The

Beamway

by Olav Naess,

2006-2014

A

City Beamway

Metros

and Architecture

Scalability

The

Safety

Cargo

Additional

Passenger Wagons

Private

Pods

Mobile

Services

Running

(between) Hospitals

Post

Commuters

The

Disabled

The

Environment

Existing

Beamways in Germany

The

Main Points

Summary

This is about the

question: Perhaps there should be railways for transporting people?

For transporting

passengers (with 6-8 tons/wagon), it is a very bad idea to use

conventional heavy rail (for over 100 tons/wagon).

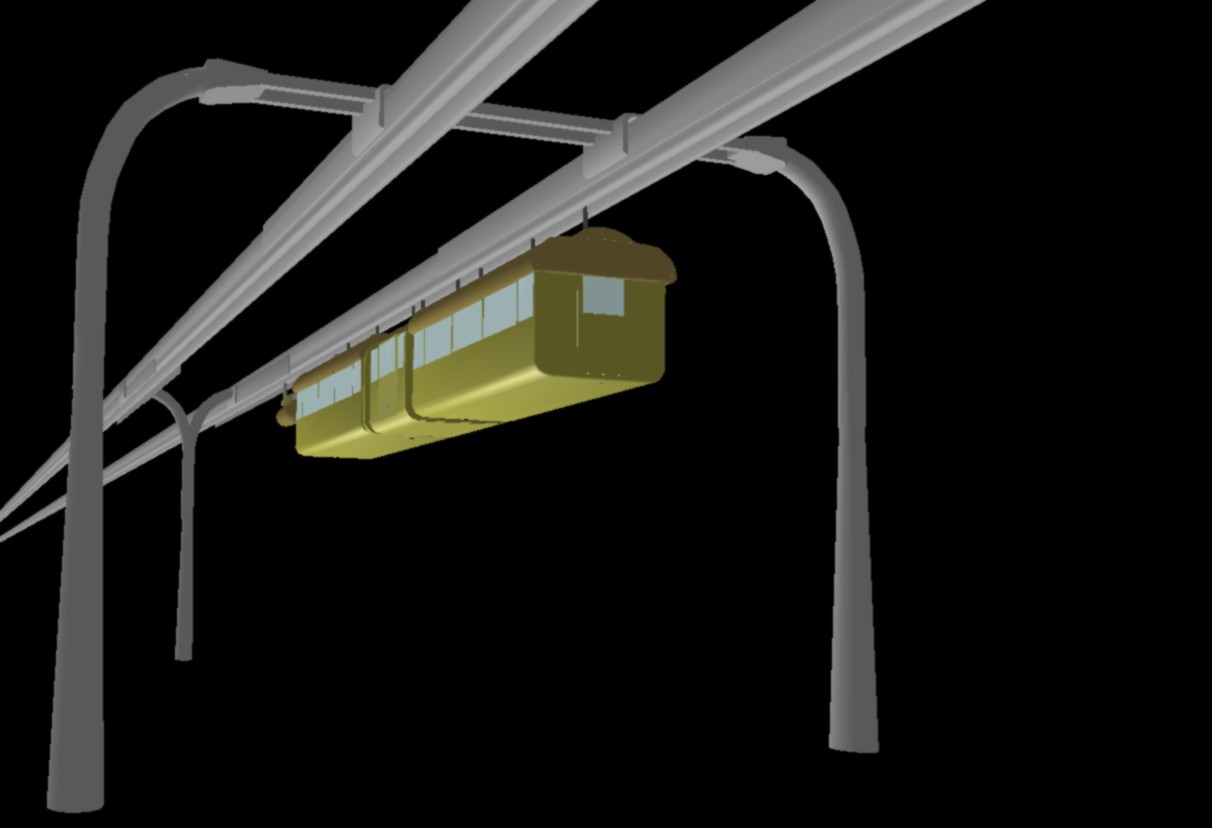

A (correctly

weight-adapted) beamway should then be used. This is a suspended

monorail running along a steel beam. These trains can run above other

ground activities (road traffic, pedestrians, playing children,

wildlife, avalanches, untouched nature...). The beamway can negotiate

slopes of over 10%, and give a 99% reduction of ground razing,

barrier formation and snow problems.

This

is important for the environment.

Additional track

area will not be needed in difficult/congested areas, as the beamway

goes above roads – also across road bridges. If the beamway

tunnels run along road tunnels, free escape tunnels are obtained.

As

the beamway grips cabins at the upper edge, it can easily transfer

cabins (4-24 meters long) between ground positions, boat decks...

Such

cabins can be used for recreational/living

quarters, mobile services...

The

beamway can also move cars, boats,

cargo containers...

Suspended

monorails are now in operation in

e.g. Germany, but should be improved (for 200 km/h) as described

in this article, and with:

The beamway can

(with short wagons) be used in cities, also in old, compact cities:

No houses must be removed, no street or road be closed.

The

normal commuting radius may then exceed 100

km. The same region size will be achieved also for airports and

hospitals, into which the trains may enter. Medical personel,

patients and equipment may then be sent between hospitals

like with the latter's pneumatic tube systems.

Why Lightweight

Rail?

Traditional

railway is heavy-weight, designed for each wagon to carry 125 tons

(Wikipedia).

The real requirement for passenger, express and local trains is 6-8

tons, and such a wagon weights 40 tons. This is a tradition which is

based upon the assumption that flat ground may be appropriated and

reserved for the railway. Where this is possible, the consequence is:

All ground transport must be in one plane. In more awkward locations

(like coastal Norway) the consequence is: No railways at all.

Politicians

evaluating high-speed rail for passenger transport should have

experts on passenger transport. But they only have (or use) experts

on heavy freight, and these assume that their rail concept is

appropriate for transporting passengers, when less than 10% of the

weight load capacity is utilized. The consequences of this assumption

is not analyzed.

The minimum weight

for trains running on the ground was demonstrated in February 2007

when a train was derailed by snow masses on a Norwegian mountain

line. The train — called a Signature train — consisted of

motorized wagons, each with 72 seats and weighing 54 tons. A local

train expert told the media that he had warned against using such a

light train, as it could slide like a snowboard and derail. A heavier

locomotive, which could push an efficient snow plow, should be used

in front. In warmer climates, where snow masses may be disregarded,

trains must still be built to survive collisions with cattle and

other large animals, as well as crossing road vehicles. If the track

were replaced by a beam running 6-8 meters above the ground, resting

on pillars, both snow mass disturbance and collision danger would be

virtually eliminated, so now lightweight technology could be

employed. A positive feedback is encountered here: Rail elevation

enables light trains, and light trains are easy to elevate above the

ground. (Such positive feedback situations can create quantum leaps

in technology, and this effect seems to be effective here.) An empty

wagon for 70 passengers needn't then weigh 40 tons – perhaps

only 5.

The reduced weight

leads to improved fuel economy and reduced emissions, as well as

simplicity and reduced costs for bridges and other railway

installations.

Having the

lightweight rail "upstairs", enables it to be placed above

existing roads and road bridges. It can also take shortcuts over

rivers, lakes, agricultural areas, parking lots, garages, streets,

pavements... Complicated compulsory purchase processes may be

replaced by simpler economic compensations.

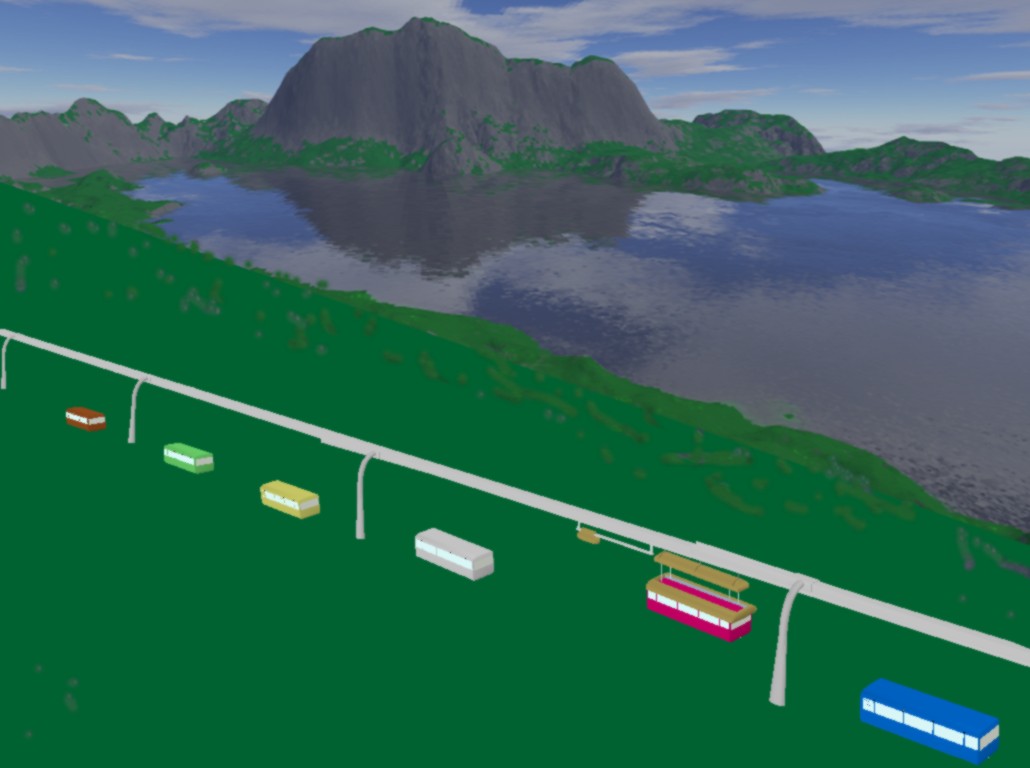

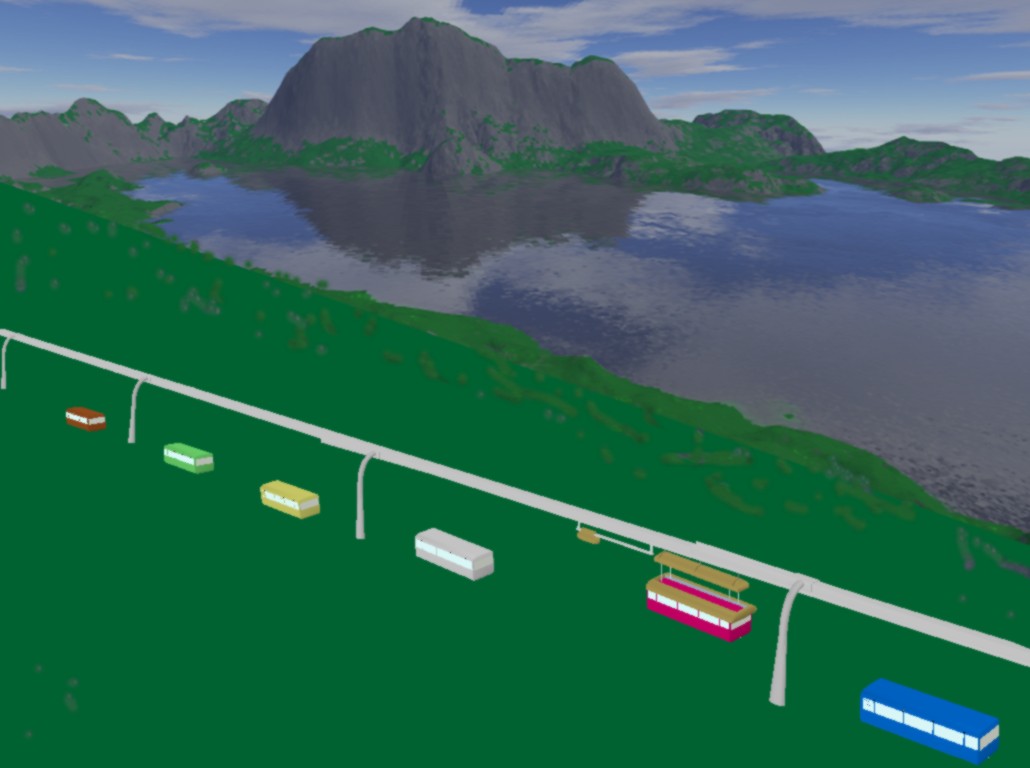

The Beamway

(a suspended train, running in a steel beam):

99 % less

ground razing and barrier formation

(Scenery

photo: Freephoto.com)

It is highly

unlikely that something will get in the way of such a train. It can

consequently run at high speed, also in densely populated areas. And

it can be driverless, the way the suspended trains in Dortmund and

Düsseldorf do. Low passenger capacity in each train may then be

compensated by frequent departures. It is better for the passengers

to have a small train each 15 minutes than a large train every hour.

The passengers may then choose between fast trains with few stops,

and slower trains with many stops.

When transport of

passengers (along with mail and other light goods) need only 1/15th

of the weight capacity, it should be clear that an

alternative rail type should be considered. If freight trains must

keep adapting to the needs of the passengers, the transport capacity

cannot be efficiently utilized. To upgrade conventional rail for fast

passenger transport can easily become more expensive than a separate

light-weight rail, so why settle for a compromise railway when two

efficient can be had instead?

The Monorail –

always Exiled to the Future?

The

monorail is a light railway running on a narrow-gauged track which is

on or inside a rigid beam. This means the track needn't be upon the

ground, but can run on top of poles, so that it doesn't conflict with

constructions, activities and the nature down on the ground.

Conventional railway, on the other hand, will normally require a

reserved area which can only be crossed by other traffic on certain

places. The train doesn't have to balance upon the beam, so this can

be narrow and thick (high). It can then really function as a

load-carrying beam. The lightweight rail will then become a monorail.

Monorails in general are thoroughly described here.

There are two main

types of monorails:

The

train straddles the beam, so that it is stable and secure against

derailing, by having each wagon's chassis divided in two by the rail

and stretching somewhat down on both sides of it. The beam of this

(type ALWEG)

prevent vertical passenger movement towards and from ground level,

so this kind of railway require elevated stations unless the station

areas are reserved for this purpose. Snow and ice may obstruct the

beam, and birds perching on the beam are likely to become massacred.

The train is

hanging under the beam. The wagons are hanging below 2-4-wheel

bogies (trucks) which run inside the hollow beam. Wagons (or an

elevator built into a wagon) can consequently be raised or lowered

with arriving or departing passengers. With a hanging train, the

passengers are not exposed to the sideways-acting forces they else

must endure when the train speed doesn't fit the banking of the

track.

Besides, a beam can hang under a simple row of cables

when the train is out of the way.

These advantages are the main

reasons for us to concentrate upon this type: the suspended beamway.

The

beamway we are going to discuss, is of the type SAFEGE,

a French design from the fifties. Such a railway was tried in France

about 1959-70 (and shown in the movie Fahrenheit 451), but wasn't

successful. The Safege technology was later sold to the Japanese, who

used it for some local railways. (See a movie cut here.)

The beam/rail

design is called SIPEM, and is developed by amongst others Siemens.

The

Swedish Swedetrack Systems AB has here

presented a description of their FLYWAY concept. My discussion and

ideas mainly take this description as the point of departure, but has

a different attitude towards the means of conveyance: Swedetrack's

FLYWAY-description is car-biased, while the present discussion is

bus/train-biased.

Car or Bus?

Visions about

future transportation systems often start with assuming that the car

is the preferred means of transportation, but regard the conveyor

belt principle to be needed for managing the flow. This is also the

point of departure for FLYWAY, which depicts and describes

essentially small passenger cabins. The largest cabins are for 32

passengers, but also these are treated like small private cabins: The

entire cabin is lowered whenever somebody is entering or leaving, and

such a bus ride would be quite annoying. Small cabins with 2-6 seats

pose the problem: Shall they be private like taxicabs, or are

strangers supposed to mingle? Such mingling would give personal

security problems in small cabins, but is safer in larger, bus-sized

cabins. It stands to reason that taxis are private, as they go all

the way to the destination building. But when the stop has to be

somewhere along the track – and perhaps only at designated

stops, it becomes meaningless – and perhaps dangerously

confusing – to privatize cabins. The fear of strangers is

intricately connected with society splitting and Hollywood

dramatization, but should not preclude future visions involving

public transportation.

Regardless of the

cabin size, the danger of vandalism should be taken into account.

Both personal and material security can be improved through video

surveillance, but it is of little value that a situation is

immediately perceived in a security central if it takes more than ten

minutes before somebody can act where the action is. Personel on the

train may be using the same video images, but if they sit in the next

wagon, they can be far more useful.

Visions of future

technology tend to be far more optimistic regarding human nature, but

nevertheless: I will assume we will need vehicles emulating

conventional trams and buses, and with a centrally positioned

conductor.

Transport visions

tend to forget an important point: That travellers need access to a

toilet. Also this calls for the bus size.

But

private cabins may be used for special purposes: Transport of

patients and medical personnel can be automatized and function like

the pneumatic tube systems in hospitals. And mobile

services should be able to have their service cabins dispatched

around in the beamway system. It is also useful to let the beamway

transport camping cabins to and from

camp sites, and transport boats

between storage and sea. Besides, wagons for mail

and other light goods could go along. In some areas, private

pods (cars/cabs) may swarm. This may occur in the same beamway

line system, provided there are enough sidetracks to prevent train

traffic delays.

Quite many (half)

private wagons may use the public lines if they are scheduled to move

in caravans.

It is very

important for beamways that the cabins will not be overloaded by

chaotic crowds (at rock concerts, sport events, ...). Here are two

ways to avoid this:

Use special

stations which have a solid platform immediately under the cabins.

If a cabin is overloaded, it sits down on the platform and stays

there.

The passengers

are admitted through a sluice system which automatically closes all

access during an overload situation.

The first station

type is suitable on special places (like end stations) where the

traffic is heavy, but leaves the problem with throwing out some of

the seated passengers. If the beamway contains an elevator, it will

be able to stop for arriving and departing passengers almost

anywhere, and at the same time have an excellent sluice mechanism

which automatically refuses to raise an overloaded elevator, or to

lift passengers up to a train which is becoming overloaded.

Such a sluice

would also make it difficult for terrorists to place their packages

and immediately leave. If all luggage items are registrated when

passengers are admitted, it should be possible to detect if anybody

tries to leave without all their luggage.

Container

Transport of People?

Transport

of goods became far more flexible and efficient after the

introduction of intermodal

freight transport, which is based upon use of containers, easily

transferred between different means of communication.

It is now natural

to ask: Could similar efficiency gains be obtained with passenger

transport? The concept of intermodal passenger transport

implies merely a short walk between the modes of

transportation.

The main

advantages would be:

Better travel

opportunities for disabled people

Less fuzz with

luggage handling

Saved time –

the slowest passenger determines the delay

Repeated

passenger controls are avoided

Most passengers

would undoubtedly benefit from using their legs, but they should get

opportunities for this in other ways.

Transferring

containers involves slow operations with cranes, and stacking the

containers in ships and harbors. Passengers can't be subjected to

this: For passenger cabins, smooth and swift transfer is imperative,

without cabins dangling under cranes.

Transport by both

ship, railway and road imply placing the cargo on horizontal

surfaces, so each transfer involves lifting the cargo, moving it to

another surface, and putting it down there. There is a need for a

means of conveyance which can deliver cabins from above and (with

minimal movement) directly to a receiving surface, and vice versa.

This is the way

the suspended train of the beamway operates, and that is one of the

reasons we will take a closer look at it.

Recommended

Beamway Design

The main

principles for the recommended beamway design will consequently be:

Start with the

FLYWAY design, which states that an 80x80 centimeter beam can carry 7

tons if the distance between the poles is 30 meters. Then add the

following set of improvement proposals:

Let the beam go

from pole to pole without a joint. The joints should come at the

poles, where it is easy to place heavy and balanced splints –

fortifying side plates which go along the beam, strengthening it like

the splints placed along a broken leg. If they fortify really

efficiently, we could, with 20 meter long splints, sort of have 20

meter wide poles, so that we could have one pole every 50 meters

instead of every 30. It may, however, be more realistic to assume

that this pole widening is done only half ways, so I will tentatively

assume one pole every 40 meters.

When the beam is

forced to be horizontal (or with another precise inclination) near

the poles, it will not be able to sag much down near the middle.

Besides, the whole beamway structure is strengthened and able to

withstand e.g. emergency braking.

It may seem

strange that the FLYWAY concept, for up to 7 tons, can be used for

long trains with several times the weight. But a long train will have

only a small fraction of its weight in the weak central part of the

beam, especially if it is designed to function as a movable beam.

This beam will have a stiffness which adds up to the stiffness of the

beam, so that mainly the poles will get the weight of the train.

