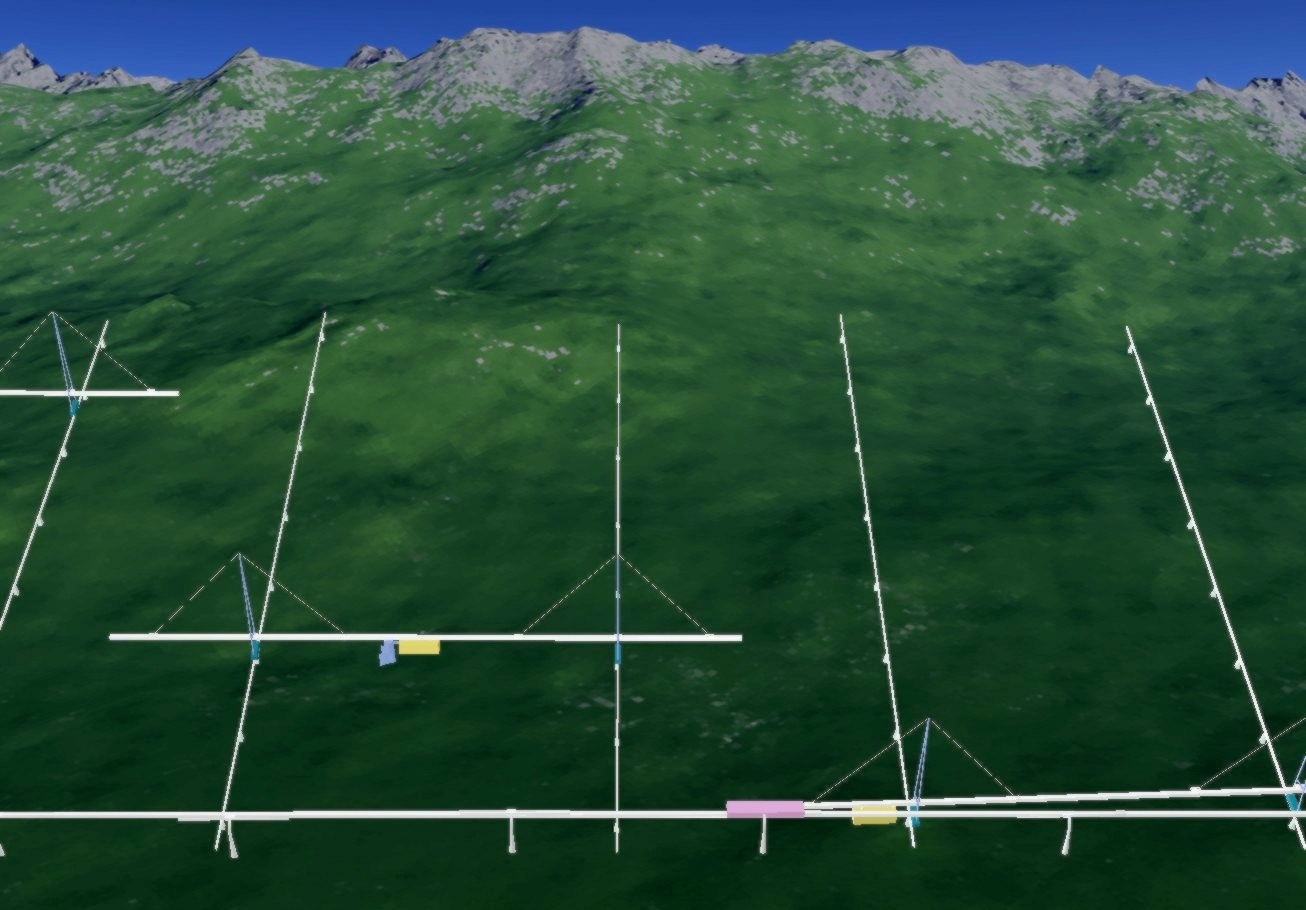

This

energy crop field on a sunny slope is harvested automatically by

XY-scanning railways. The two towers rolling upon the lower rails

hold the upper rail, a beamway as described in the beamway

introduction article. The machinery for harvesting (and otherwise

working) the fields are moving around computer-controlled like

beamway trains, along with connected crop container wagons. This

machinery should to some extent be able to move vertically, so that

it can deal with uneven terrain, and may then be compared with an XYZ

plotter.