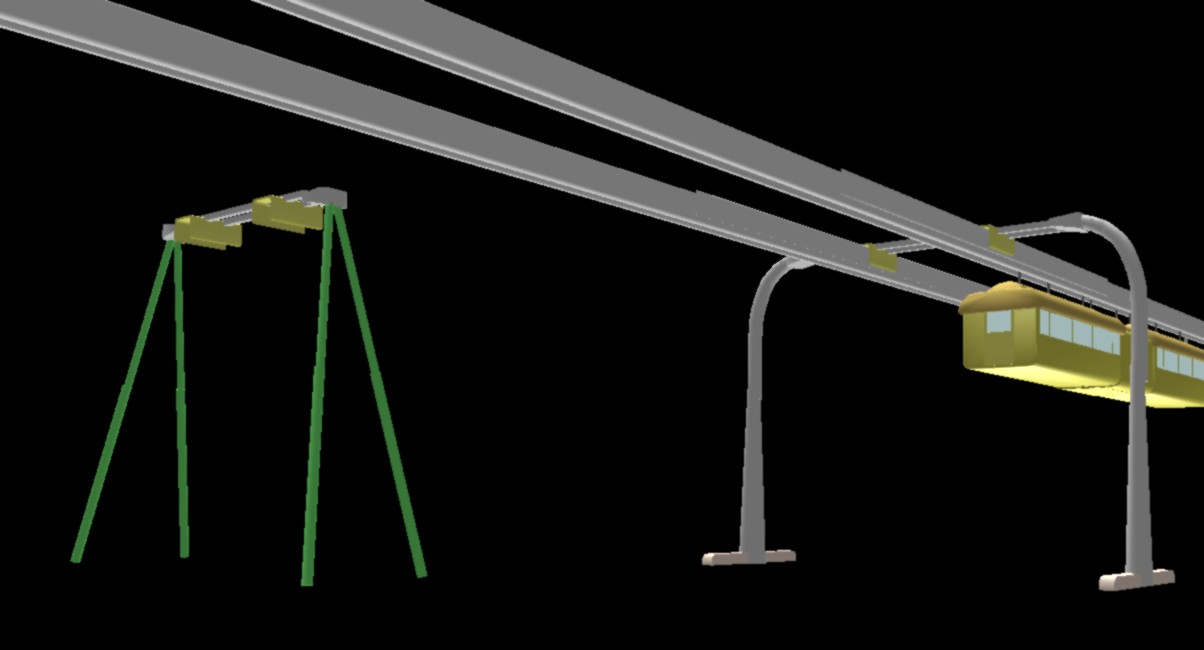

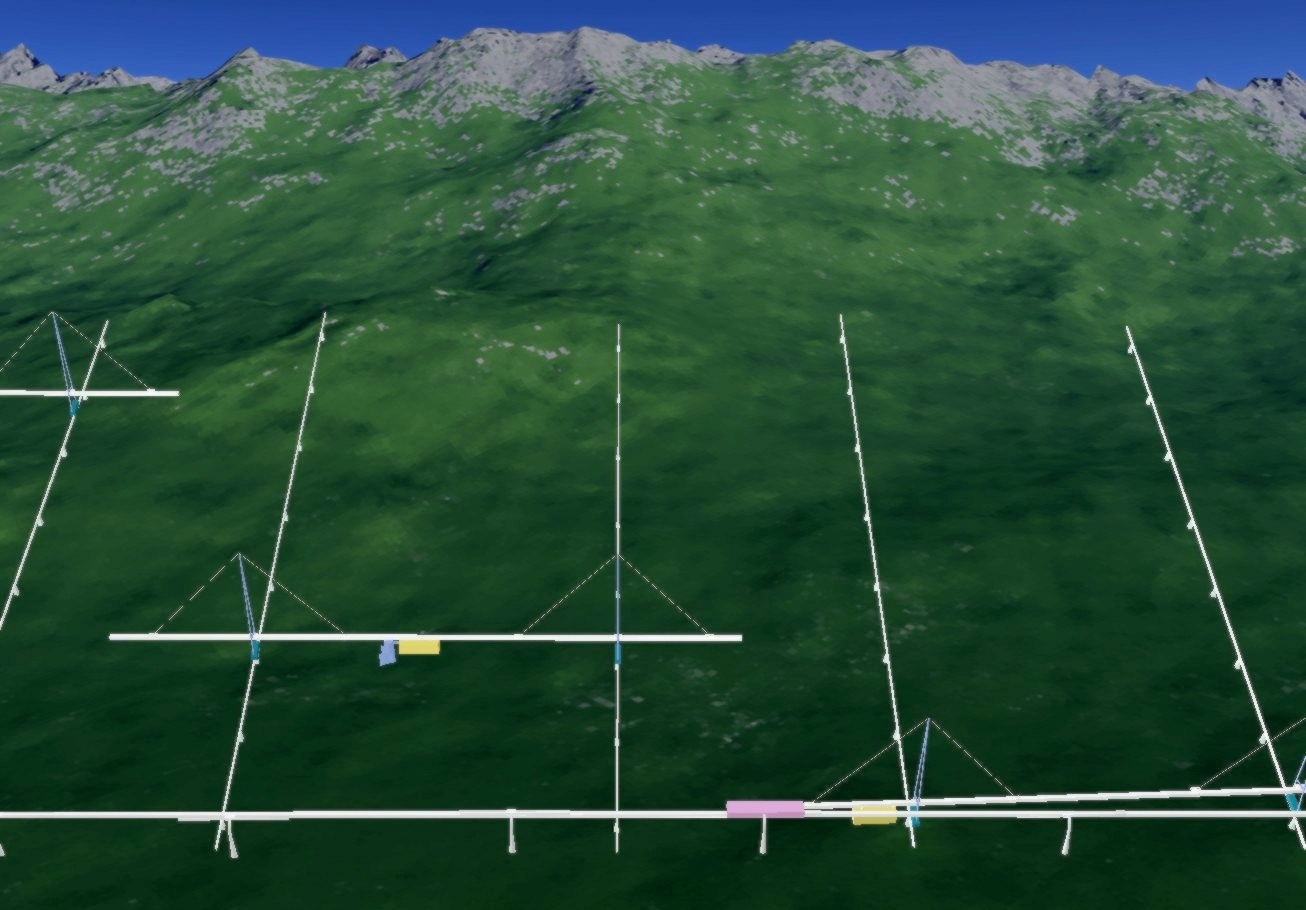

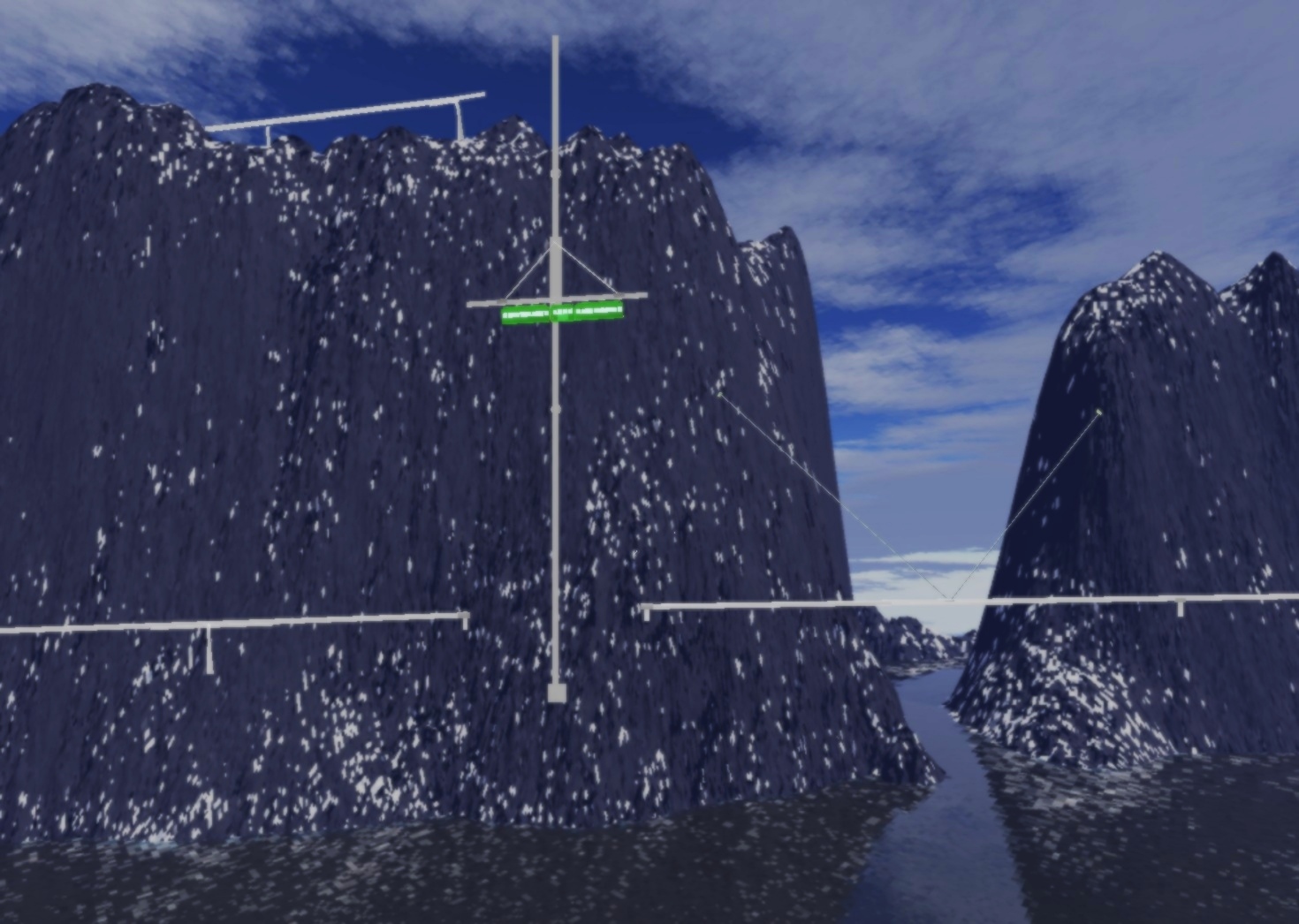

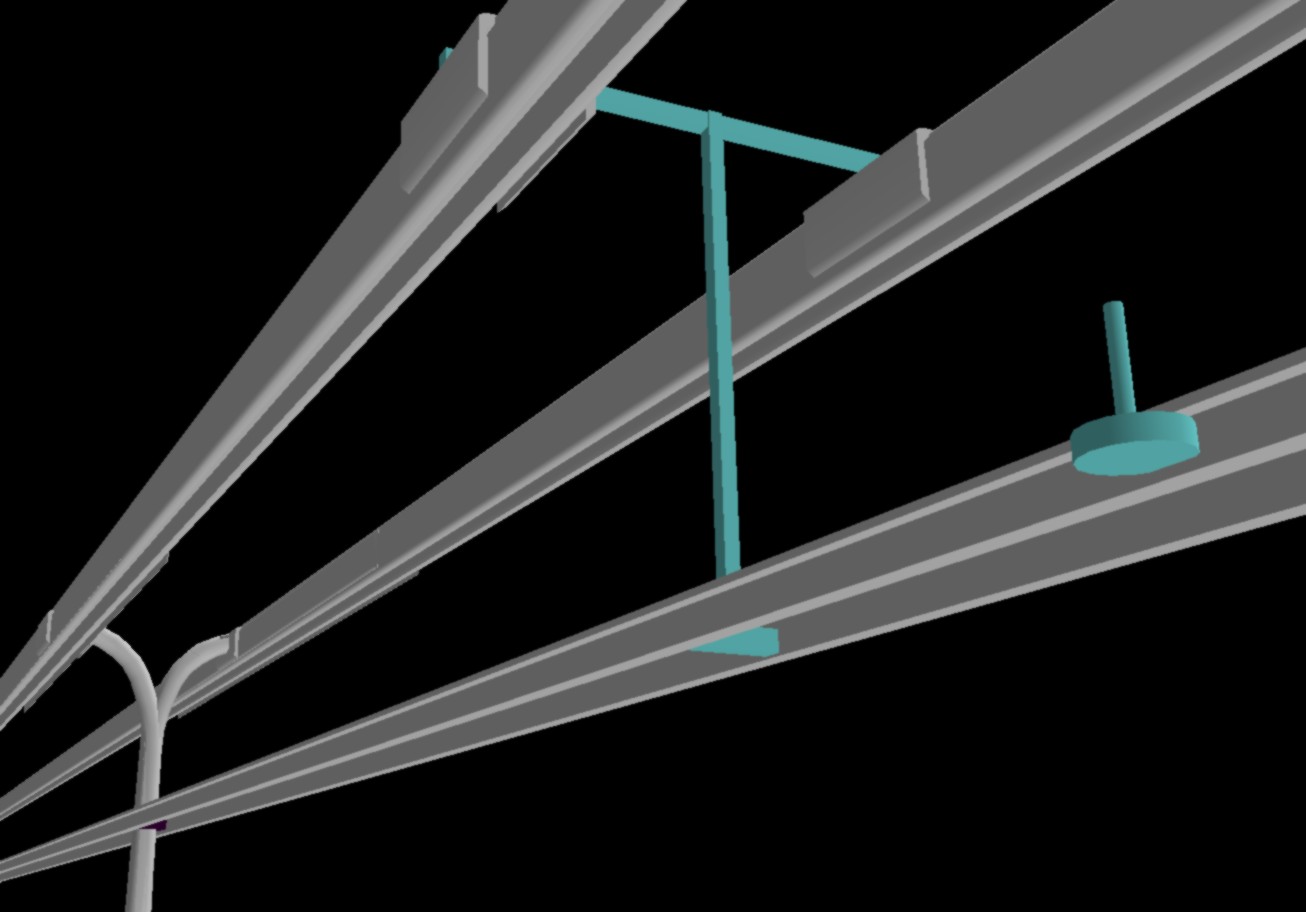

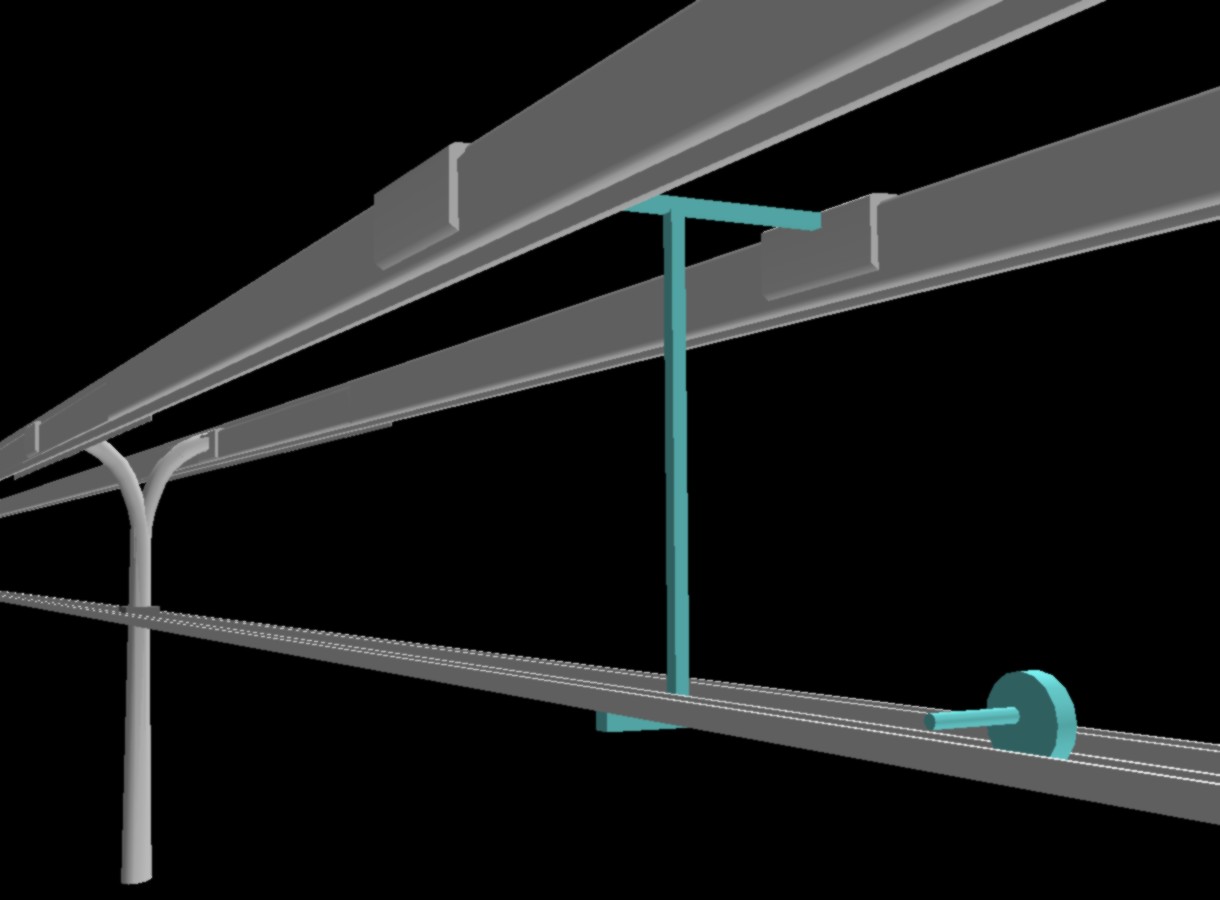

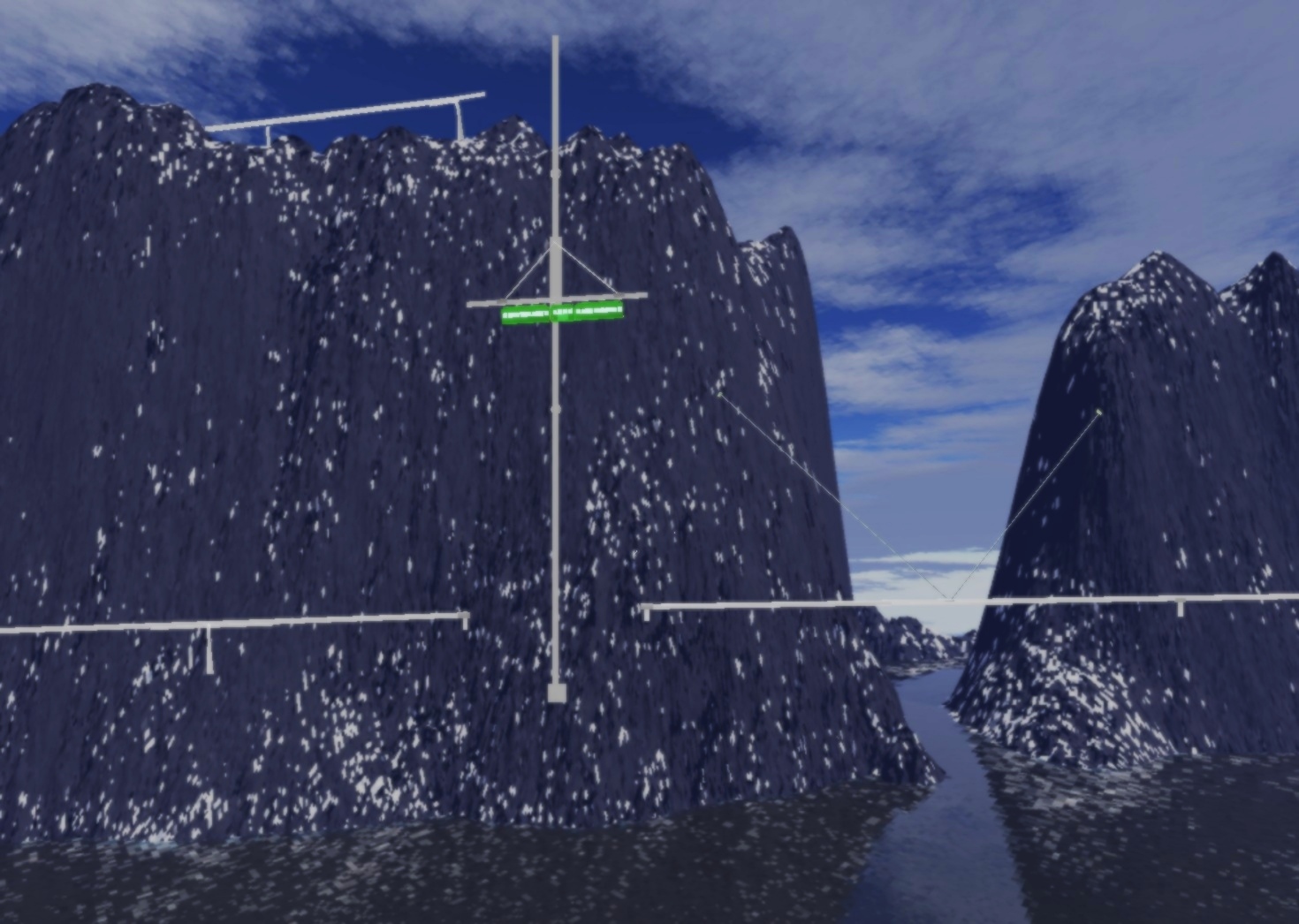

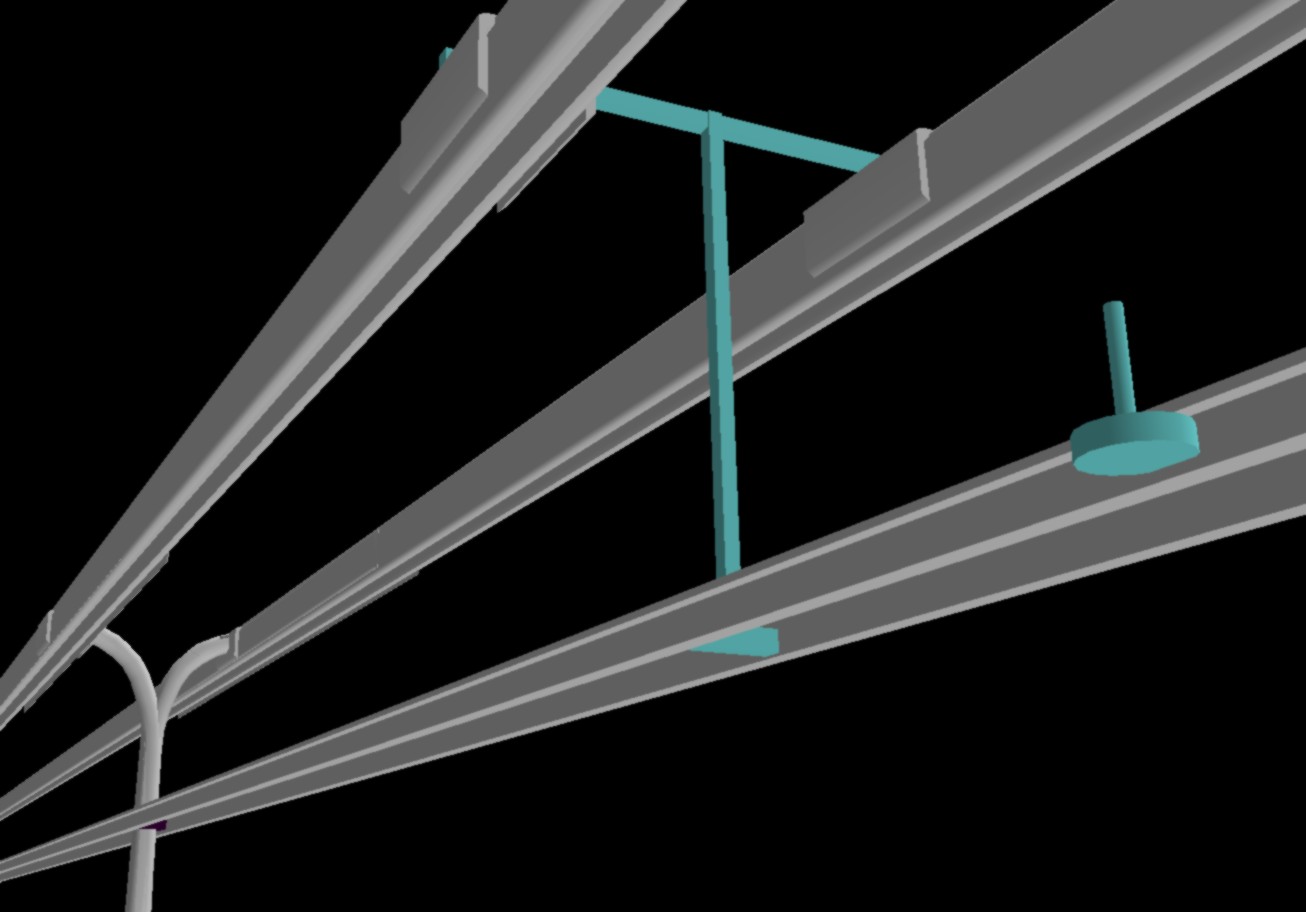

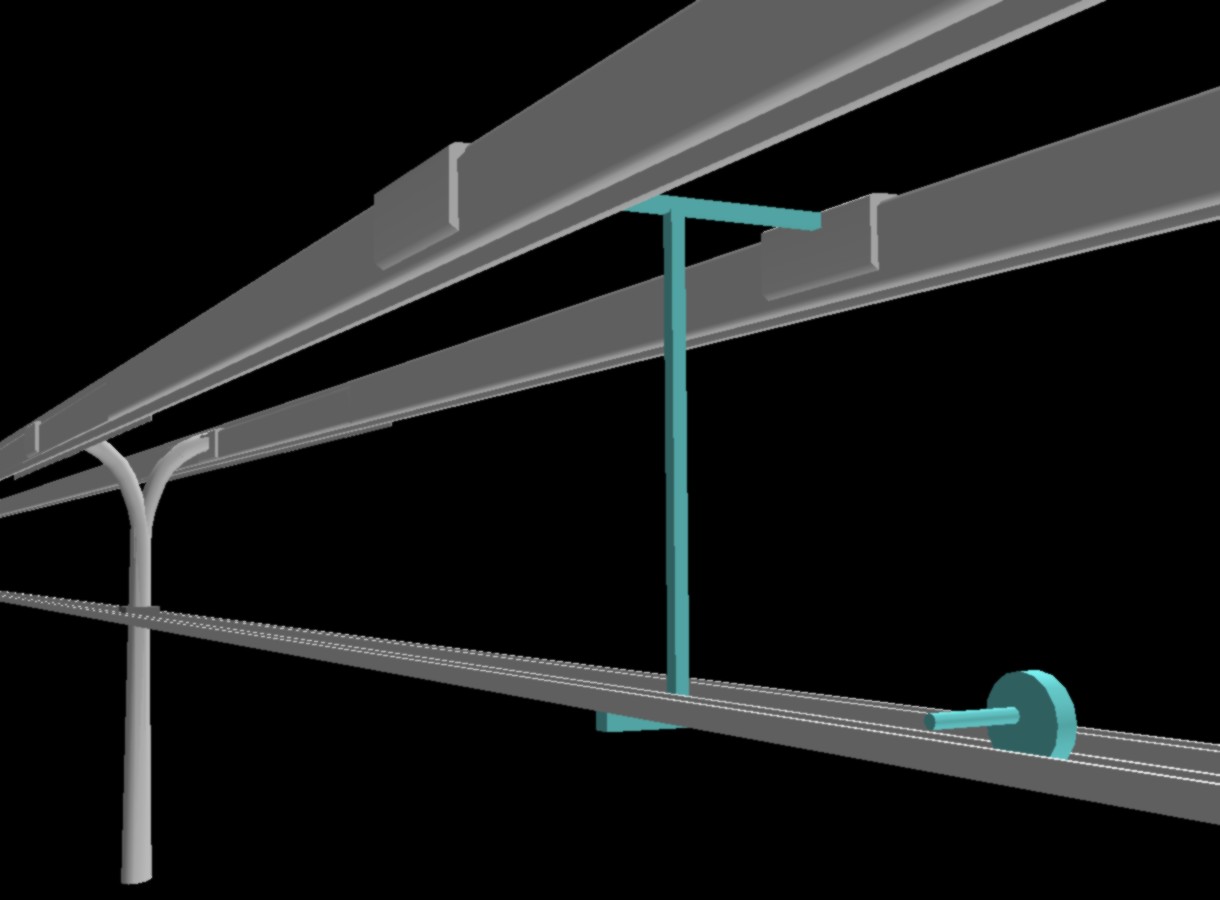

The Poles

The poles carry a

bracket or a small platform which on its lower side (inside) carry

the ends of the half-beams, and a splint on the sides of a beam

joint. The beams are not assumed to have exactly the correct length,

so there must on both sides here be a holder for a small rail piece –

e.g. 1-80 cm. Some places a service platform may be needed, so the

gap between the beams must here be so wide that the bogies running on

the track can be lifted out.

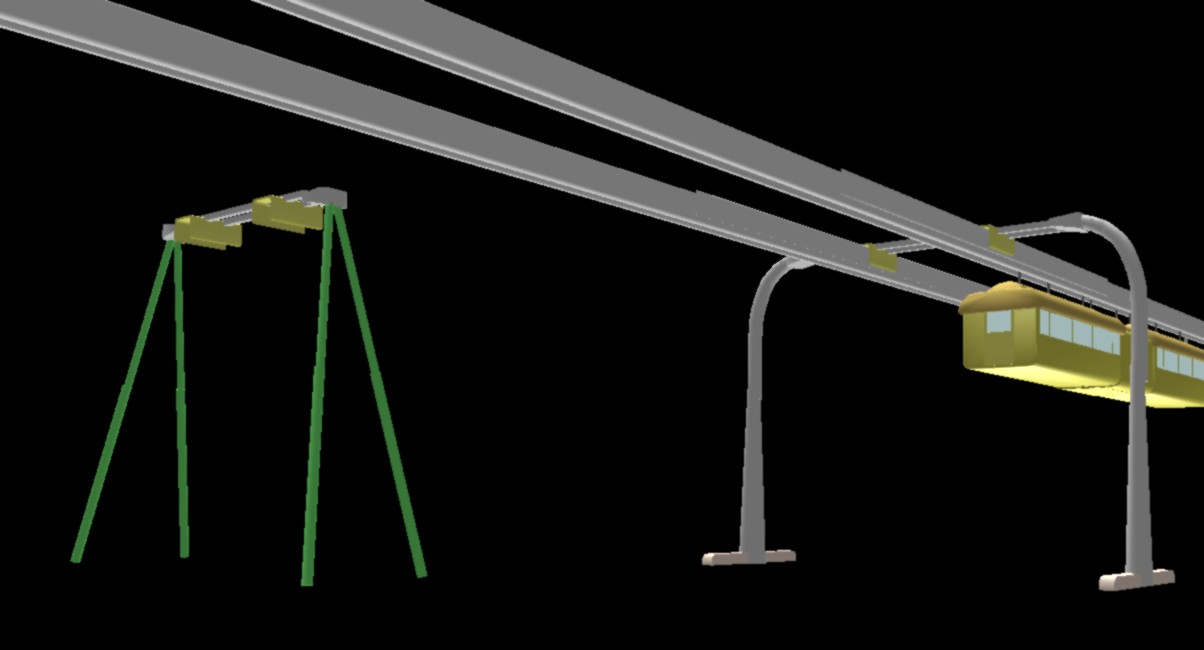

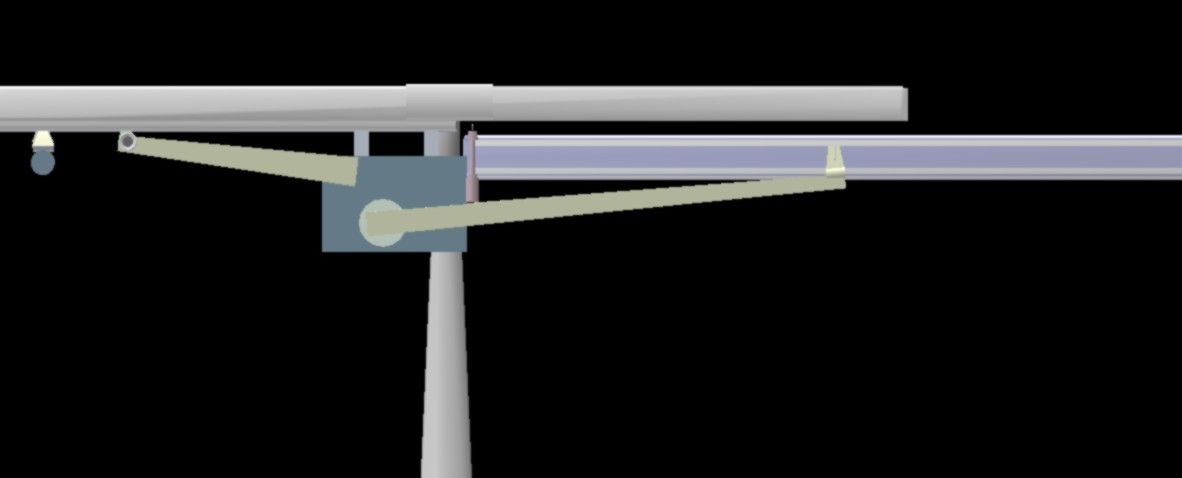

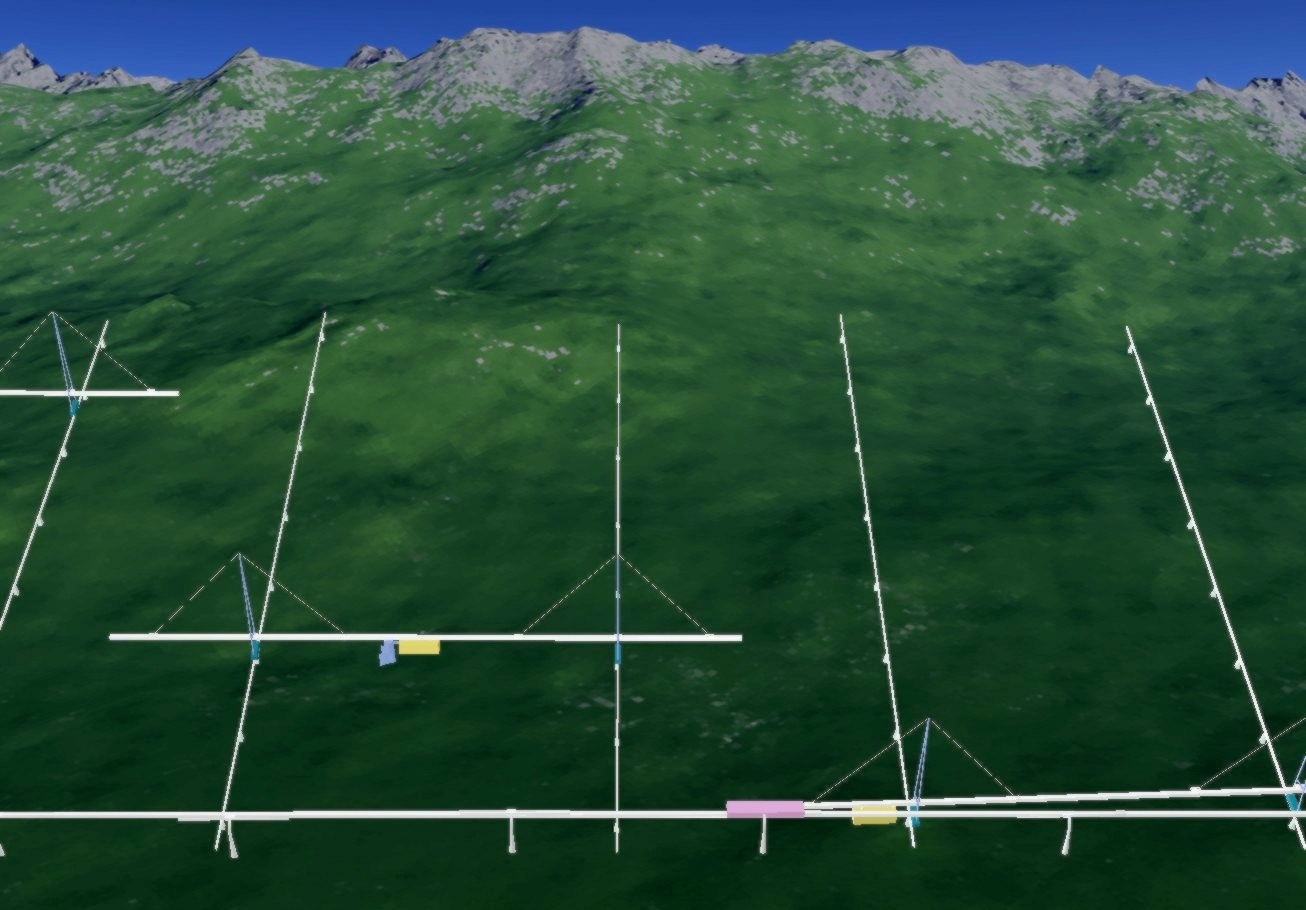

A pole should

be prepared for expansion from single-tracked to double-tracked

operation, carrying either simultaneous traffic in both directions,

or letting parts of two different lines follow each other for a

while. The pole should then on its backside be able to carry an

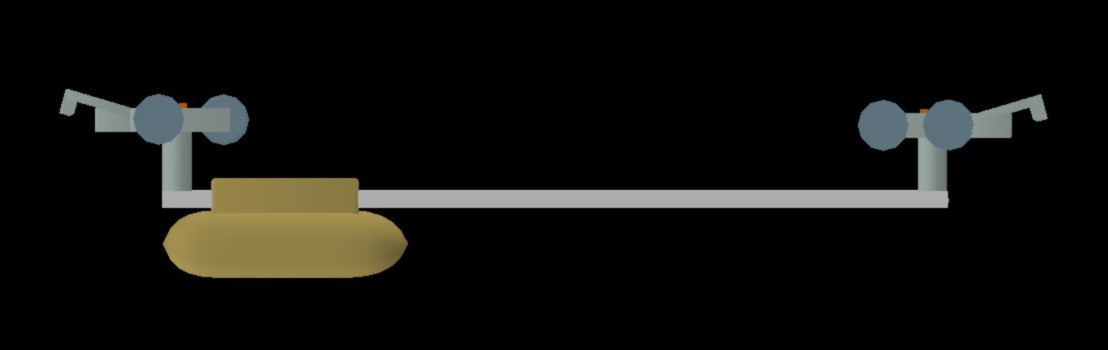

additional beam holder – seen in the background here – so

that the pole has traffic on both sides. Another alternative is that

two poles are mounted with meeting beam holders, or a long common

beam holder – in the foreground here – so that the whole

assembly form a bridge which can carry a double track beamway along

and above a road.

If the two

poles have side support legs as shown here, a stable and movable

stand is obtained. This enables provisional beamway lines, which may

e.g. be moved to the side if the beamway gets its own tunnel.

It should be

possible to attach the beamway to the facade of certain structures

like large garage buildings.

A line of

windmills should also be able to function as a row of beamway poles,

and the two systems may cooperate about power lines.

The Beam

Beam joins should

not occur between the poles, only at them – between the

splints. But a 40 meter long beam would still not be too

unmanageable, as it is divided in three parts lengthwise: Two

C-shaped half-beams, both symmetric and exchangeable, supplemented

with a connecting and protecting plastic part which contains the

power line.

As the power line

is surrounded by iron, a good shielding of the electromagnetic fields

is achieved, in contrast to the freely hanging power line of

conventional railway, which causes strong electromagnetic pollution

of the environment.

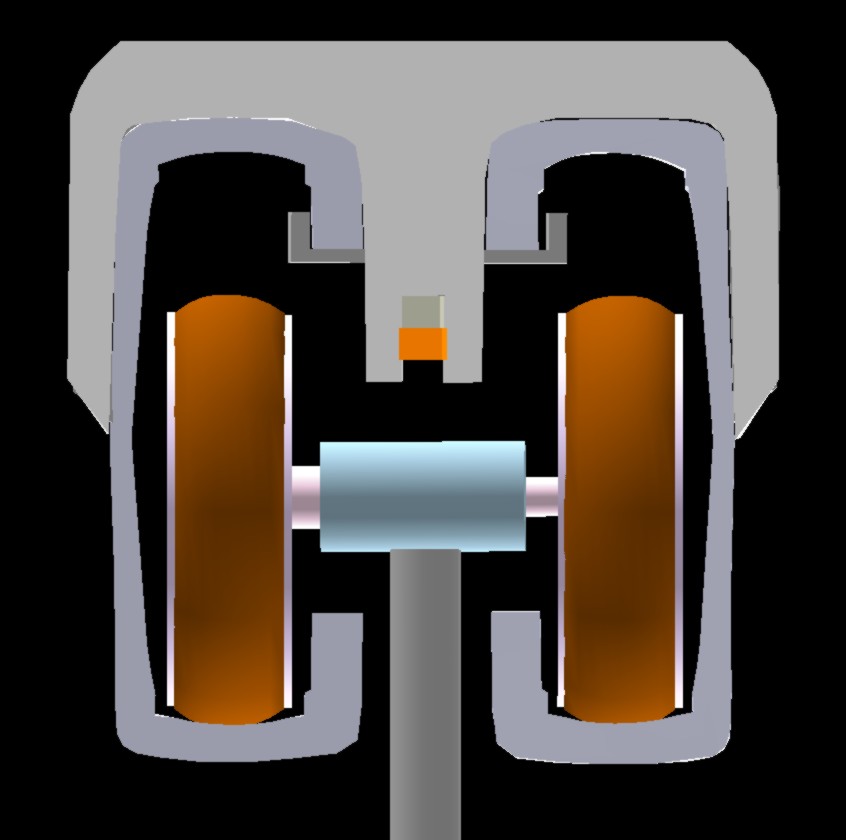

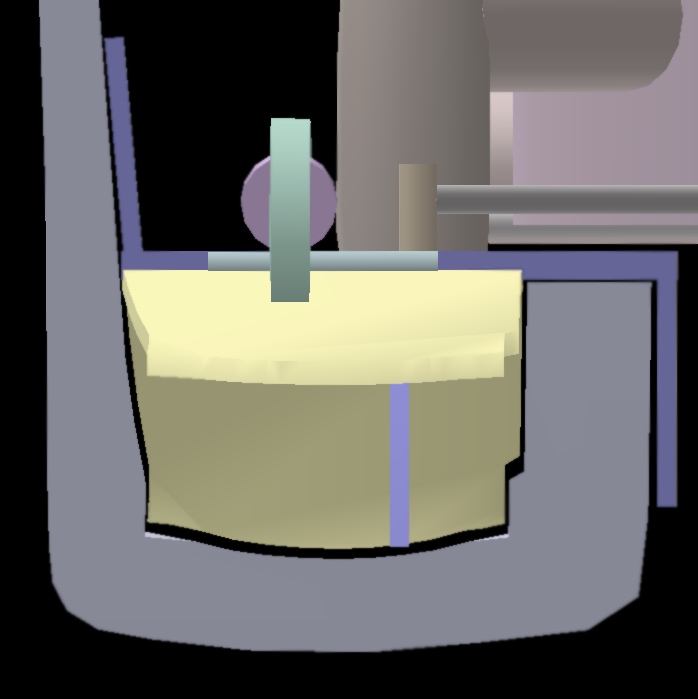

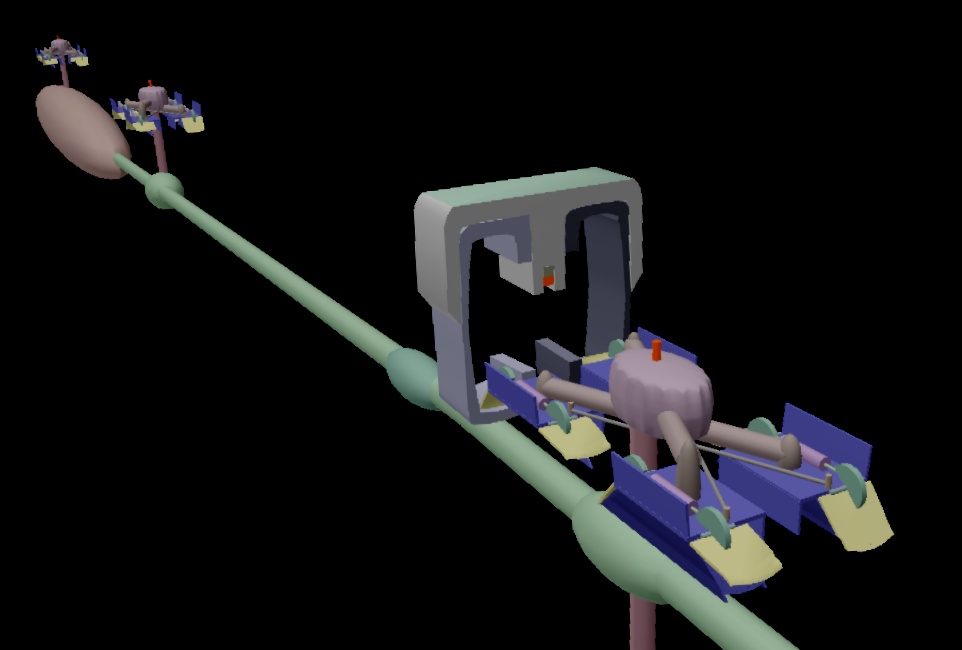

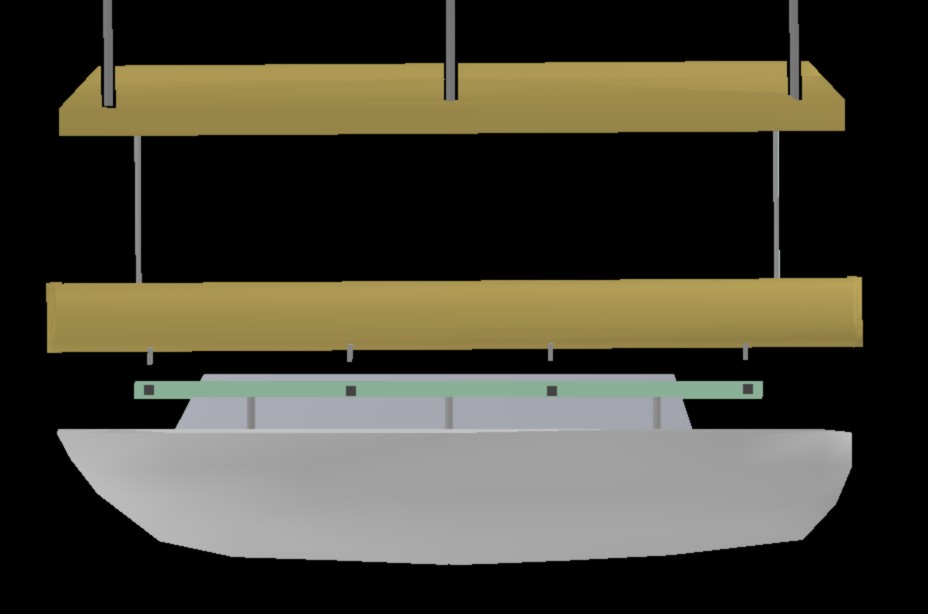

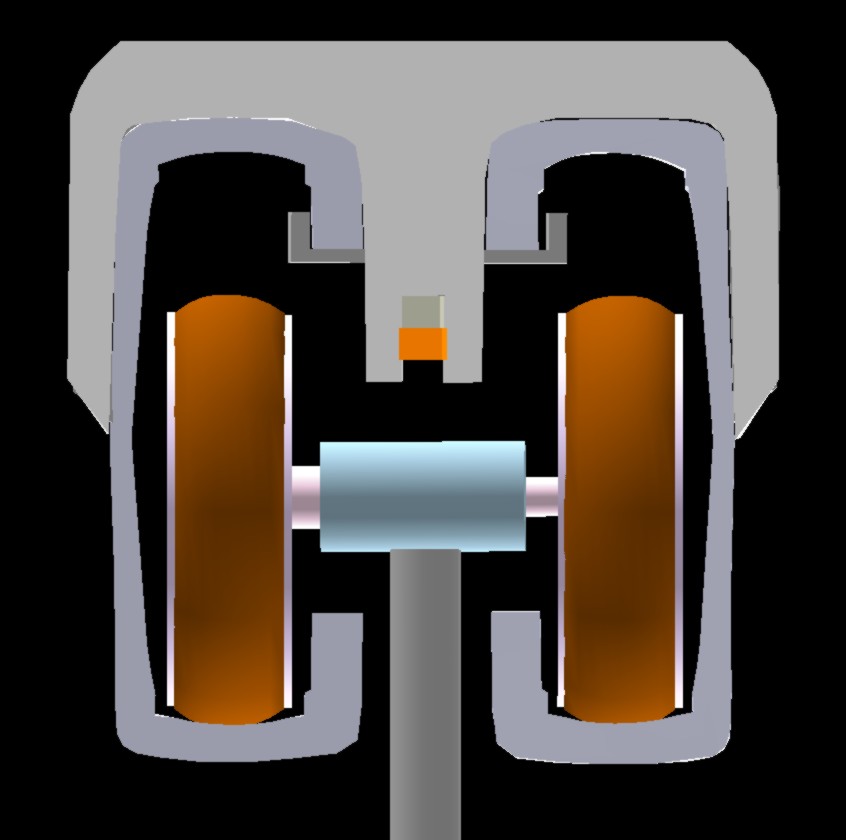

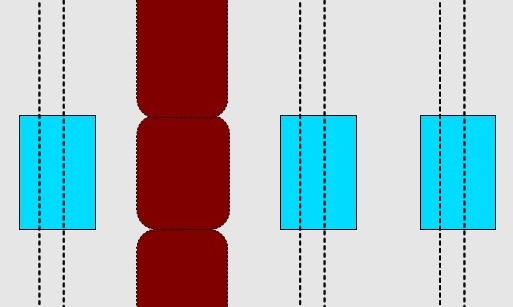

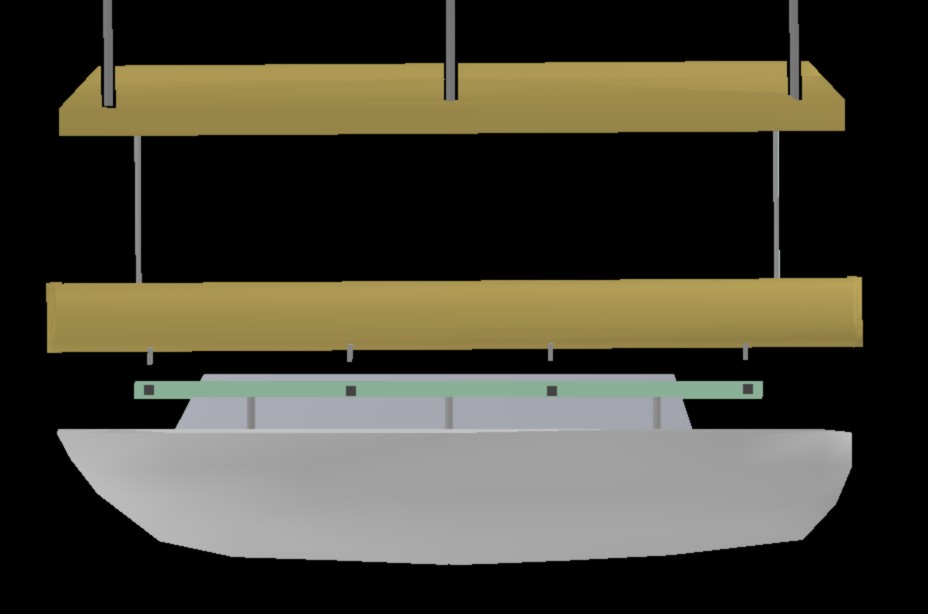

Section of the

2C-beam. The power line is in the middle.

Left: We see how the

wheels (for slow local trains) run in the two C-shaped half-beams.

Right: Air cushion drive (for high-speed trains) with the same beam.

The air cushion is trapped under a steel lid (blue), and between two

valves (yellow). The front valve is open. The rear valve is closed,

so the train will be pulled in that direction. (The air cushion unit

gets pressurized air from a compressor loc – see under The

Locomotive below.)

Each C-shaped

half-beam will be only about 30 cm wide, and can consequently at the

line construction site be given the moderate curvature needed for

turns on high-speed lines (with increasing/decreasing curvature

before/after turns), as well as the twisting needed before and after

graded turns. If conventional SIPEM beams were to be used, they would

be about 80 cm wide, and far more difficult to bend and twist. If

they had to be factory ordered with specified combinations of

curvature and twisting, the manufacturing, logistics and line

modification operations would all be very problematic.

Having the power

line surrounded by iron, will greatly improve the shielding of

electromagnetic fields emitted – in comparison to the strong

electromagnetic pollution caused by conventional railway power lines.

When the poles

have been erected, the beamway could be built without local ground

support: The half-beams are transported along the finished part of

the beamway. At the end of the stretch, hangs a crane boom which

lifts a (left or right side) half-beam up to proper alignment, being

partially affixed at both poles. This operation is repeated for the

other half-beam, and workers on or at the rear and front poles fasten

the half-beams more thoroughly. The crane boom is then moved forward

on the new beam stretch, and the operation is repeated.

A half-beam is

here lifted up to its correct position

(Detailed

description here)

If

the monolithic SIPEM beam were to be used, a beam length would be so

heavy that beamway lines could have been constructed only on sites

accessible to heavy mobile cranes. Or the beam would have been

weakened by many splices between short beam stumps. The 2C beam can

be without full splices, as there can be many meters between splices

of staggered half-beams. (More

details here)

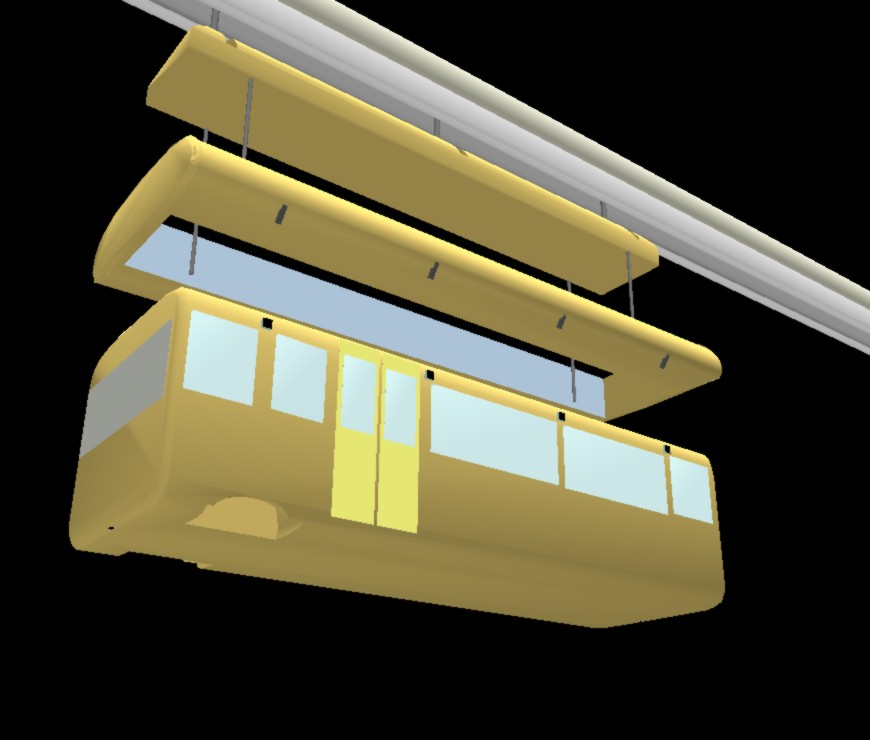

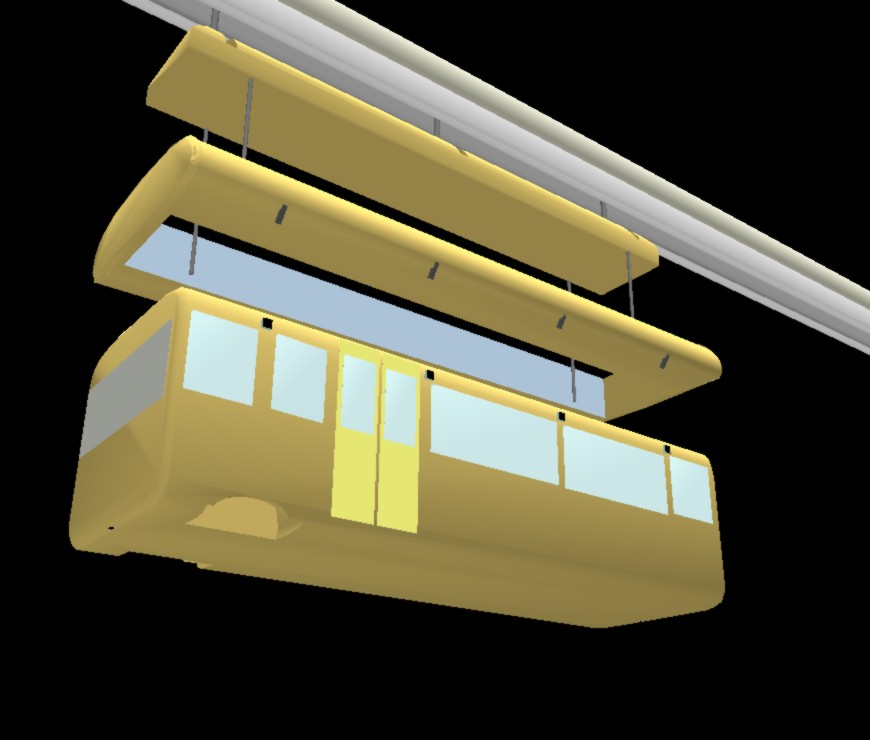

The Train

The FLYWAY concept

is about city traffic, and prefers small private cabins –

automated taxis. We will here consider another use of the beamway:

trains, capable of replacing passenger planes on distances up to

3-400 km, so the speed should be at least 200 km/h. (And the fast

trains are needed only for light-weight transport, not for the 10-15

times heavier cargo).

Heavy trains with

the same top speed will actually become slower due to low

acceleration and slow movements in station areas and other difficult

areas.

At high speeds,

the beamway has the significant advantage that it can easily get a

straight path without requiring a brutal leveling of the ground. And

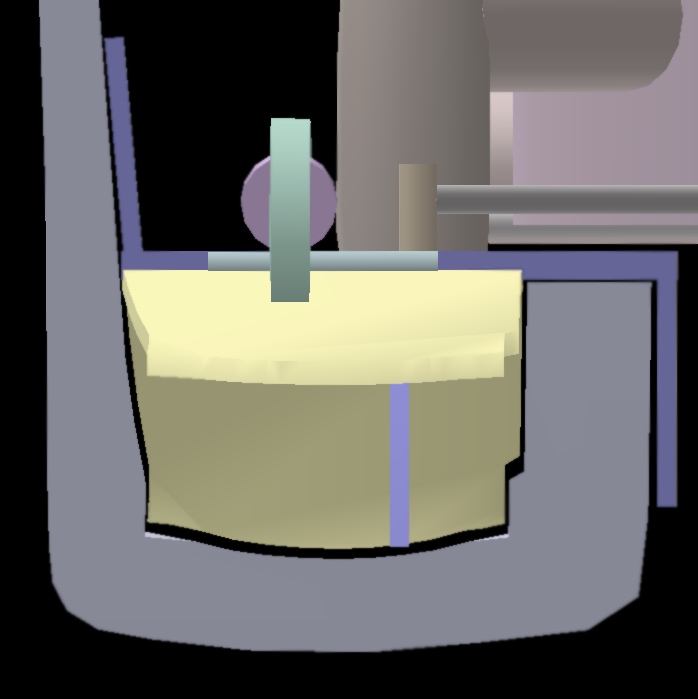

in the vicinity of the train is nothing but a smooth metal surface.

The size and

weight of the train, however, is a formidable challenge for a beamway

dimensioned for beam loads up to 7 tons. The key to designing real

trains is: to distribute the weight over a longer distance. The

starting point for the train design is: a small center wagon which

essentially is an elevator, so that arriving and departing passengers

can be transported vertically – about 5 meters – between

the ground and the train. Each end of the center wagon has a door

leading to a passenger cabin. For tram emulation the cabin will be

bus sized (8 meters), for train emulation the cabin will be train

wagon sized (24 meters). The passenger cabins may very well have a

generous seat separation, and may be sitting 2+1 abreast, so that the

weight is well distributed along the beam. (The length will still not

approach the walk through the gate corridors of an airport!)

The locomotives,

with light electro motors, can be several meters in front of and/or

behind the passenger wagons. (Such a miniloc is shown in the yellow

train depicted below.)

The train will now

become so stretched out that only a small part of it weights down the

weak mid part of the beam. A special trick for spreading the beam

loading additionally: The center wagon pulls the passenger cabins at

floor level and pushes them out at roof level.

Hopefully, the

same beam type can be used for trains and trams, so that they only

differ in the minimum curvature radius. It may be wise to let the

train have a turning loop around the city center, so that the

passengers can choose in which city part to go on or off. Or the stop

for the long-distance train can be near the stop for a city line. Or

the long-distance train can exchange a short second wagon with a city

train.

The fast trains

require larger wheels, and there isn't room for more than 50-55 cm

wheel diameter in the beams. This could give 120, perhaps 140 km/h,

according to FLYWAY. This is OK for local trains, but not for long

distance trains. Even though the wheels can run somewhat faster in

our smoothly curved 2C beam, one should from the beginning be

prepared to go for more exotic technologies like air cushion hovering

and maglev (magnetic levitation). This needn't mean trains without

wheels. A hybrid technology may be used: The weight load on the

wheels are gradually decreased by 80-90 % as the speed increases, so

that wheels can be used at higher speeds.

An air cushion in

the bottom of the beam takes over most of the weight load, and it

stabilizes the wheel between the side walls. This cushion can be

created by a compressor (in the grey nacelles located between the

wagon roofs and the beam in the picture below). Or the cushion can be

created by passive wanes leading the air towards the bottom and side

walls of the beam interior.

These

possibilities are more thoroughly discussed elsewhere,

but we may say that those working with these technologies for surface

trains, should be envious of the beamway conditions: automatically

balanced light-weight trains at a large, clean iron surface, going

above the snow and debris of the ground. Those now developing

hovering (maglev) trains are doing a grave mistake by taking

conventional heavy railways as the point of departure – without

having a need for heavy transport. It may seem natural to vary one

factor at a time, but now a double innovation is required.