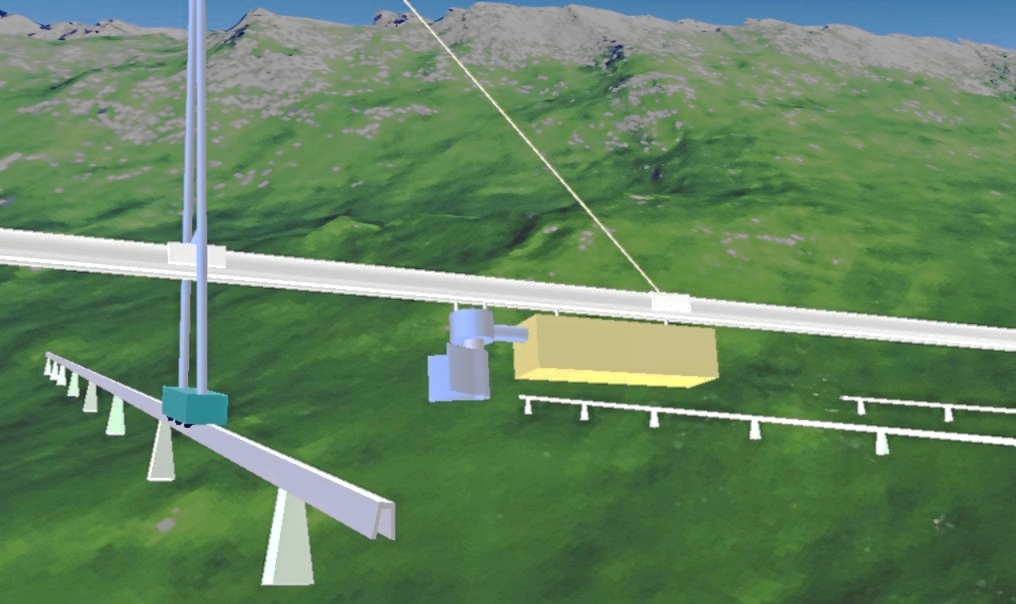

The

movable beam to the right has connected its left end to a switch

(which serves also the other adjacent rectangle), so that the

container on that beam can enter the external beamway running along

the lower part of the picture.

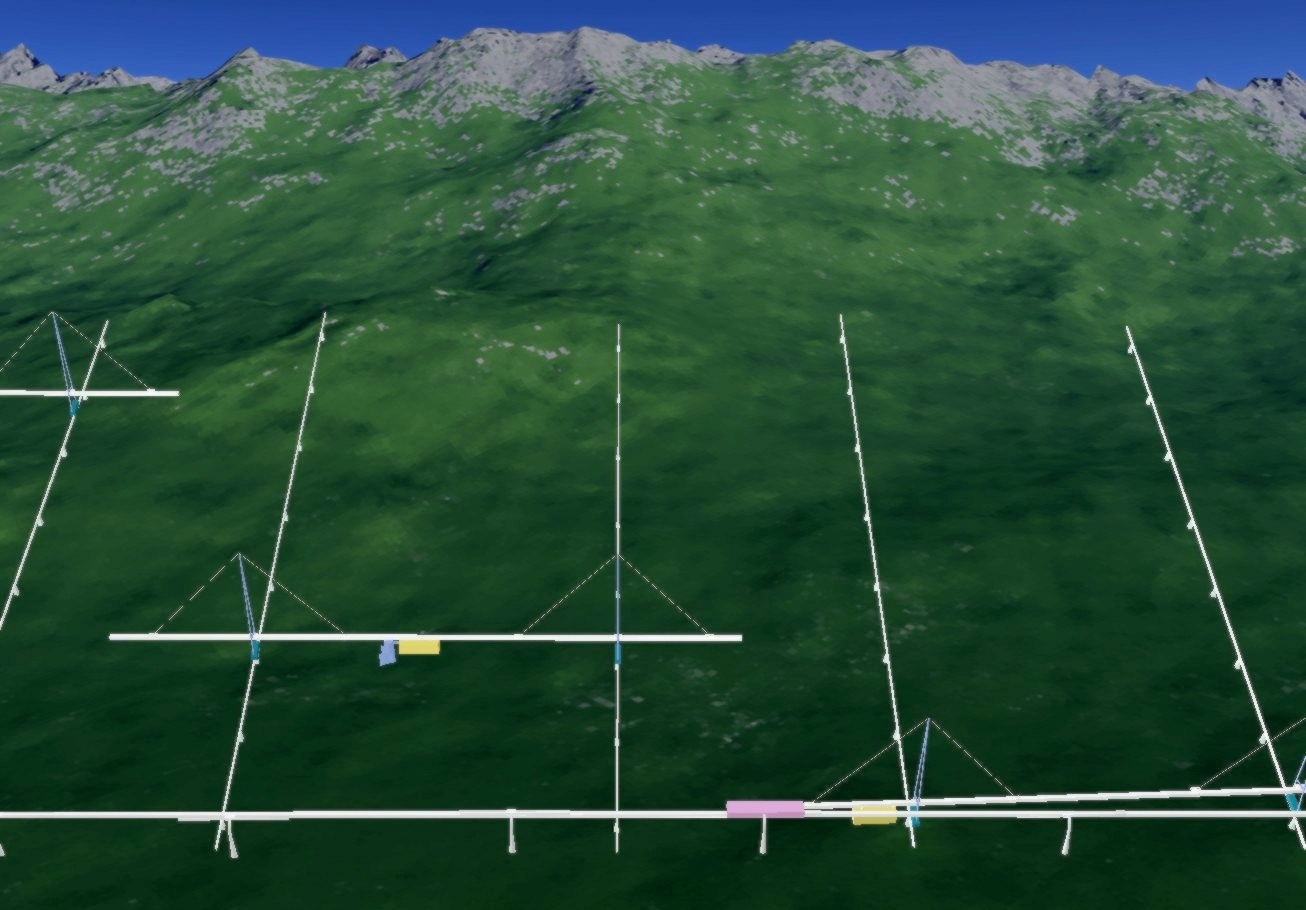

The

lower rails can have unlimited lengths, or they can, like in this

picture, go up a hillside, so that the movable upper rails, along

which there is more movement, can be more level. The lower rails are

held up by concrete pillars, 2-3 meters above the ground, so that

people and animals can pass freely across the fields.