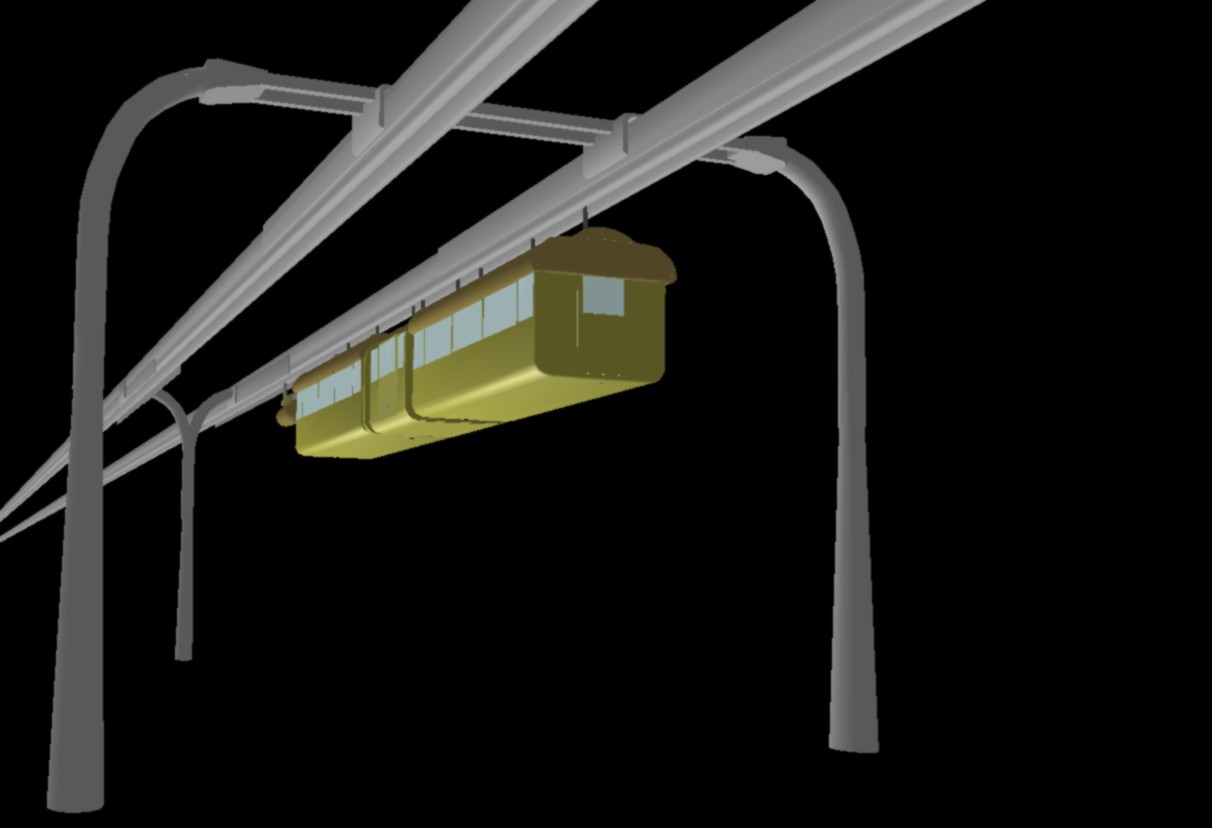

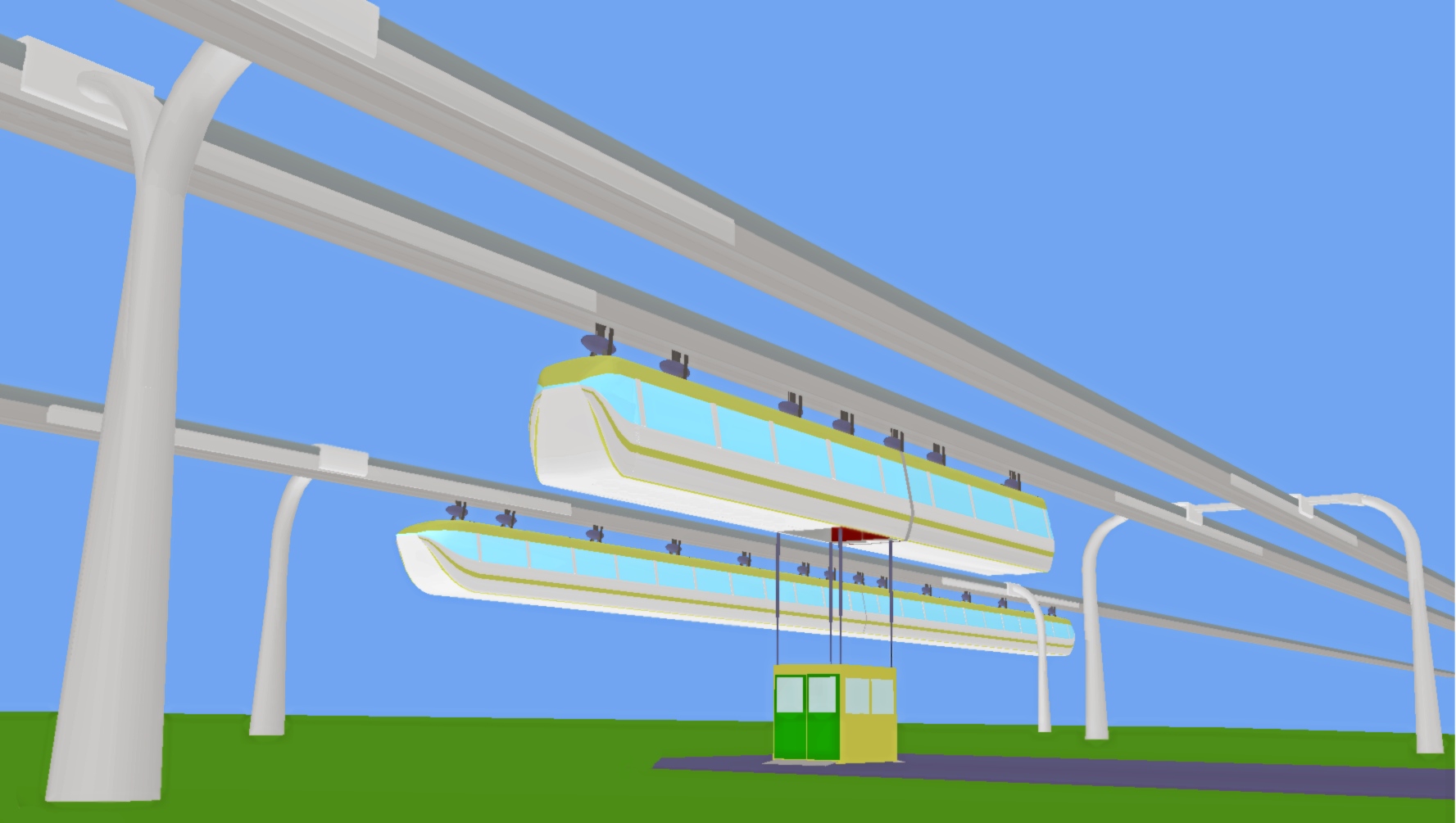

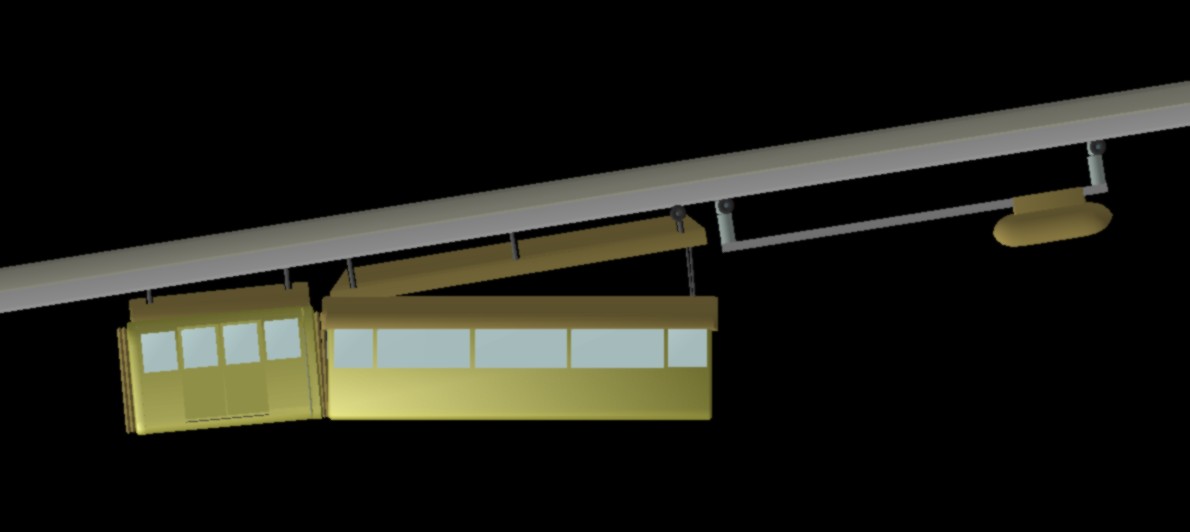

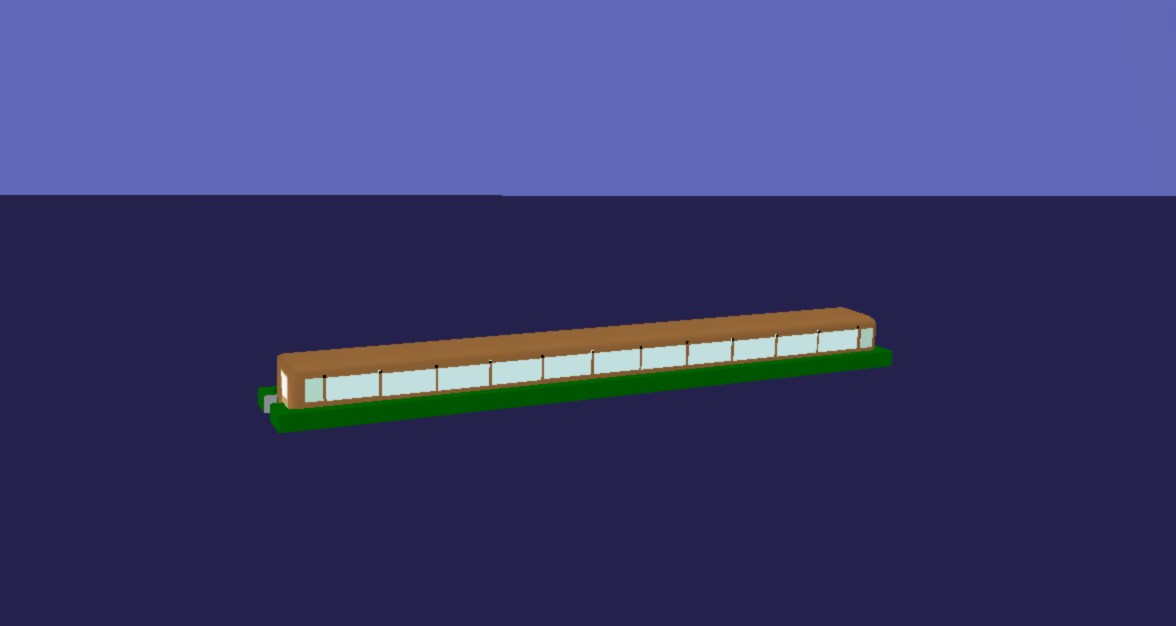

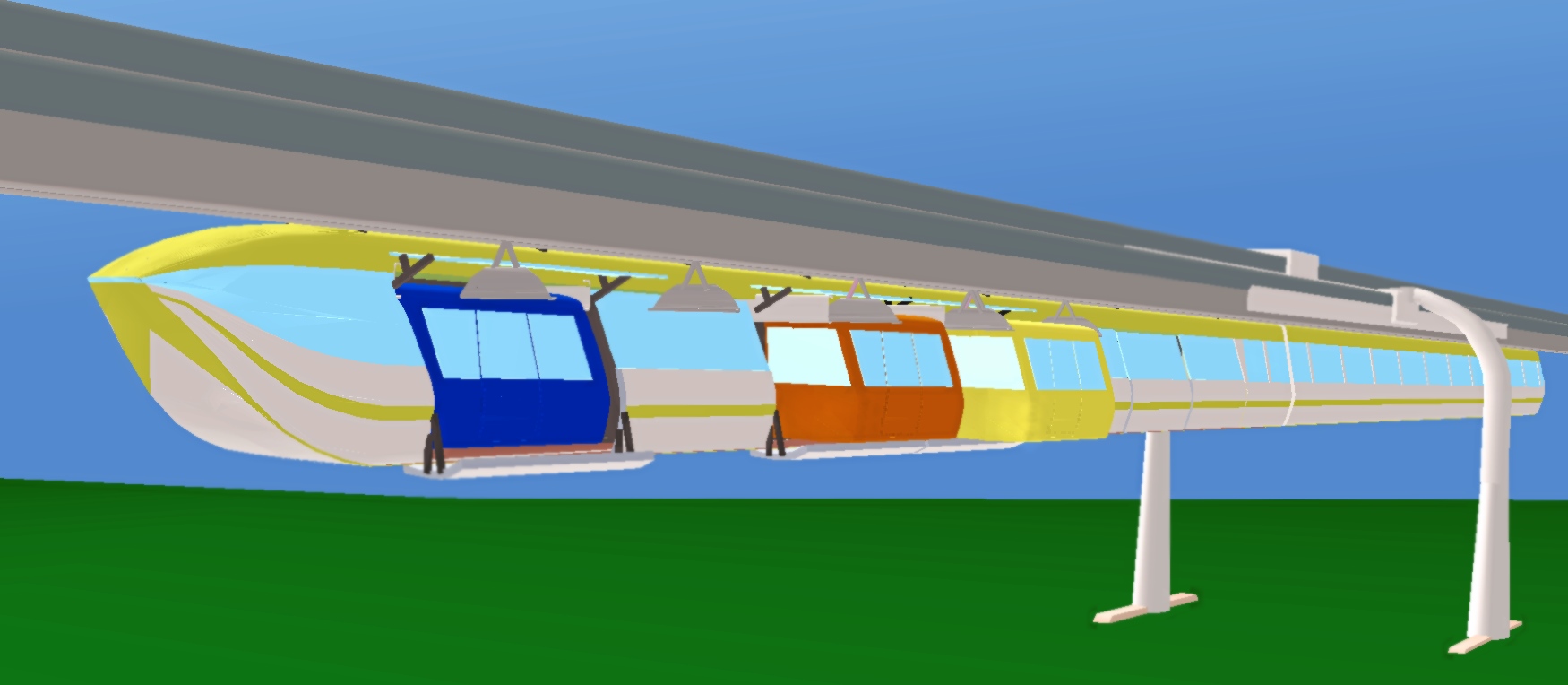

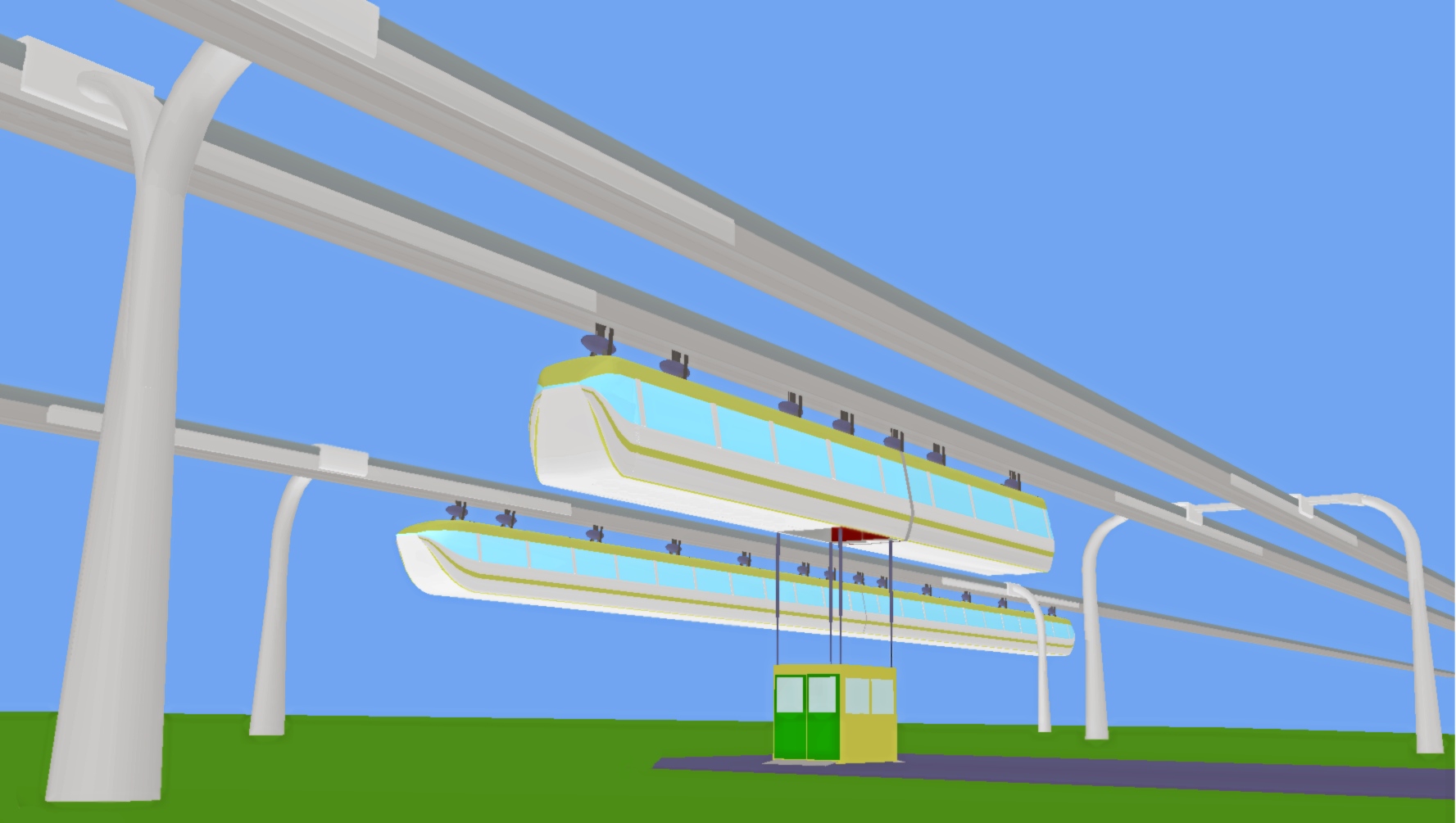

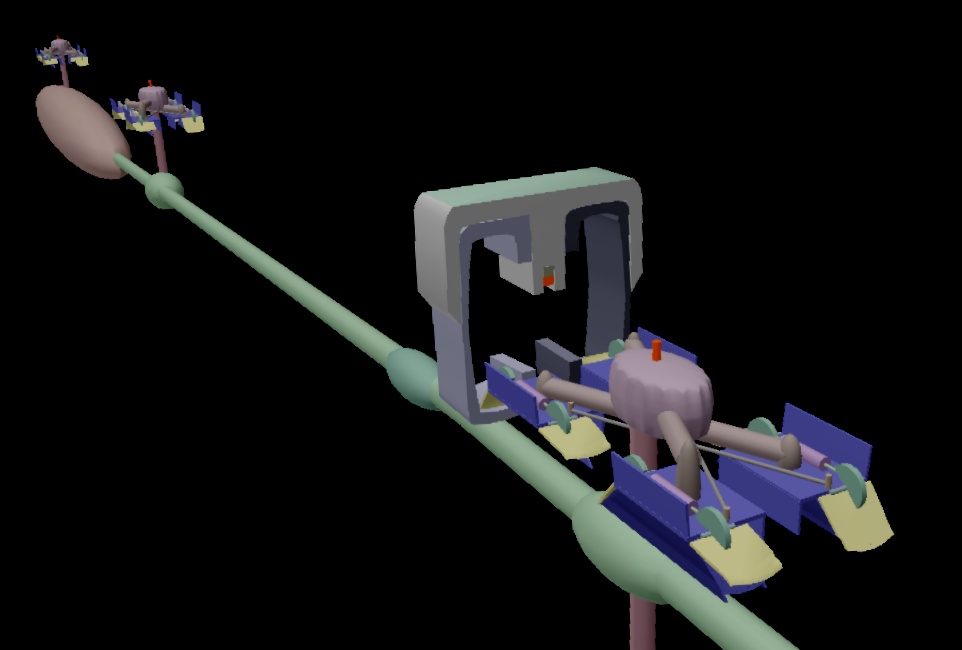

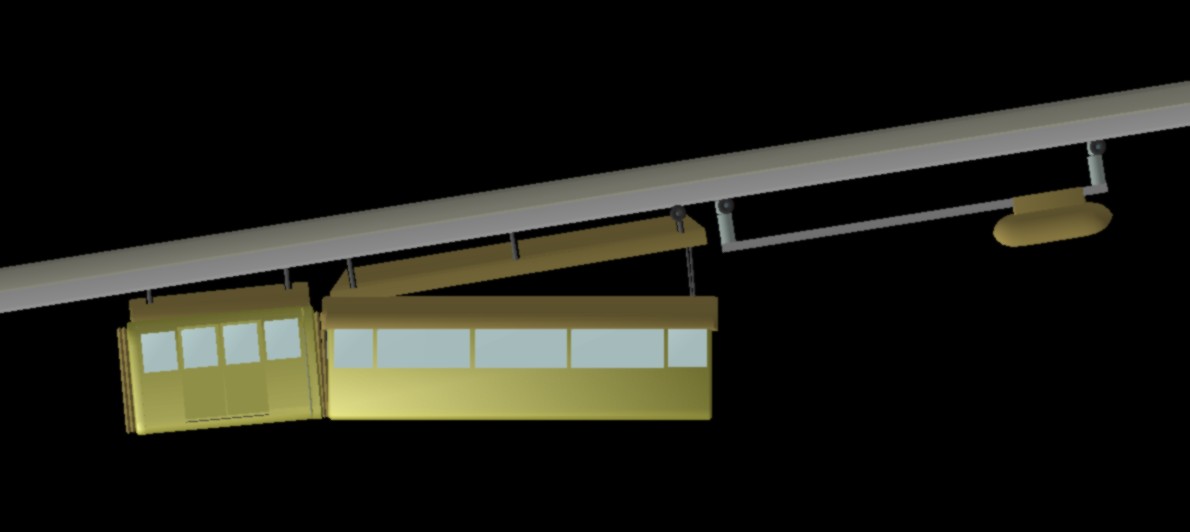

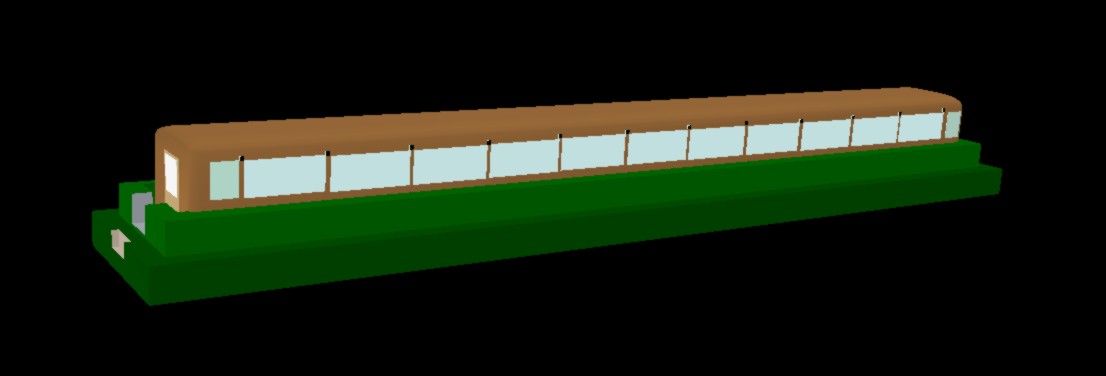

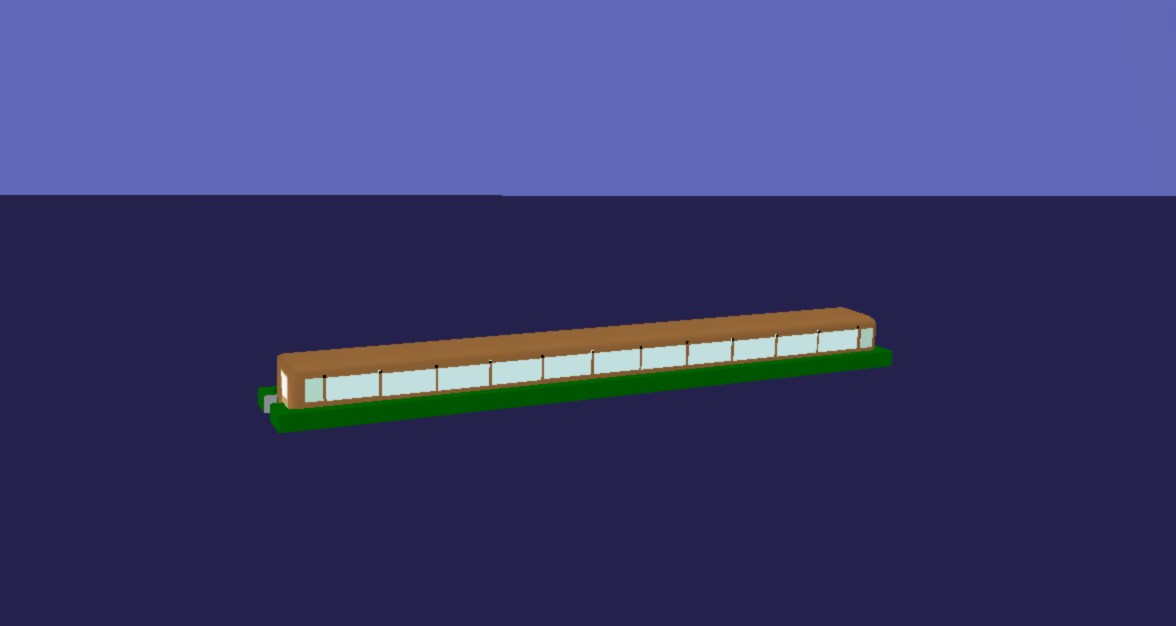

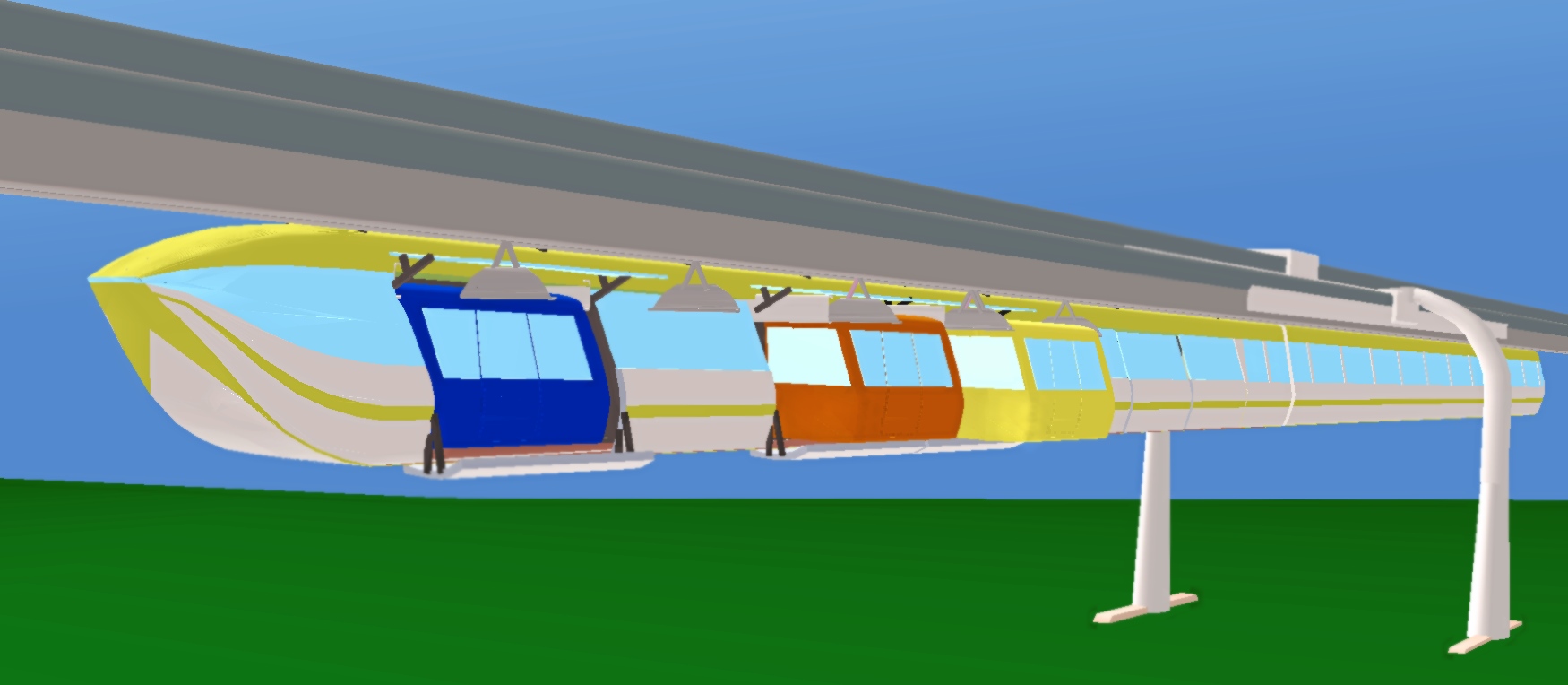

Local and

long-distance trains – both with an integrated elevator in the

front wagon. With this elevator, the doors leading to the cabins are

also used down on the ground. Passengers enter through the front door

(green) while those leaving use the back door. This efficiently will

largely compensate for the elevator delay.

Threshold ramps for

wheelchairs are pushed out under the doors.

These trains have hub

motors in all the wheels.

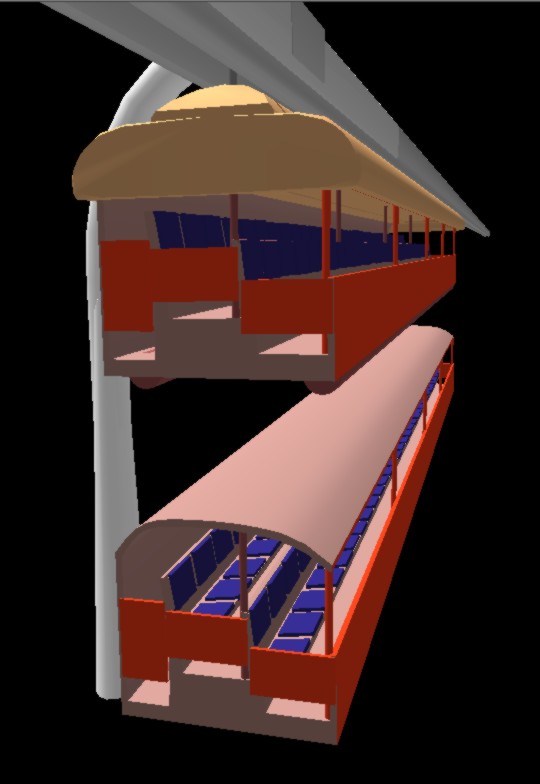

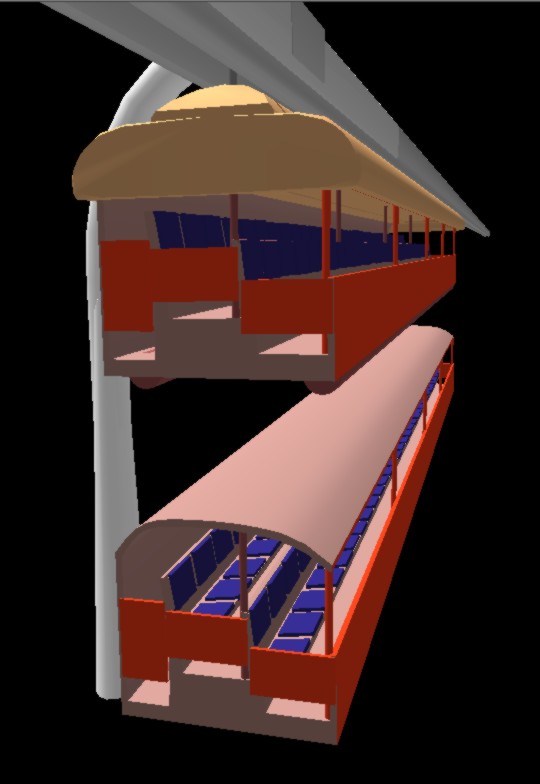

These

trains have exchangeable cabins (lowerable and raisable below those

funny hats), as well as a separate elevator module between the

wagons.

This elevator uses a side door, so that passengers can

enter directly if train and platform are on the same level. A

disadvantage with side door use is that any train penduling threatens

the passengers' feet.

A built-in threshold ramp might have been

used here, too.

The Center Wagon

This consists

essentially of three or four walls and a roof, as well as an elevator

filling the space between the walls. The elevator is for the yellow

train above depictet as hanging from a single cable coming out from

the middle of the ceiling, and the elevator movement should be guided

by vertical telescopic rails hanging from the ceiling, going down

through vertical ducts in the elevator walls. If there is a cable in

each of the telescopic rails (white trains depicted above), the

elevator may be lowered 15-20 meters for emergency evacuation, and

yet ascend again with properly collapsed rails.

If the elevator

has a side door, a conventional station flatform on the train's level

may be used, so that passengers can come and go quickly –

without elevator movements. The problem with this is that the

overweight-preventing sluice mechanism given by the elevator is lost.

A solution for this is to provide high traffic stations with an

antechamber (measuring the total passenger weight, and having

automatic doors) at each train door position. This antechamber will

then provide an alternative sluice mechanism. (The conductor may at

low traffic levels choose to leave the door open out there.)

With this external

sluice, the beamway will give as rapid passenger exchange on stations

as conventional trains do, and consequently as large transport

capacity if the latter were trying to give seating for everybody.

(But an elevator with entrance and exit on opposite sides might be

just as efficient.)

The thick back

wall of the center wagon should contain the elevator motor and an

emergency battery or generator capable of running the elevator for

emergency evacuation, and also be able to move a train somewhat in a

powerless area.

The central

element (regarding costs and operations) is the conductor, who sits

in the elevator.

The tasks of the

conductor are to:

check that the

passengers are ready to take the elevator to or from the train (–

and that they don't sneak past ticket vending machines), must pay

cash, or are walking towards the elevator

give the

passengers information regarding this strange system, including how

to pay and to get to the right destination

help disabled

passengers a little

take care of

parcels to be picked up at another stop. (Such flexibility is

natural in rural areas. This includes informing about who have been

observed.)

be a guard, and

at least warn and report troublemakers

deal with truck

drivers, construction workers and others with traffic-disturbing

activities

decide the speed

of the train if the conditions are too unusual for the automatic

control

The Propulsion

The train may have

a locomotive fore and/or aft. The advantage of this is that the train

weight can be distributed over a long distance. The picture shows a

locomotive with a large motor which can be displaced remotely. But

this will block passenger evacuation through end doors of trains

stuck in tunnels, under bridge spans, etc.. The most elegant solution

is to let an electric motor constitute the hub (and most) of each

wheel. This will optimize hill-climbing and acceleration, as all the

wheels will be pulling.

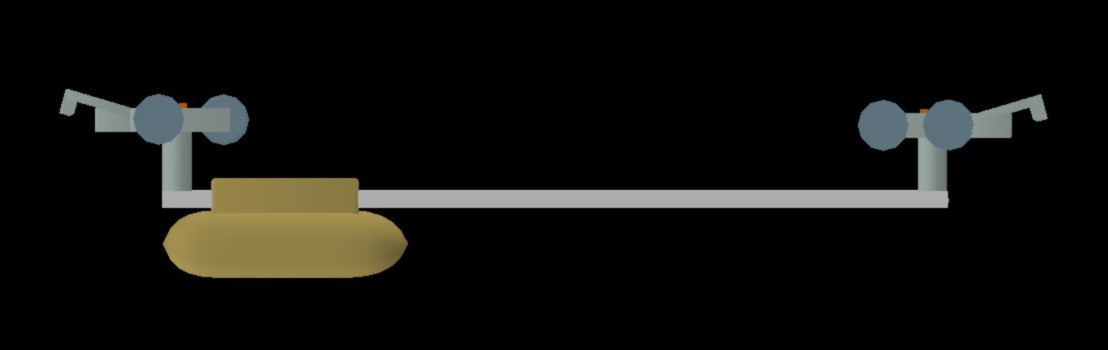

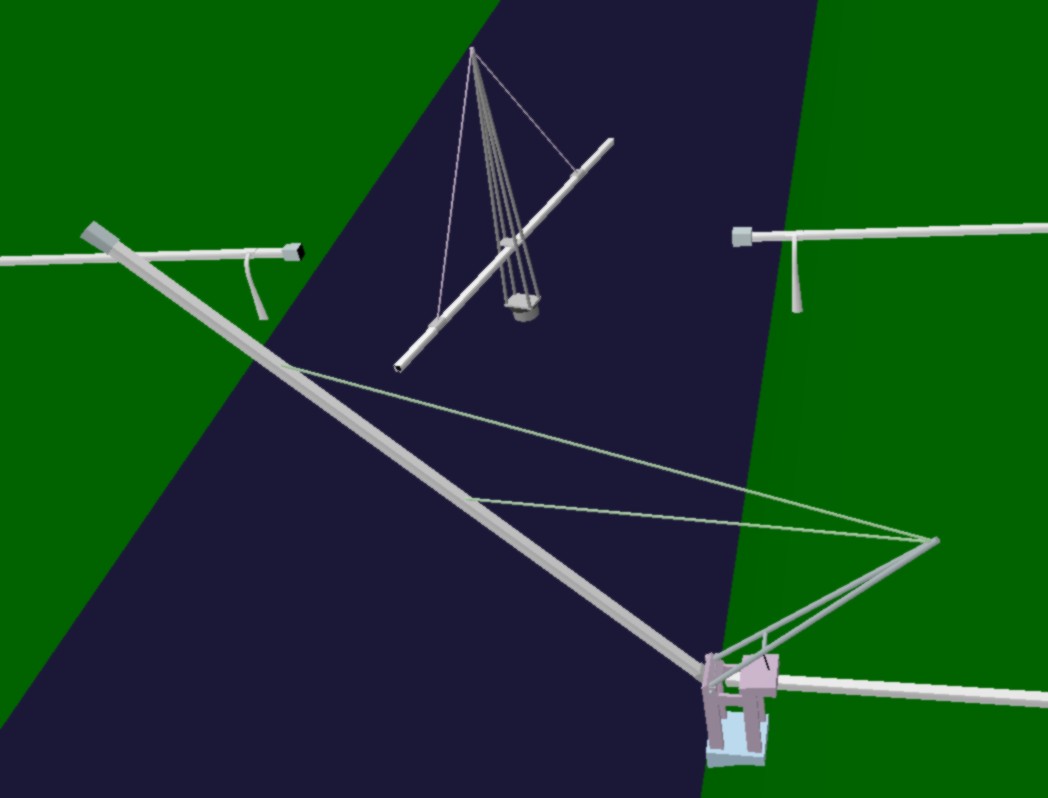

For high-speed

operation – no wheels, but the train slides on air cushions:

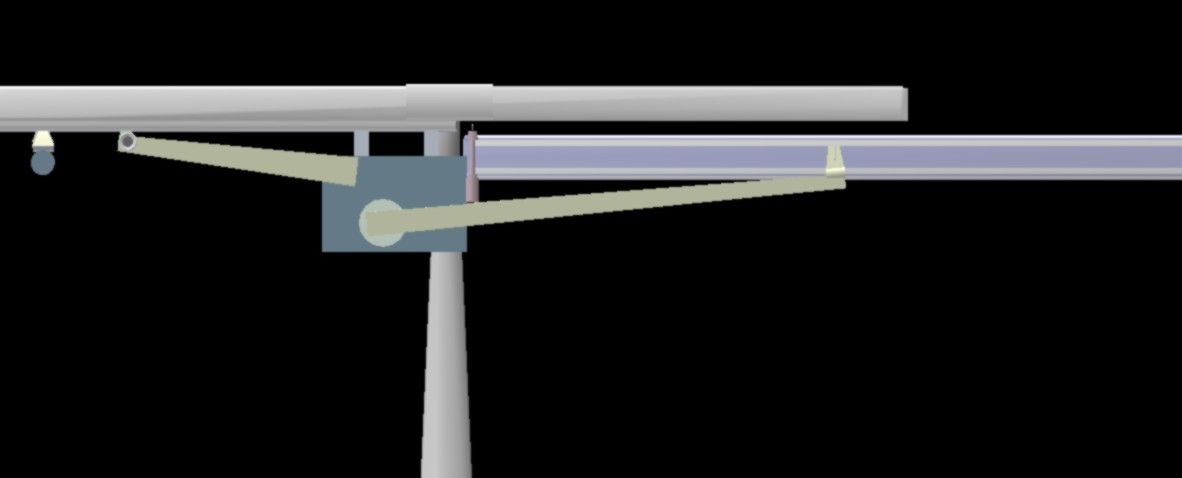

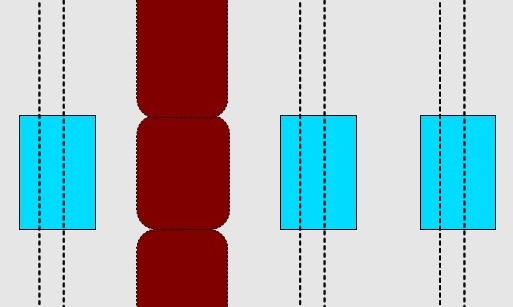

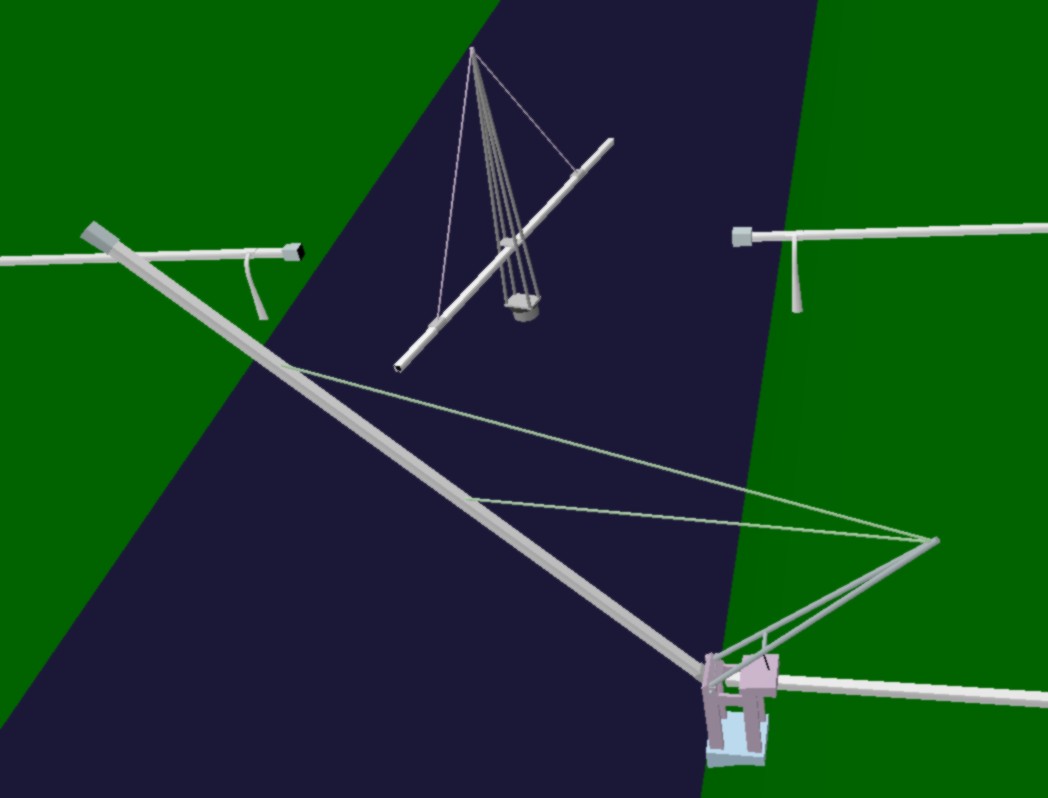

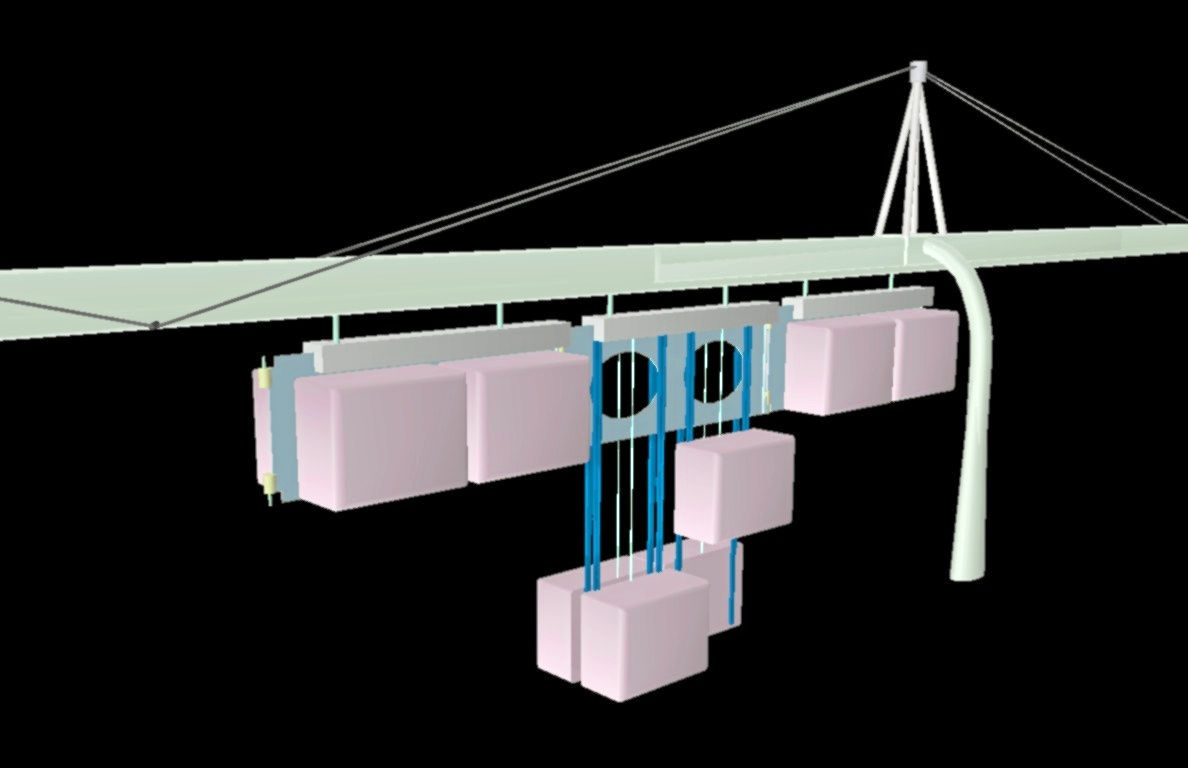

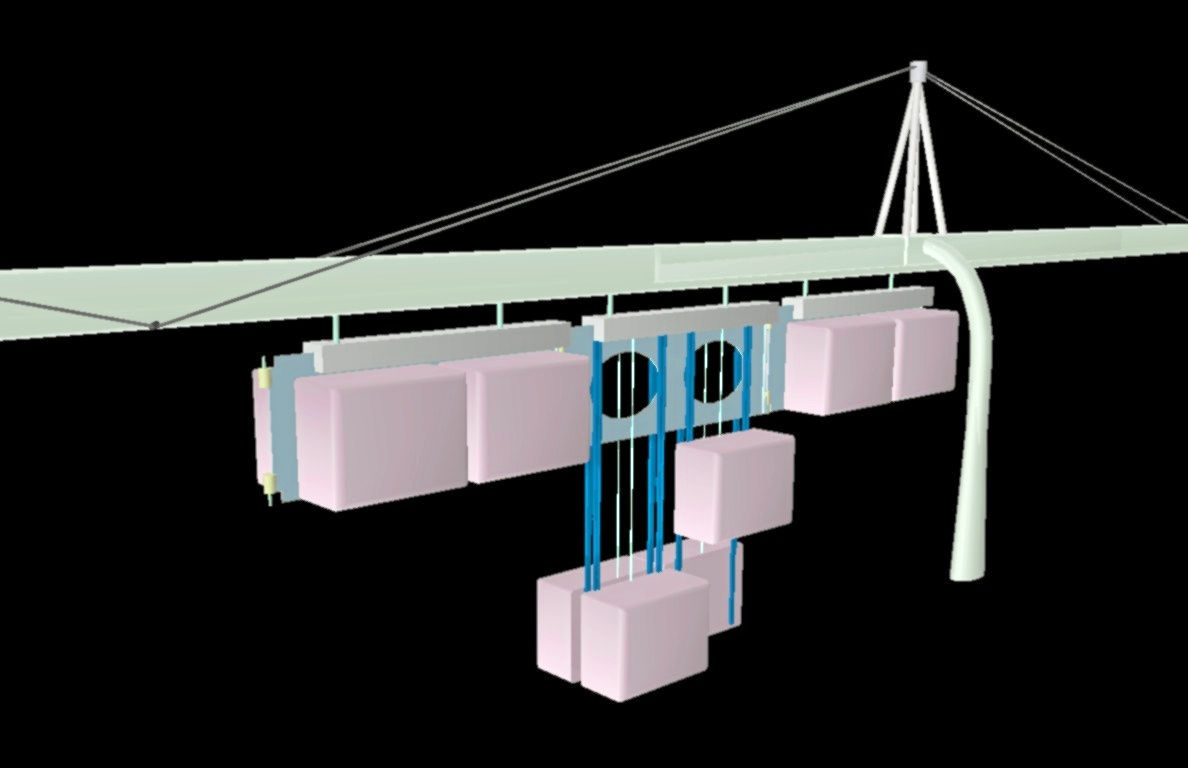

A

compressor “locomotive” (left), and one of the hovering

bogies with four air cushion units powered by high pressure air

coming through the tube.

The compressor hangs under two such

bogies.

Propulsion is obtained by opening valves backwards.

Several propulsion

technologies, using the same beam and mostly the same trains, are

available. The most important alternatives are:

Running on

wheels, with ordinary electric motors.

Like 1, but

airfoils near the wheels can lift partially, so that at least half

the weight can be relieved off the wheels.

Such air-surfing away

from vertical beam walls will keep the wheels in position in their

tracks. Wheels can thus be used at higher speeds.

Compressor-driven

air cushion surfing with high-pressure cushions above the beam track

and low-pressure cushions below the beam. This enables strong

resistance against penduling if the pressures can be reversed on the

side in danger of being lifted.

These may be

combined in various ways by combining bogies or bogie parts, and by

combining different elements on one bogie.

But one

combination – alternatives 1&3 – should be emphasized

as an optimal compromise, as it gives high speed on simple beamway

lines, that is lines not equipped with trainpulling equipment

(maglev, linear motors):

A combination

drive for quite high speeds – at least 200 km/h: Two wheels are

combined with three air cushions above the track and one (mostly

sucking) below. There are electric motors in the wheels.

The air cushions

above also act against the side walls, so that the wheels are not

stressed by forces from the sides.

This combination

is programmed so that the lifting force from the air cushions always

are kept so low that the wheels can give the traction needed (or

regenerative braking, which receives the braking energy). At high

speeds, the need for traction decreases, even though the power level

(i kilowatts or horsepowers) is high. As the wheel stresses are

reduced – by perhaps 80-90 % – wheel traction can be used

at much higher speeds – probably well above 200 km/h.

The wheels give

speed control. This means the train stands completely still during

stops in wind or in a hill, something likely to cause problems in

connection with air cushion drive.

Stabilization

against pendulation implies: Fast-acting valves reverse the air

cushion pressures on the side about to be lifted by a wind gust.

Simple, strong

wheels of steel or compact rubber can now be used without the

disturbing vibration forces. (The wheels are not to transmit forces

for emergency braking. This is done by mechanisms pinching the edge

of the beam.)

The compressor

creating the air cushions hang below, at the wagon suspension rod.

There may be one unilateral combination of wheels + air cushions (for

the left or the right side) for each wagon suspension, but perhaps

rather a bilateral combination, so that pendulation can be controlled

at each suspension.

Every suspension,

with its mechanisms, will then become a complete propulsion module,

an exchangeable microlocomotive which could have run alone, so that

the wagon only need small motors for displacing the suspensions

sideways.

These prospects

are more thorougly discussed elsewhere, but it should be said that

those who work with developing such technologies for ordinary trains

(running on the ground) should envy the beamway's conditions: well

balanced lightweight trains at a large, clean steel surface, above

the snow and sand of the ground level. Those now developing hover

transport (with magnetism or air cushions) and without a need of

handling heavy transport, err seriously when they take heavy rail as

the point of departure. It may seem natural to vary one factor at a

time, but a dual innovation is now needed: both suspended rail and

hovering.

Traffic Routines

The control system

can control access for the (not unusually audacious) passengers, and

can refuse to transport passengers up if the elevator or train is

getting overloaded. It can also detect obstacles and stop for them.

For local transport, unmanned operation may be feasible. Every second

departure, for instance, could be unmanned – for subscribers

who feel secure with the system.

As the beamway

system simulates scheduled buses instead of a stream of private cars

(the FLYWAY attitude), side beams (for passing a stopped train) will

not often be needed. The standard operating mode could be that two

trains start together. The first one is a direct train with few

stops, and the second one stops at many places. When the direct train

is about to overtake the other, the two can swap roles at the next

end loop passage.

A train's two

passenger wagons could be assigned to two branches of the line. When

the train comes to where the line splits up, one wagon can be

delivered to another train on one branch, while the center wagon with

the other passenger wagon continues on the other branch. If the lone

wagon has a motorized bogie, it should be able to run on its own for

a while as long as no stopping is required.

Many Kinds of

Stops

A beam train with

elevator could take passengers on and off almost anywhere, and in

special cases like ambulance transport (perhaps to a side track into

a hospital) this flexibility may be useful. But for practical

reasons, designated stops will probably be chosen – at least on

crowded places. The elevator will of cause detect people if it

approaches them from above, so it should be less dangerous than the

tram so commonly seen in pedestrian precincts. A simple and practical

solution could be to let the elevator go down towards a lawn, a

flowerbed or a lawn, while the passengers go up on a 30-50 cm high

ramp which will divert the stream of passers-by. If the elevator can

push out a foot board, wheelchairs can roll right in.

The train should

be able to start running while the elevator is going up ( – and

the elevator shoud have a few folding seats). Conversely, the

elevator might start descending while the train is slowing down at a

stop, but that may be to demand too much discipline from the

passengers. Some seconds will be lost if the elevator descends while

the train is standing still, but this is little compared to the

delays a bus suffers while its driver sells tickets.

The beamway could

visit many unusual places: the deck of a boat, a stadium stand, the

gate corridor of an airport, or the balcony of a closed-off area.

Some kinds of stops may be used only during special arrangements, and

then tickets may be sold or checked on the train. Ticket holders

could be admitted to one cabin, while ordinary travelers use the

other, so this will be closed when the train stops at the site of the

event. On an airport train, the cabins may be assigned to domestic

and international travelers, or for checked-in and not checked-in..

A City

Beamway

The

beamway doesn't displace other forms of traffic, and should be so

cheap to build that also smaller cities and towns can afford to think

line networks and branching lines instead of just one or two lines.

No

matter how congested the ground traffic is, the regularity and

reliability of the beamway will not be affected.

The

beamway can easily be built with a loop through a destination suburb,

even if the streets and buildings are old, so it will not lead to

dense spots of built-up area like a conventional metro does. I must

say it is appalling to see how local politicians assume suburbs will

concentrate around metro stops. This metro is then a Procrustean

line.

Correspondingly,

the city area should have an end loop which covers the most important

destinations in the central area. Having to regard the city center as

a point, is a sign of failure.

It can be a

dilemma for the city planners to choose: Should we have a small

central ring which becomes a suitably diffuse end stop, or a large

central ring which in itself becomes a useful ring line? It may be of

interest to have both. The two rings needn't be very different if

they are both single-tracked, running in opposite directions.

A beamway line's

poles may be freely standing racks, and then the line will be

reconfigurable, e.g. for a temporary line. Nice to have during events

like olympic games.

Metros and

Architecture

Metros (subways,

undergrounds...) are characteristic of large cities, and they are

difficult to scale down for light traffic. If we consider the space

requirements of a metro station, one major cause of this becomes

evident. A station for four tracks, each 2.5 meters wide, might need

2 meter wide platforms on each side of a track, plus 2 meters for a

stairway and elevator for each single or double platform. The minimum

station hall width will then be 10 meters for 4 tracks + 16 meters

for 8 platforms + 10 meters for 5 stairways = 36 meters –

multiplied by perhaps 30 meters for giving access to a few wagons.

This amounts to over 1000 square meters, and in addition comes a

crossing corridor above or below.