In

wetlands, the lower rails may be omitted, and the upper rail can be

carried by floaters guided by cables running where the lower rail

would have been.

The

lower rails may seem to be monorails, but it would be more correct to

regard a pair of them as constituting a very wide-gauged standard

track, as the two bogies are connected (by a crossing, upper rail) to

act like one. When this wide bogie connects with the external

beamway, it should be skewed, so that only one end of the moving beam

contacts with the external beam. If there is little traffic on the

external beam, so that switching speeds are unimportant, a simplified

switching mechanism may be used: The end of the moving beam can push

aside the adjacent end of the external beamway beam in order to take

its line connection. The skewed position of the moving beam may be

permanent.

An

alternative method for connecting to the external beamway is: All the

movable beams are lined up with each other and with the end of the

external beamway.

The

harvester is ready, but the tall energy plants are not sown yet.

Working

from a beamway across the fields has several advantages:

The

field may be sloped, uneven, marshy, or simply a water surface.

Energy crops growing in water (e.g. like rice on terraces)

need not close their respiration pores to conserve water, so they

can avoid wasting their energy on breathing (destroying their

carbohydrate fuel) during nights.

Energy

plants need not be cut at the ground (coppicing),

but can be cut well above the ground (pollarding).

This

means various animals can live rather undisturbed on the ground,

and/or people can use the area as a park, walking on paths which

don't reduce the harvesting area. The leaves in a permanent canopy

enable the plants to rapidly grow the leafless new stems which are

ideal for energy harvesting.

Traffic

on elevated rails is simple to automatize, and doesn't conflict so

much with animal life.

If the machines work at night, it is

easier for their IR-detectors to detect the presence of body heat.

(And people using the area as a park are not much disturbed.)

If

there is a need for working the earth (plowing, tilling, root

removal, etc.) the beamway can't exert so much force as a tractor on

the ground, but it can use weaker tools and compensate by working

rapidly day and night. Also harvesting should be done steadily at a

low noise level, thus requiring small and simple machinery.

Crop

containers on the beamway can easily be sent to an industrial area

(with e.g. a power plant), moved by motorized bogies. They may spend

some time in front of parabolic mirrors – for sun energy

treatment like removing excess moisture.

The

masses remaining when the energy/fuel has been extracted, are likely

to be exactly what the plants need as fertilizer, so they are sent

back and spread on the field. A conventional ground-based harvesting

method is unlikely to do this properly and economically.

Energy

crops are likely to be in danger of crop field fires, but the

ground-scanning beamway system has unique potentials for firefighting

because its vehicles are always ready to go anywhere unmanned. One of

the extreme positions for the movable beam should be over a safe area

devoid of inflammable materials. This could be a road or a river, and

if there is a connection to an external beamway line, it should be in

this safe area. It should be possible for machines to suck up water

there and store it in standard crop containers. Then the beamway

vehicle could go for the flames like an over-sized ink-jet printer,

guided by IR-detectors in the top of one of its towers.

The

external beamway line is hopefully a useful line for other goods and

passenger transport purposes, so a large biomass processing system,

with extensive crop fields served by a large processing factory (or

power plant), should be quite economical.

3D

Landscape Printing

This

XYZ mechanism can also be used for shaping the landscape – just

like those 3D printers presently used for creating small objects.

But this beamway-based mechanism can be used on a much larger scale –

for building groups of houses. With "ink jets" for

concrete, sand, isolating foam and plastic materials, it can build

platforms, plumbing and walls, and then transport in beams and floor

plates to place upon the walls. The vegetation layout is of course

created by the same mechanism, also in gardens, verandas and on

roofs.

Copyleft

Olav Næss

2006, 2008

Olav Næss

2006, 2008

This

energy crop field on a sunny slope is harvested automatically by

XY-scanning railways. The two towers rolling upon the lower rails

hold the upper rail, a beamway as described in the beamway

introduction article. The machinery for harvesting (and otherwise

working) the fields are moving around computer-controlled like

beamway trains, along with connected crop container wagons. This

machinery should to some extent be able to move vertically, so that

it can deal with uneven terrain, and may then be compared with an XYZ

plotter.

This

energy crop field on a sunny slope is harvested automatically by

XY-scanning railways. The two towers rolling upon the lower rails

hold the upper rail, a beamway as described in the beamway

introduction article. The machinery for harvesting (and otherwise

working) the fields are moving around computer-controlled like

beamway trains, along with connected crop container wagons. This

machinery should to some extent be able to move vertically, so that

it can deal with uneven terrain, and may then be compared with an XYZ

plotter.