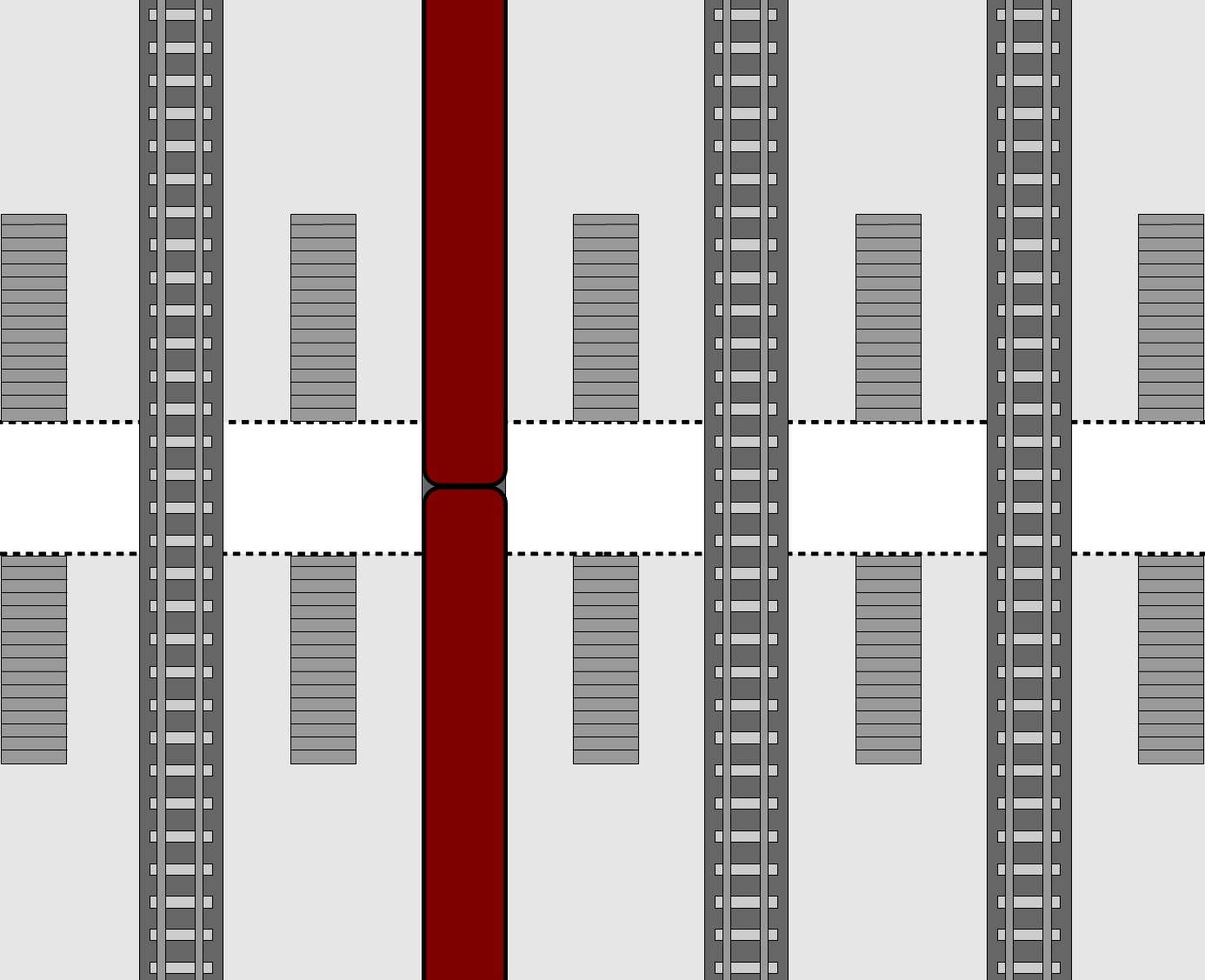

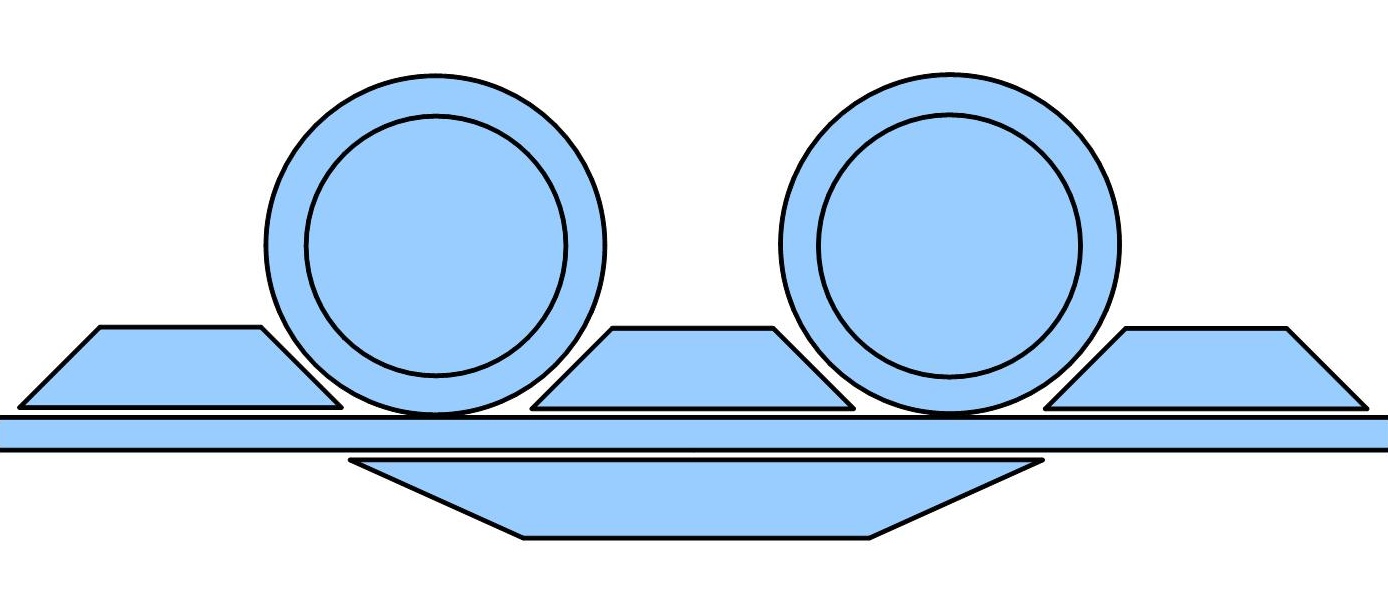

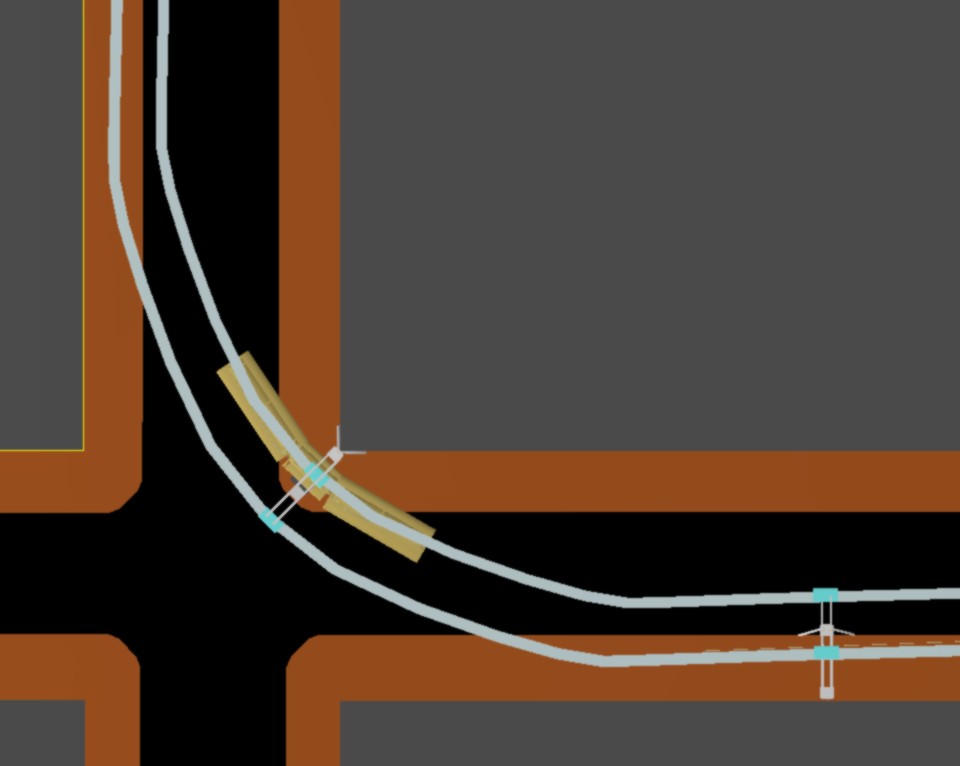

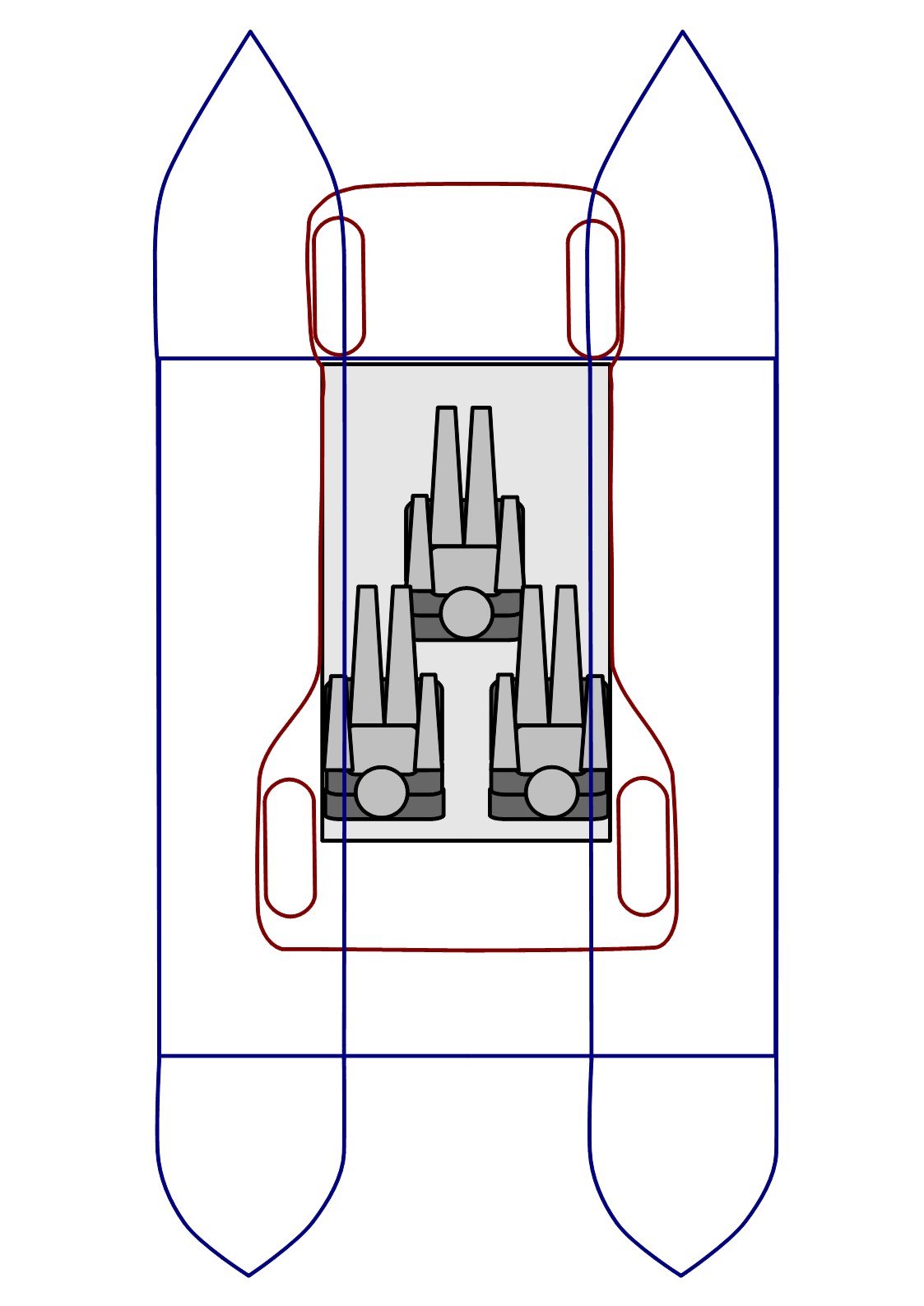

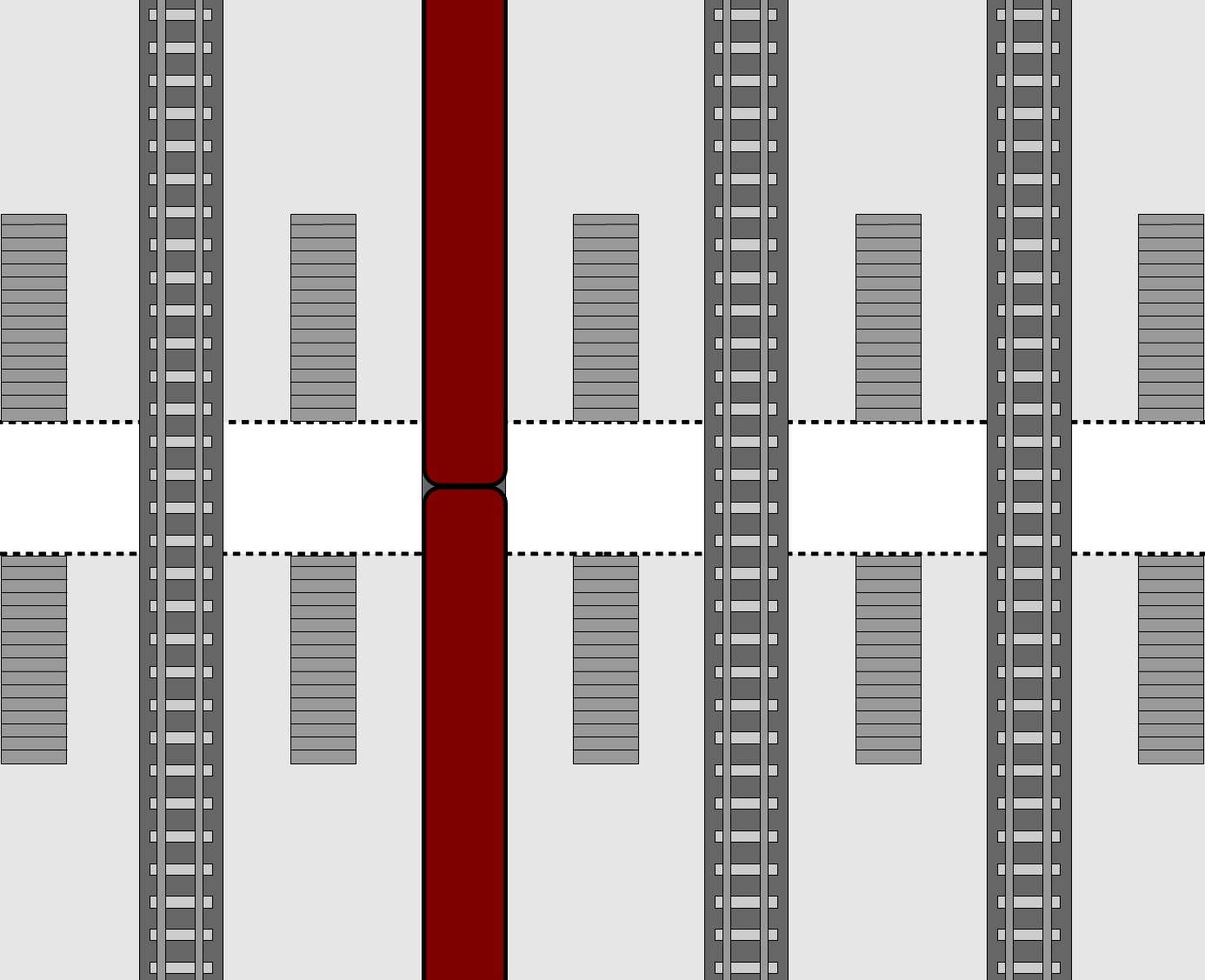

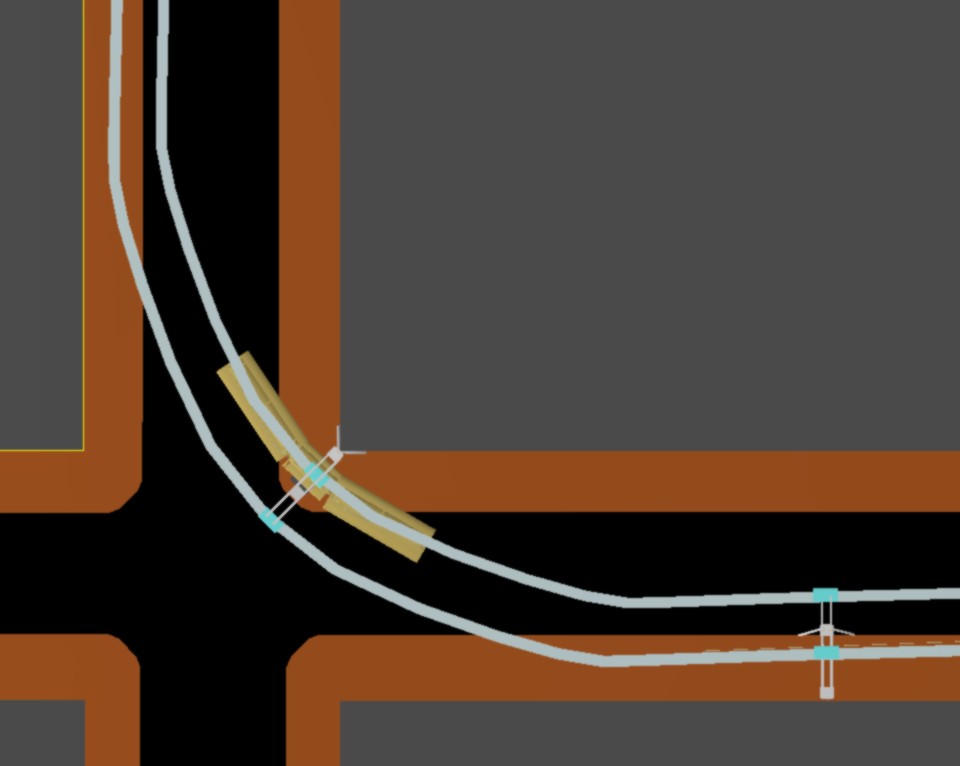

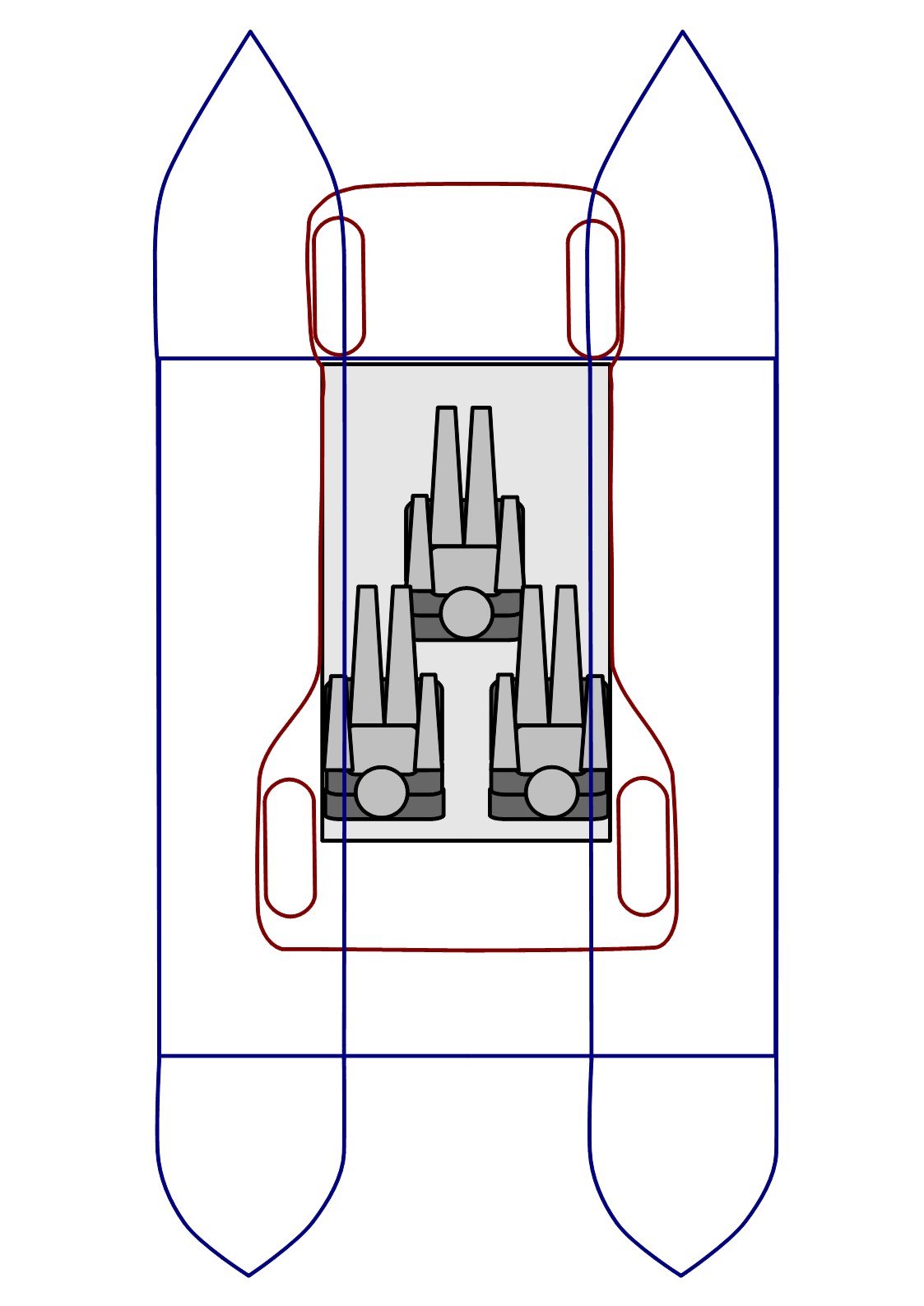

A

conventional station for four tracks, with one train present.

White:

A crossing corridor below or above.

A pair of stairs can have one

escalator and one ordinary flight of stairs. Besides, an elevator

will probably be required for each platform. It can be situated

between the stairs and make the corridor awkwardly narrow, or it can

be beside a flight of stairs and increase the station width by five

elevator widths.

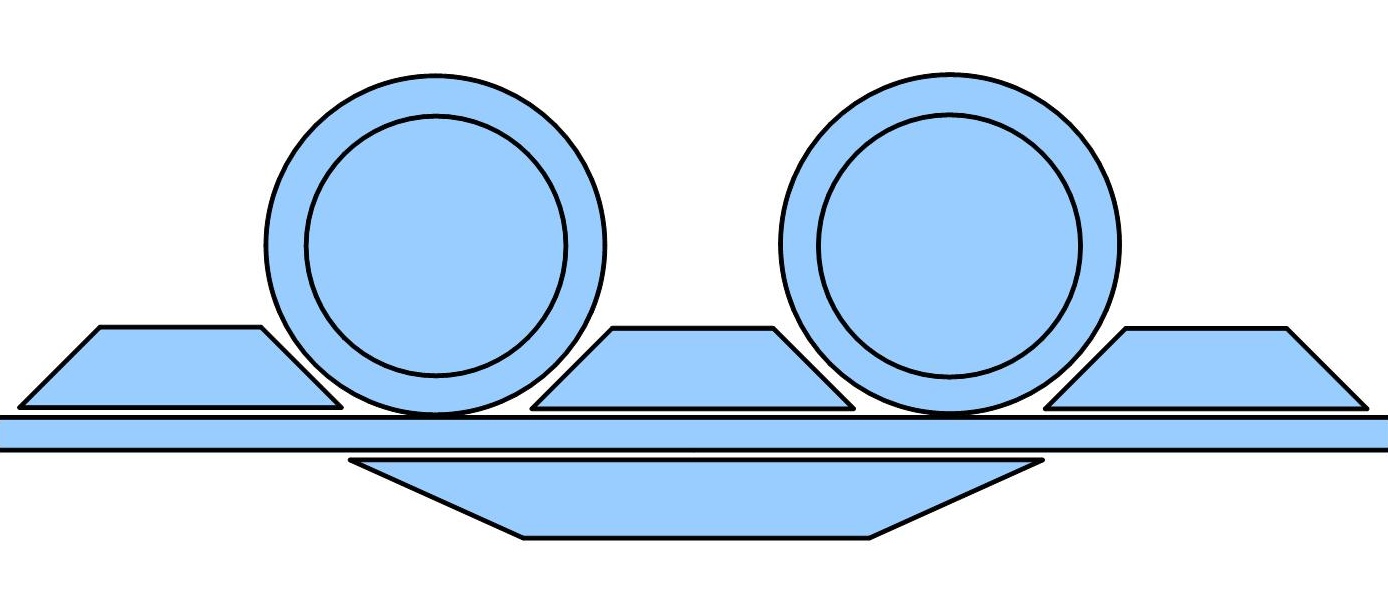

A

corresponding station for beamway trains having elevators.

The

blue rectangles are ponds reserving the areas for train

elevators.

The part of the hall in the upper part of the picture

is for departing passengers, the lower part for arriving.

If beamways were

used instead, stairways, escalators and elevators were not needed in

stations. With 3-3.5 meters of width reserved for each track, and 1-2

meters extra on each side, the hall might be only 13-18 meters wide.

With only 3 meters of the train length coming down in the hall, a

room as short as 8-10 meters could be used. So the beamway station

needs only about 15% of the normally required station area. And it

might be a few floors up in a building. (The trains would take 3-4

meters extra hall height, but this is only empty volume, without

construction complexity.) Besides, much space is saved in the

environment due to the short transition between parallel tracks and

multilevel, strongly curved tracks spreading in the environment.

Actually, the

space savings would be still greater if two lines crossed at a 90º

angle in the station area – in the same plane, but with trains

scheduled not to meet. The passengers would then only experience

that the doors were slightly displaced. Also conventional trains

could have stations at such a crossing, but this would result in

platform islets hardly permitting more than one train door to be

used. Hence the complex multi-level design of conventional stations

having crossing lines.

If beamway trains

were to cross in separate planes, the upper one would need a 6 meter

high elevator or a one meter high platform with ramps.

Every 2x3 meter

large elevator could go down to an equally large depression in the

floor, containing something like round rocks, flowers or shallow

water. If the elevator door leading to the front wagon were used as

entrance, and the door leading to the rear wagon were used as exit,

the passenger exchange would be so rapid that most of the time spent

on elevator movements would be regained. (In such a hall, the trains

could go just 2.5 meters above the floor.)

Such an elevator

might take 20 persons, so if more should want to enter or exit at

once, the small scale nature of such transport would become evident.

But the savings in space and other resources would be dramatic, while

the lacking capacity would be more moderate. And capacity can be

increased in various ways: The automatization potentials of the

beamway can e.g. make higher departure frequencies feasible. The

automatization potentials are related to the increased safety, as

people are unable to enter tunnels and tracks.

As long as the

trains go only in tunnels, the beam can be mounted in a very robust

manner, and the occurrence of many standing passengers is ok. The

sluice function of the elevator will then not be needed, so people

may also enter trains through simple stairways standing between the

trains.

Concentration of

the passenger stream in a few elevators permits use of conductors –

for improved service and security, as well as new operational

possibilities, such as sale or control of tickets to events to which

the train may go.

Beamway tunnels

can easily also be used for other traffic or transport if the

diameter is sufficiently large. Such combination use becomes more

difficult if conventional rail is used.

A beamway station

can be a few floors up in a building. As this railway type goes in

the upper floor above ground activities, architects and community

planners should operate with an expanded floor thinking, including

not only rooms, but also traffic and nature.

The old paradigm

was: All ground traffic had to be in one plane – shoehorned and

axed. The new paradigm is: The light traffic components should float

up to the surface – in the upper floor – where they, as a

beamway system, can be organized with a superior efficiency and

safety. Also natural activities, with pedestrians and animals, fit

into this multi-floor structure. Perhaps not so much under buildings,

which block much light, but at least under beamways.

Future planners

and architects will find it natural to plan non-blocking railway

lines through buildings, combined with small station rooms near

sidewalks, as well as in airports, hospitals, stadiums, etc.

Scalability

A

rail system should be scalable,

so that it can be used both in low traffic areas and high traffic

areas. It is common that rail systems (especially monorails) are

designed for large cities, and consequently get bad scalability. The

present beamway system is well suited for sparsely populated areas

(it scales down), mainly due to the built-in elevator, which

eliminates the need for station buildings. And even for quite high

speeds, the track needn't supply pulling force. This gives good

scalability, as it is easy to scale up by using a double-track line

and short departure intervals.

Beamways use

little energy and low power supply voltages. At about 1000 volts,

standard electronic components can be used, and hub motors are now

being mass produced for cars.

If trains become

cheap, backup trains may be kept ready at various places. And beamway

conductors (local housewives on part-time assignments?) will be far

easier to find than skilled train drivers.

Where can the

Beamway go?

In city

streets:

Far greater radius of curvature (and absence of

obstacles) enable far higher speed

It is simplest to

let the beamway follow a road – at least as long as this isn't

crossed by bridges. If the road goes in a tunnel, the train can go

slightly above the road and behave like a bus, but the beam will

demand an extra meter tunnel height in order not to be in the way for

high vehicles. It shouldn't be too difficult to cut a groove for the

beam in the tunnel roof. Having this beam in a road tunnel, has

important safety potentionals: Remotely controlled beamway vehicles

(with backup batteries) can be used for firefighting, rescuing

people, or pulling out cars.

It may be found

advantageous to give the beamway its own tunnel immediately beside

the road tunnel, as this could also serve as an emergency exit for

the road tunnel, and a beamway tunnel will be much simpler and

cheaper than a road tunnel. It may in such situations be smart to let

the beam near the tunnel area be carried by freely standing racks

which can easily be moved to the new route.

The self-extending

beamway described above – lifting half-beam after half-beam

into position – can also save time and money during tunnel

construction. A tunnelling machine will then go in front and excavate

a round hole with a diameter < 4 meters. In the rear, the beamway

will be built by mounting half-beams each time a gap is created

behind the steadily advancing machine. Immediately behind the

tunnelling machine, a special slurry material remover will transfer

the excavated masses to wagons moving it to e.g. a bay crossed by the

beamway.

The beamway has no

need for its own bridges like conventional railways do: The beam can

be retrofitted on an ordinary road bridge.

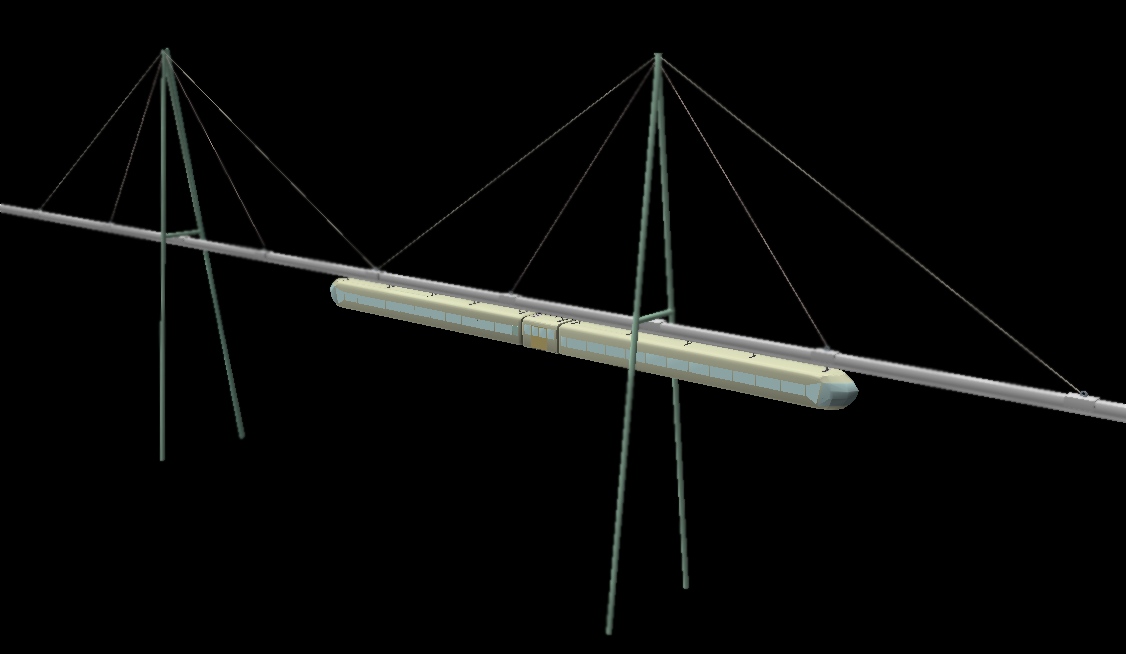

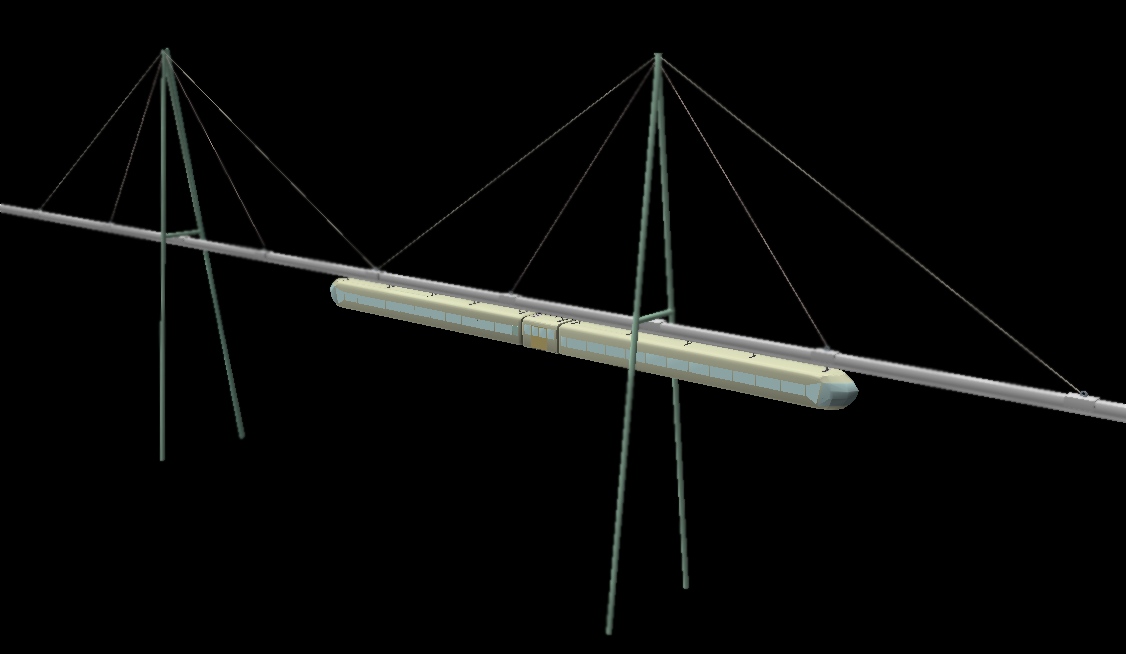

If the beamway

is to get its own bridge, it can be just a beam under a simple cable

span. The poles are now replaced by suspended beam-holding

brackets.

Perhaps the tower-building merely implies erecting

standard steel profiles?

- And building a bridge simply implies

hoisting up something assembled down on the ground/barges?

These bridge

types can be opened

More (shorter)

turnable bridges

Agriculture

– particularly energy crops:

Harvesters and other machinery

can cover the fields by moving like beamway trains on beams which can

move sideways on a very wide “conventional” railway

track.

Containers go out with the crop and in with fertilizers on

the external line in the bottom of the picture. (More about this

here.)

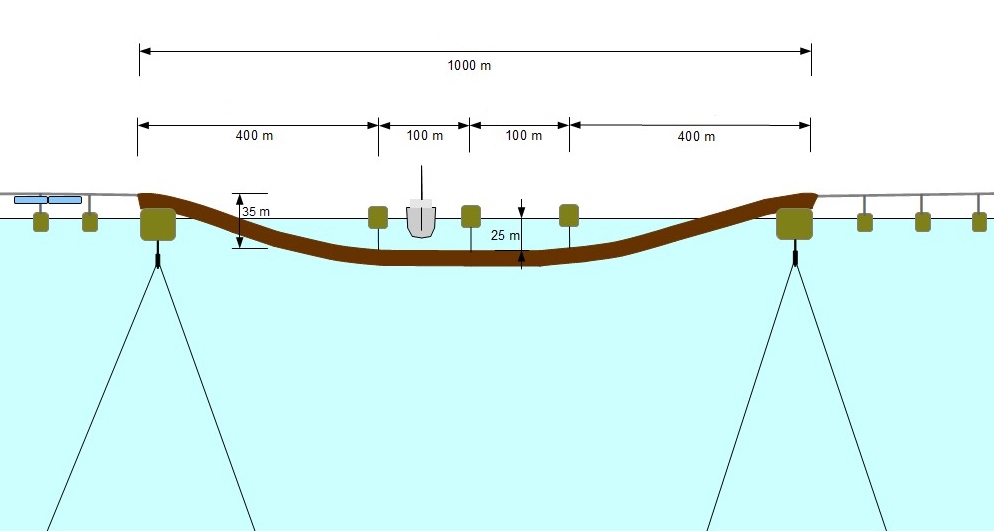

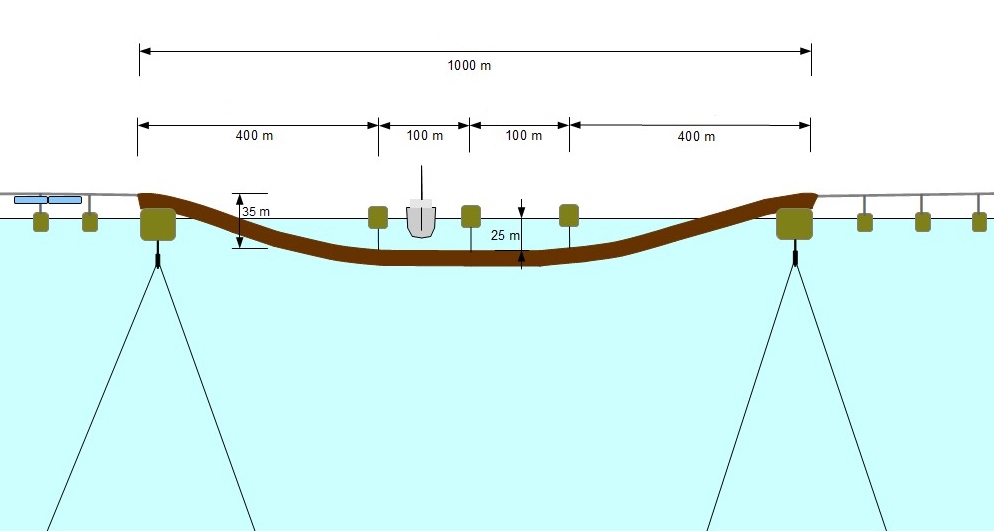

A submerged

floating tunnel like this is 1 km long, perhaps 4 meters thick, and

can be towed out from a shipbuilding yard. A pontoon-held beam can be

used for the rest of the crossing.

The submerged floating tunnel

has two full depth ship lanes. Small boats can cross almost anywhere.

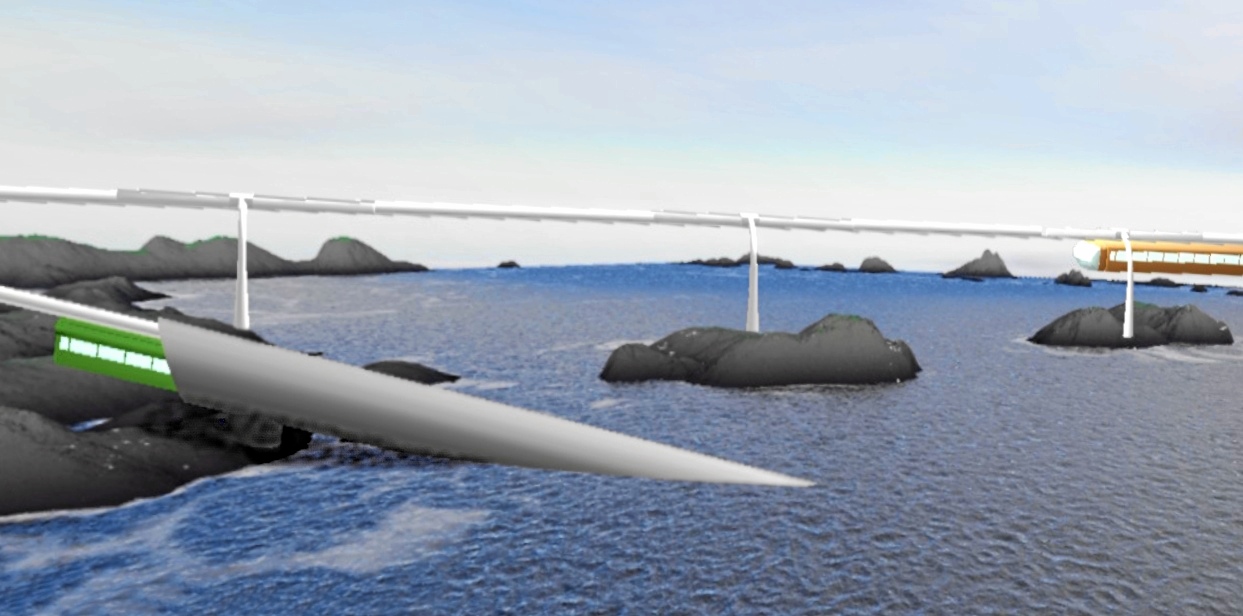

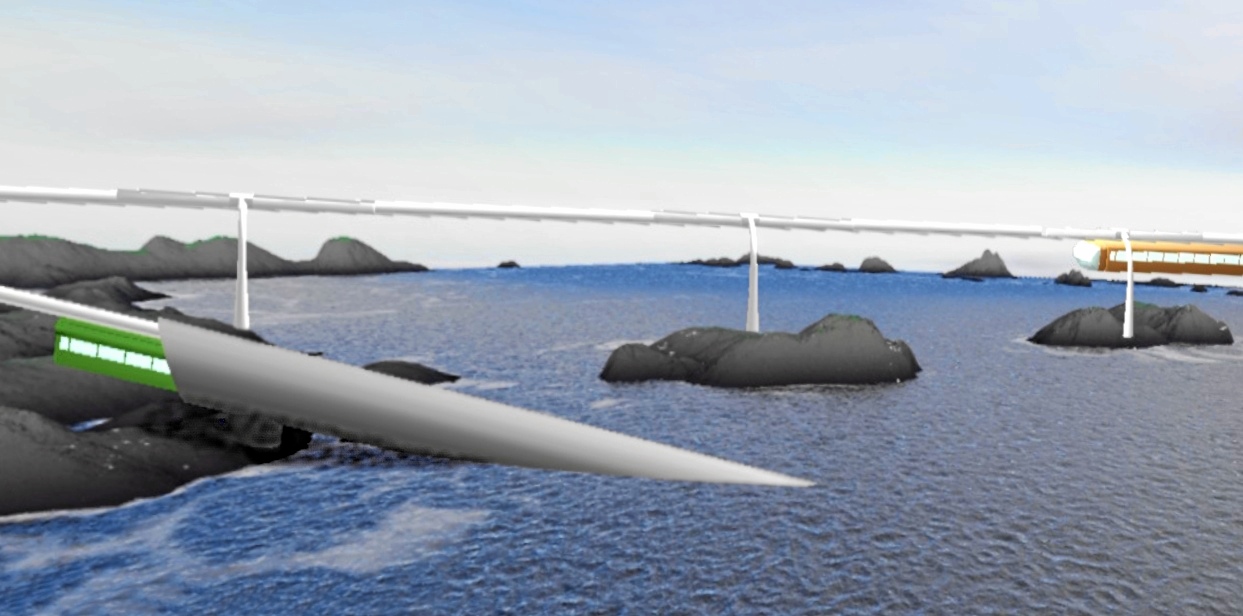

The beamway

can jump from rock to rock – also submerged ones.

The green

train is using a submerged floating tunnel.

If it isn't going

to cross ship traffic, it can go on a quite simple pontoon chain. If

it is to cross a wider channel or bay, it may use a submerged

floating tunnel, which (like the pontoon chain) becomes far simpler

and cheaper than a similar for cars or conventional railway. (See the

previous picture.)

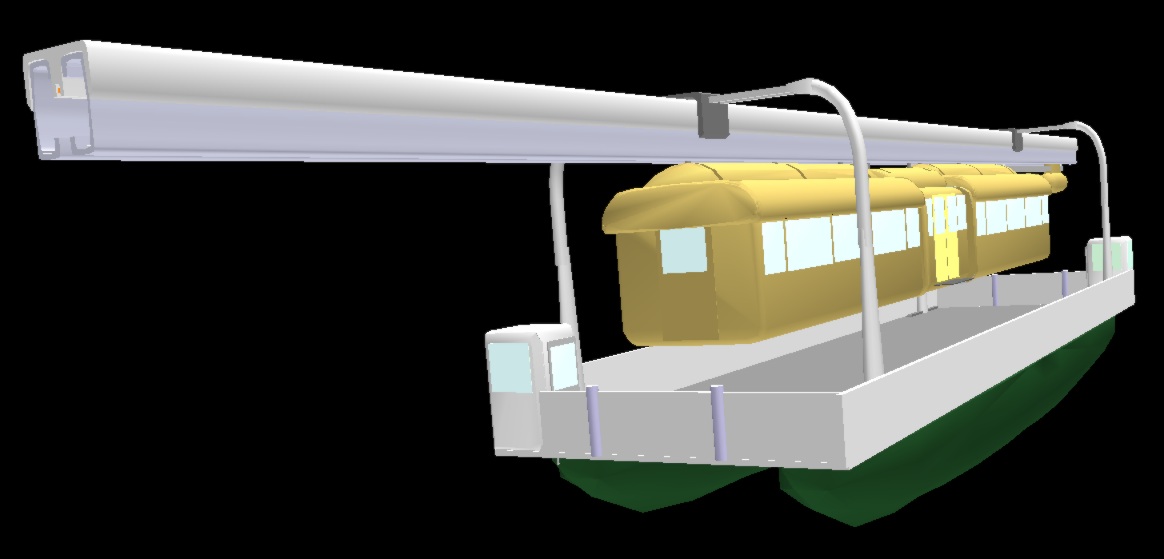

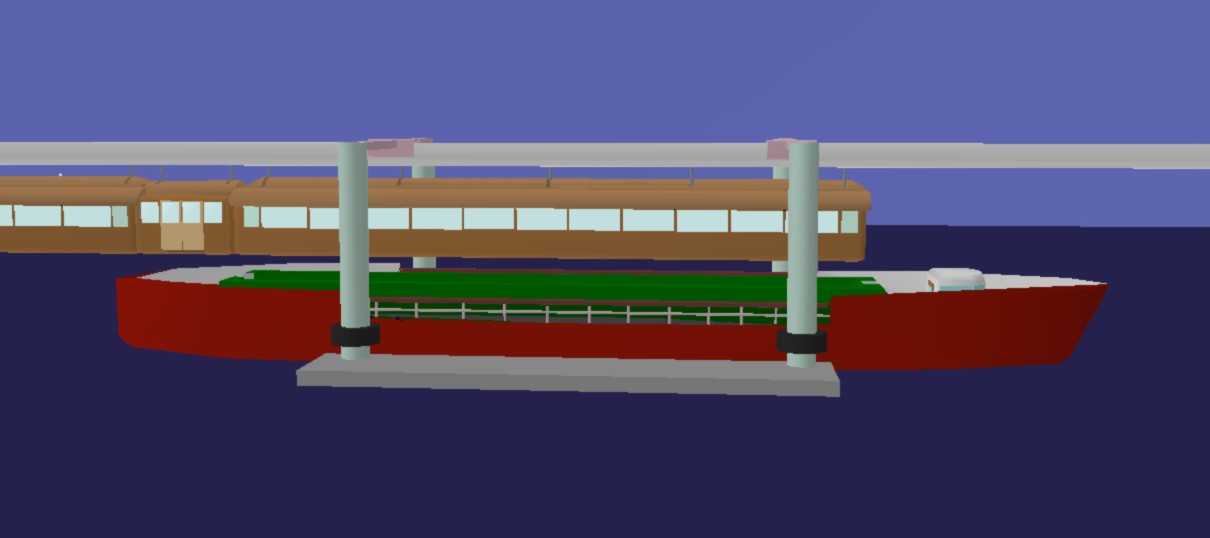

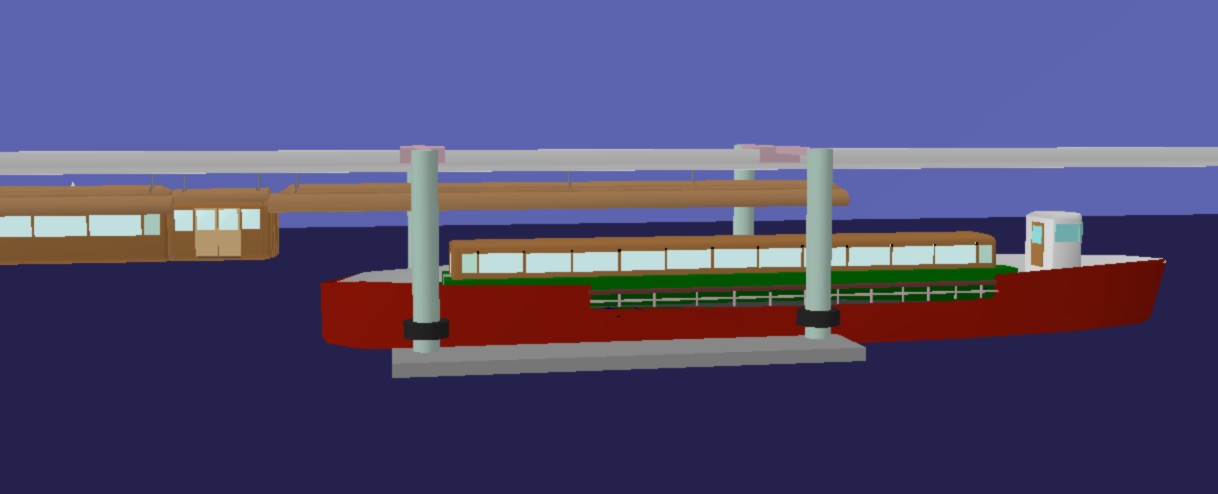

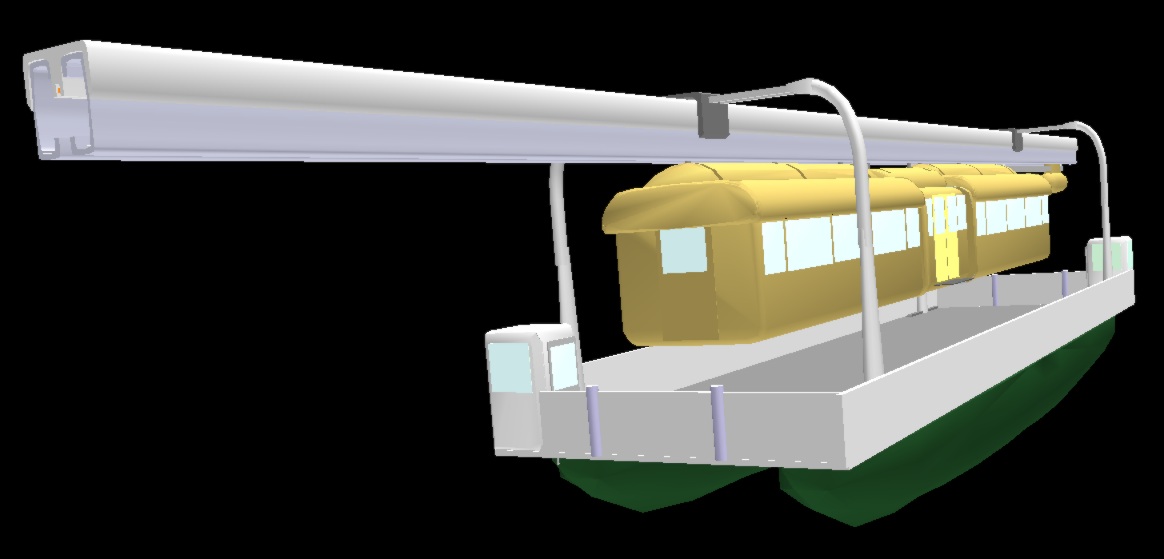

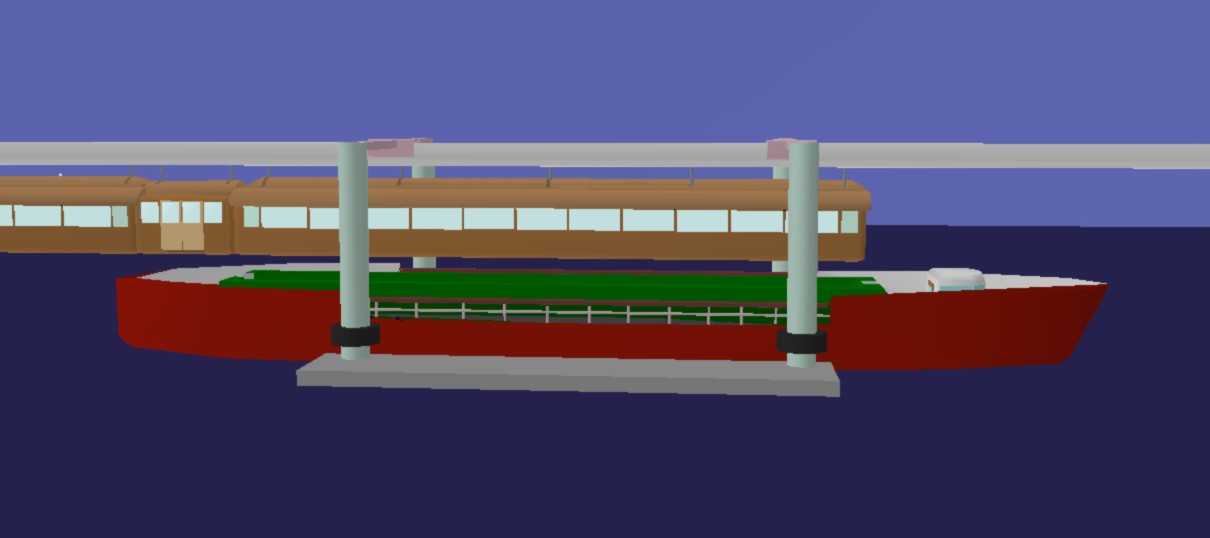

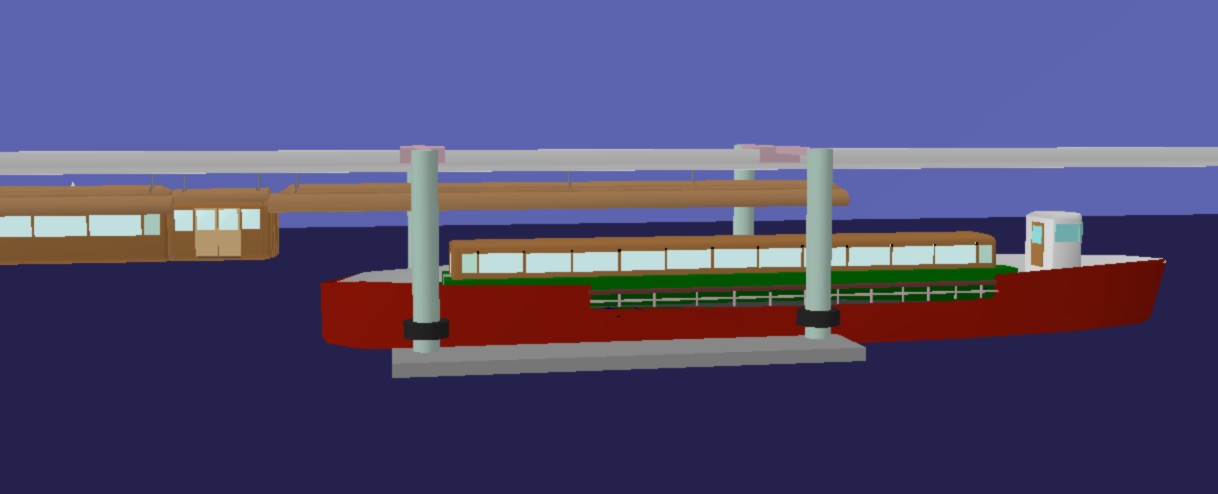

A

catamaran ferry for short trains. The receiving beam has a movable

end – for obtaining connection with the ferry's beam.

Also

electrical connection is obtained, so that the ferry can run on

rechargeable batteries.

The beamway

can easily do hill climbing by pinching the beam with powered wheels

– both from above and below

The hill climbing

capability means the submerged floating tunnel can use a quite steep

tube (best sheltered if going down in a bay).

The

train takes the elevator up to the mountain plateau

Annoying

Penduling?

Will the

passengers be annoyed by train penduling due to crosswinds and

entering/exiting turns?

The proposed train

type can displace its suspension sideways. The wind may then simply

be permitted to displace the train sideways. The off-center

suspension will then by gravity counteract a tilt. This will not deal

with wind gusts, but the following mechanisms will.

The

wagon suspension can resist penduling up to the point where wheels

are almost lifted on one side, and this will give considerable

stabilization. (Centrifugal forces in turns will of course not be

counteracted in this way, as the turns have banking – tilted

beam – and an orderly train banking/sideswing will be

permitted.) Compressor-driven air cushion trains will be more able to

resist such swings, as the air cushions about to be lifted up can

adhere to the beam by suction, by reversing the pressure to an

underpressure. And a still firmer tracking can be obtained by having

air cushion units (normally

sucking) or wheels also at the bottom side of the beam.

At higher speeds,

the train can be stabilized wagons

by means of a set of stabilizers on the bottom – like anal fish

fins, but at least five side by side. The outer ones should be able

to detect side wind gusts, and the whole set should then be rotated

sideways to displace the bottom of the train towards the wind.

The beamway can

also increase the stability by using side support wheels. These can

be mounted on the lower edge of the wagons, and enable support from

side support rails installed on problematic line stretches (and

omitted elsewhere). The side support utilizes the ability of the

train suspension to shift the train to the side.

The train is

here shifted towards the support rail, which will then push

horizontally.

(Fine for air cushion units able to both blow and

suck this support rail, so that the train need not be shifted

sideways.)

The train is

here shifted out from the support rail, which will then carry some of

the train's weight.

(Not so good when snow can fall on the support

rail.)

The T-shaped

support brackets connecting all the rails/beams will strengthen the

whole beamway and make greater pole separation possible.

Too strong winds

should not result in a sefety problem, as the train will merely yield

and swing to the side. This will merely result in passenger annoyance

– like during a turbulent flight. In strong side winds, the

beamway will be far safer than a bus. On windy stretches, the beamway

might get a tunnel.

The Safety

The conventional

railway is very sensitive to rail disturbances. It doesn't take much

of an avalanche or (mud/rock) slide to cause derailing. Even a quite

modest water flooding can wash away the ground support under the rail

track.

Under the beamway,

however, quite large avalanches/slides can pass without disturbing.

In risky parts of the line, the beam will be carried by racks having

one leg higher in the slope, and one leg lower. Both legs will be

streamlined in the cross-direction, and then it probably takes a real

rock slide to damage the track. (Wires going up a mountainside may be

used for extra safety.) If one rack collapses, the beam will bend

downwards and probably give a scary train passage near the ground.

(On such dangerous places, a staggered beamway configuration will

probably be used, with each C-shaped steel beam having its splice

near the middle of the other one.)

Driving heavy

trains is inherently a gamble – particularly through

wilderness. The train driver cannot know if the track is blocked or

damaged, and if such a situation is encountered, the train is unable

to stop in time. One then simply hopes that the train is able to

sweep away the obstacles. This assumption may be acceptable in flat

and simple terrain, but not with fast trains through wilderness.

By having an

embedded power line, the beamway avoids the problems and dangers

plaguing the conventional overhead wire system. A full beam

disruption will cause an easily detectable power line disruption.

Smaller beam disturbances should be detectable by checking

transmission of light, microwave or ultrasound signals through the

beam interior.

Collision with

other traffic or with animals are naturally rather unlikely. A quite

simple radar (and/or a tiny precursor vehicle) can easily detect

obstacles ahead the train, which then brakes automatically. And a

beamway train, which can emergency brake by pinching edges of the

beam steel, can have a very short brake distance.

In tunnels, there

will not be meters for traffic below, but half a meter may be

granted, so that people or animals straying in there may be passed,

perhaps toppled over, but not maimed.

In a tunnel or

submerged floating tunnel, a (quite derail-proof) beamway train is

unlikely to crash so thoroughly that another train is unable to pull

or push it out. The train's (hillclimbing) traction can also pull the

train out of a partially water-filled tunnel. Backup batteries in the

center wagon will be useful if the power rail is short-circuited. The

train's computer can easily be programmed for pulling the train out

of water – even if this involves filling the train partially

with water. Such an escape is feasible because the train will quite

certainly be alone down there – not in a chaos of helpless

vehicles. The terror threat will be far weaker when such emergency

procedures are known to exist.

If a suspended

train accidentally gets stuck, it can be necessary and problematic to

get the passengers down. A backup battery operated elevator in the

train will then be very useful. It is also useful to have

downhoistable passenger cabins. Both mechanisms should have extra

wire for emergency situations. If the ground is too far away, another

train can come to rescue and pull or push the stranded train, or

receive its passengers. Trains should therefore have doors in both

ends.

The safety can be

transferred to other traffic. Cars can be transported more safely

through a submerged floating tunnel by means of a beamway train. Road

tunnels can get an escape tunnel at practically no extra cost if the

beamway has tunnels alongside. (The heavy railway is less likely to

be nearby.) If the beamway goes in a road tunnel (behaving like a

bus), emergency preparedness can be improved by having remote

controlled beamway vehicles (with backup batteries) able to do fire

extinction, rescue/evacuation or pulling out vehicles.

Still further –

with Containers

As mentioned

above, the beamway can easily come close to other means of

transportation, but it would be best if the passengers could remain

seated in a cabin which could be transferred to another means of

transportation. On a section which already has conventional railway,

the beamway could – at least in a transition period –

cooperate with the railway. On a side track without overhead lines,

the beamway could go extra low, so that it could lower the passenger

cabin to a low well car. To hoist down passenger cabins hanging in

wires, will only be recommendable for small height differences, but

if the corners of the railway wagon has poles which can guide the

cabin, a few meters should be an acceptable vertical distance. Where

these operations take place, there will probably be cabin-handling

machinery to increase the safety and flexibility. They could for

example:

shift the cabin a

few meters sideways, so that the railway wagon can be, as usual,

under overhead lines

turn the cabin

90º, so that the beamway and railway lines can meet at a right

angle

adjust the cabin

position in cases of inaccurate driving

hold the cabin

for a while in cases of bad correspondence

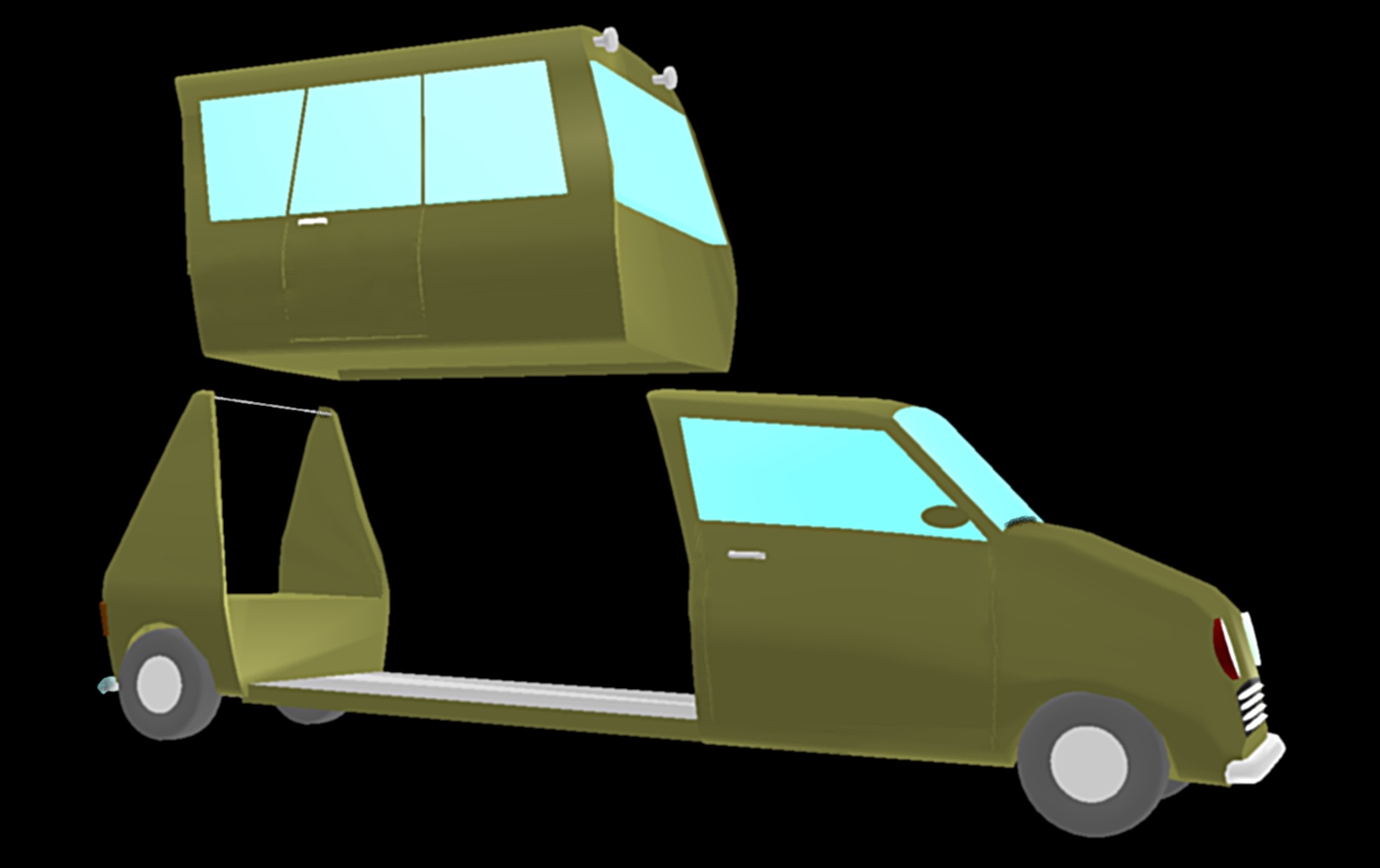

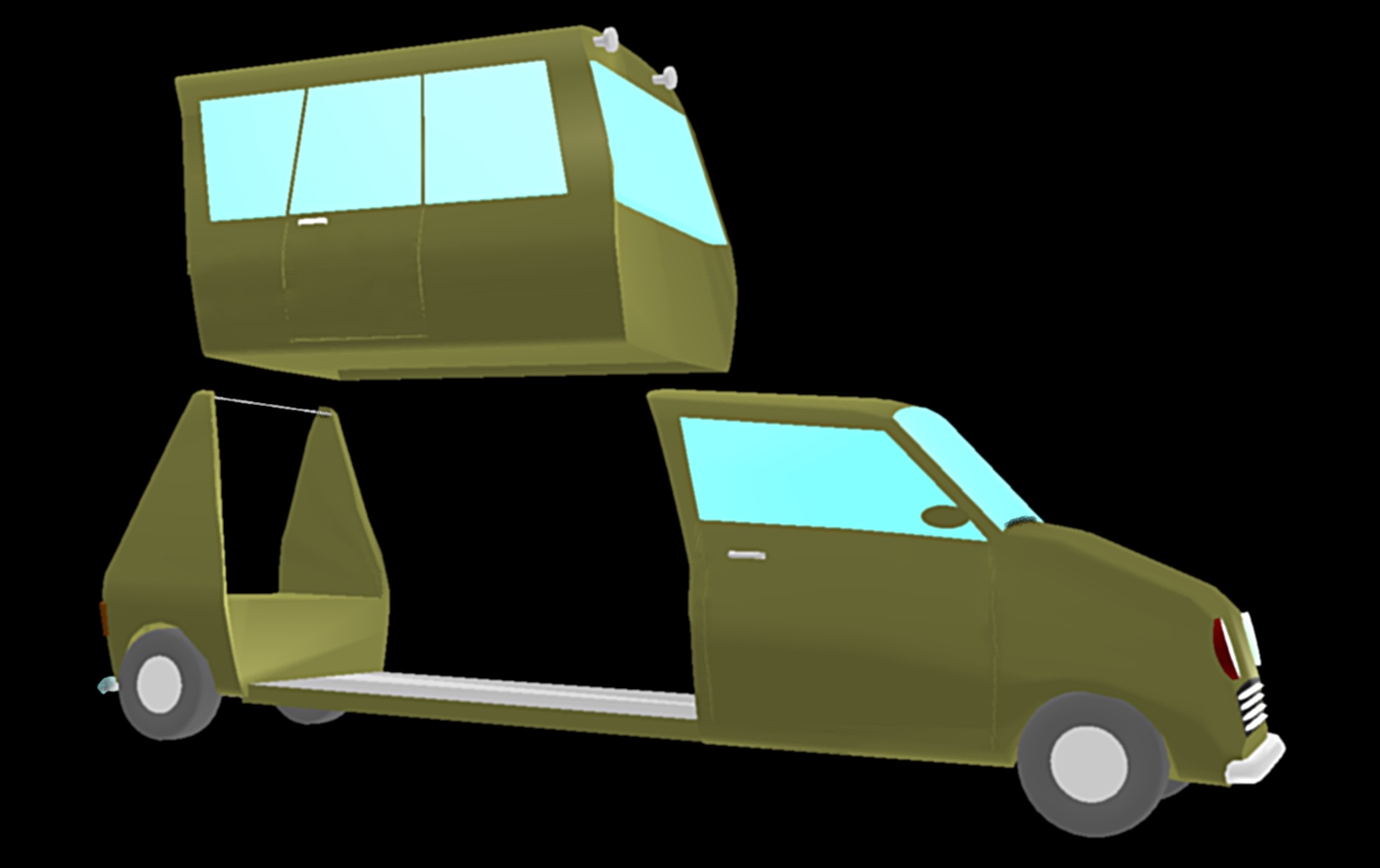

With such a

transfer station a metro train can be supplemented with buses

meandering around in the suburbs. This is an application for special

cabins with side exit and spaces for back wheels (picture below). Its

truck has, like an ordinary bus, the entrance beside the driver.

How to take

the bus.

Here we see how the beamway lowers down a frame having

teeth for grabbing by holes at the top of the sidewalls

The beamway

could in special ferry harbors approach the deck of their ferries –

special barges having space for a cabin on the deck. This could also

be fast boats for quite long distances.

We here see a cabin ready

to be lowered.

(The boat can lower its wheel house, which would

else be in the train's way.)

The cabin is

now placed on the boat, which raises its wheel house and leaves the

harbor

The bench

around the cabin is a large block of porous flotation material

The cabin can

be kept afloat if the boat goes down.

Can any boat type be safer?

Such light-weight

cabins could also be sent into the fuselage of special passenger

cabin planes. Such planes would then have double walls, and thus be

far more bomb-proof. The passenger safety could be further increased

by giving each cabin a parachute in the roof.

As the airport

train cabins go into the plane, the airport can do without a

passenger terminal. Those wishing to dispense with the entire

airport, can send the cabins into a blimp.

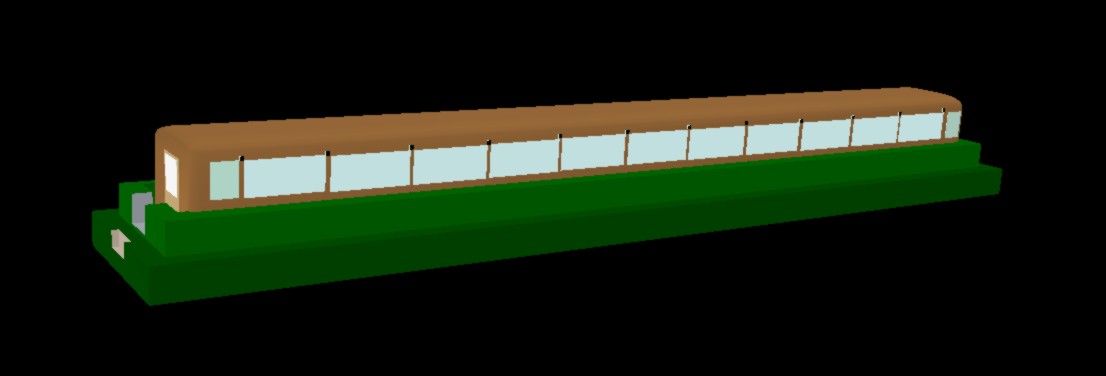

Modular Cabin

Sizes

The module sizes

for the cabins should start with a maximal length corresponding to a

railway wagon – the brown one in the pictures. A suitable

length for this could be 24 meters, so that it could run like an

ordinary railway wagon if placed on a well car. The other lengths

should be fractions like 12, 8, 6 and 4 meters. The yellow “bus”

in the pictures is 8 meters long. The private cabins in the two last

pictures are also 8 meters long, but could have other lengths. A 6

meter car carrier could be useful for moving cars to and from places

lacking road connections – mainly islands within jumping

distance of the beamway.

A frame for

grabbing a 24-cabin could take a shorter passenger cabin (near the

center wagon) + one or more compatible mail containers. The frame for

grabbing the bus cabin could take two 4-meters mail

containers.

Grand

stand cabins – 24 meters long.

They could be placed

on the ground before use, or run with the spectators seated.

Also small

boats/houseboats could be produced in module format and with

compatible grabbable holes, e.g. in the rail as shown in the picture

below. Everything else can then be shaped as a real boat, so the

difficult combination design of amphibian crafts is avoided. Wherever

a beamway takes a shortcut over water, such a boat can be lowered or

hoisted. It may become practical for inland people to do this for

every boat trip. And large boat-houses for beamway-launchable boats

may become popular.

A boat with a

rail which can be grabbed by a standard frame.

Ordinary boats

could be transported short distances held by loops under the hull.

Cargo

As long as the

weight load on each beam length (30-40 m) doesn't exceed the load of

passenger transport – 2-300 kg for each meter train length –

the beamway can of course be used for cargo transport. This load can

be reduced by using cargo wagons with a smaller cross-section area,

and have several meters between wagons. The cargo train may then

become quite long, but due to the higher acceleration of this light

train, it can avoid getting in the way of other trains. The reduced

transport efficiency caused by having intermixed trains with strongly

varying weight and speed is avoided.

The limited cargo

weight is largely compensated by the adaptability of this rail

system. This is also related to the possibilities for automatic

(unmanned) driving above the ground scene, and the fact that the

track can go over factory fences and into manufacturing halls.

The beamway can

take care of the fuel transport of the future by transporting

hydrogen tanks. These need not be compact, having high pressures. A

few hundred atms will be fine.

Cargo

containers hang on the sides of this special freight train, and can

be put down on a shopowner's pickup – no station needed.

One

or more containers can be replaced by a motor pack – no

locomotive needed.

These wagons with vertical chassis are optimal

for controlling and distributing the load along the beam.

This

beamway is reinforced with (carbon fiber) wires.

Additional Passenger Wagons

A passenger train may be extended with

additional passenger wagons at the front

and/or rear. The passengers in these must go through the regular

wagons, so normally additional trains would be

used instead. Extra carriages may, however, be

appropriate if they provide extra facilities

for existing passengers, and not used for increasing

the number of passengers - at least not with a normal passenger

density.

Such

supplementary wagons can provide:

These

are not needed for short trips, so the

walk through the regular

passenger wagon will not be too annoying. As

the passenger densities

in these extra wagons are

small, the train will not become too heavy. This is because the extra

wagons to a small extent increase the weight load on the same beam,

but rather on the neighboring beam and the

pole between them.

Private Pods

It

is popular to propose new transport systems based upon privatized

small wagons – often called pods – and often as

automatized taxis running on rails or under beams. These proposals

imply establishing a new transport infrastructure directed at the

transport needs of quite small regions, and they tend to disregard

the handicapped, groups needing more than one pod, as well as the

need for using toilets during the trip.

The

variant to be proposed here follows our principle with a passenger

cabin being detachable from the bogie under which it hangs. (A bogie

is a little motorized 4-wheeled "wagon" running inside the

beam.) These small cabins are so simple and versatile that they are

likely to often be privately owned. They can, as depicted below, be

carried inside carrier wagons in high-speed trains for long trips, or

upon rented or owned cars/boats.

When

the cabins are held in the carrier wagon of a fast train, the

passengers can walk through a corridor to and from their cabins, the

cabins of companion travelers, the toilet and perhaps a (food) store.

They needn't complete the trip as a pod traveler or a train

passenger, but can change status on the train, using the train's

elevator only at the start or the end of the trip. Or they can join

the group in another wagon.

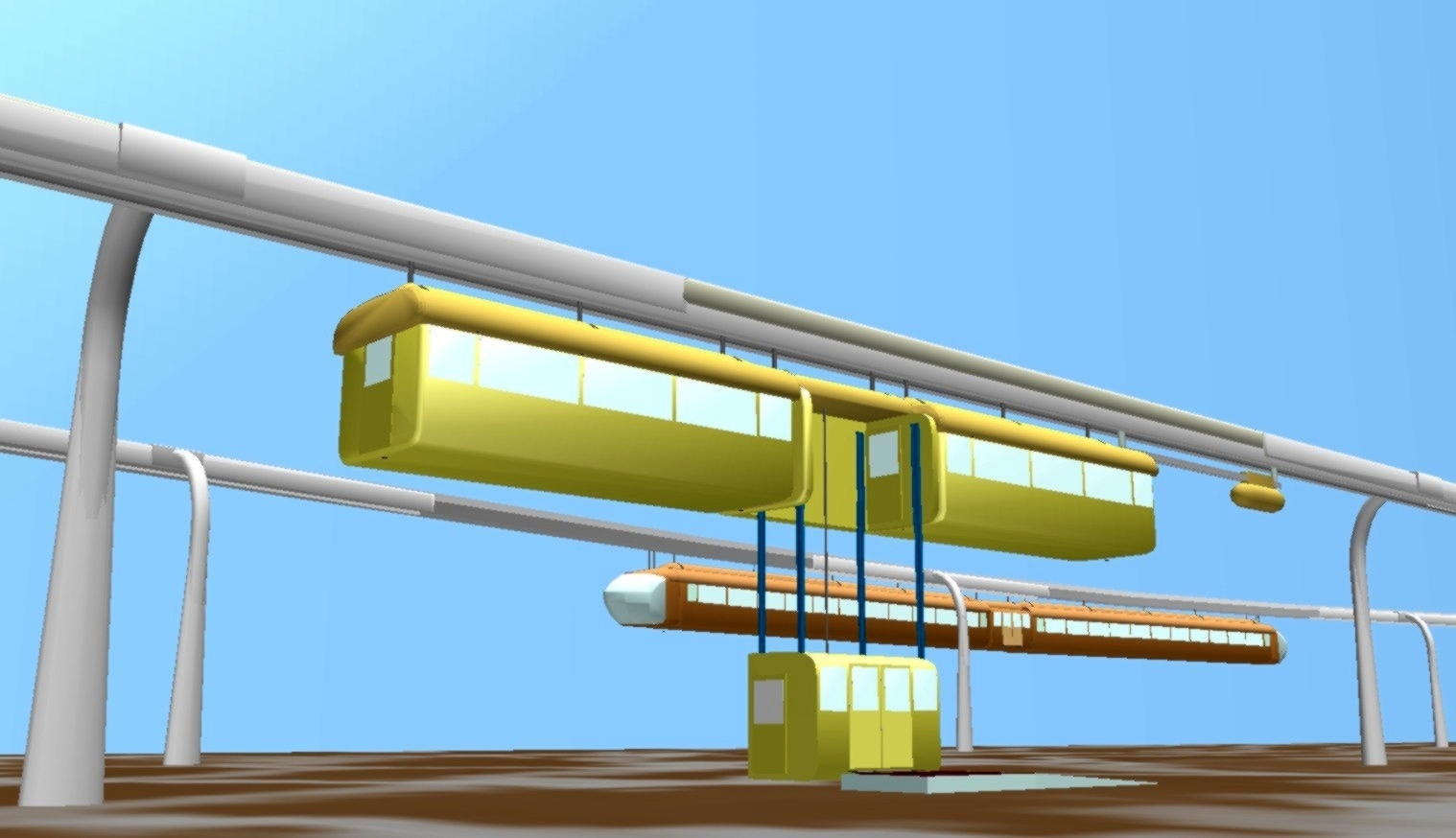

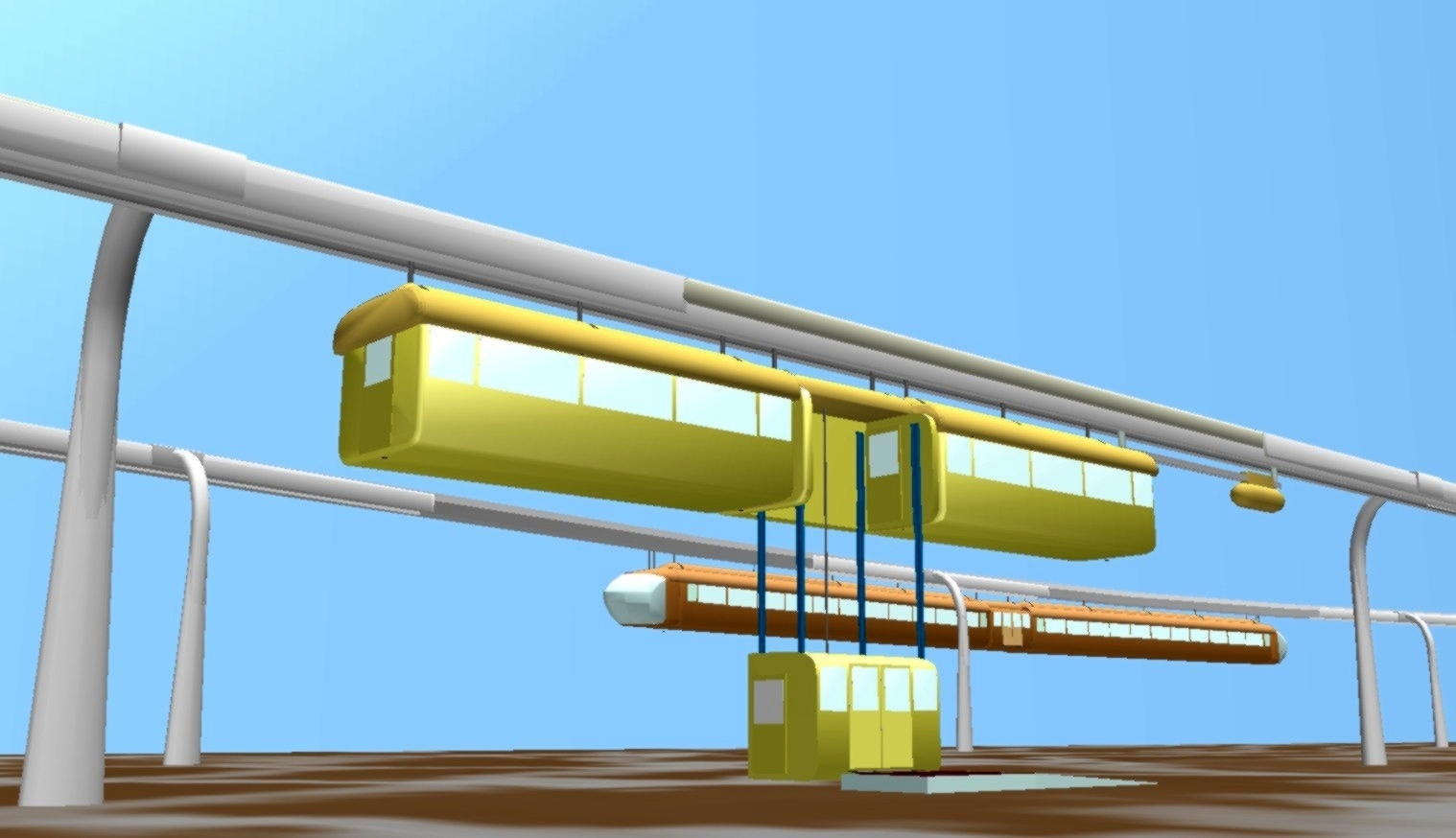

Small

cabins (under the nearest beam) are here transferred to and from the

rear wagon of a train (hanging under the mostly concealed beam). This

pod carrier wagon can carry 8 pod wagons. The blue wagon has moved

sideways all the way into the carrier, the brown one half-ways in,

while the yellow one is still in normal position under the beam. The

(upper and lower) doors are still closed for the 5 remaining

compartments.

The

cabins have small, motorized wheels fore and aft on the top, so that

they can move sideways along the transverse mini-beams they are

suspended under. From these mini-beams (hanging under the front and

back of a bogie), a cabin can move onto abutting mini-beams hanging

under the ceiling of a carrier wagon or a parking facility. Cabins

can be stacked in multistory parking facilities, as they (and frames

with the mini-beams) can be hoisted and lowered by wire (up to 6

meters). This movement can be used for emergency escape in normal

terrain.

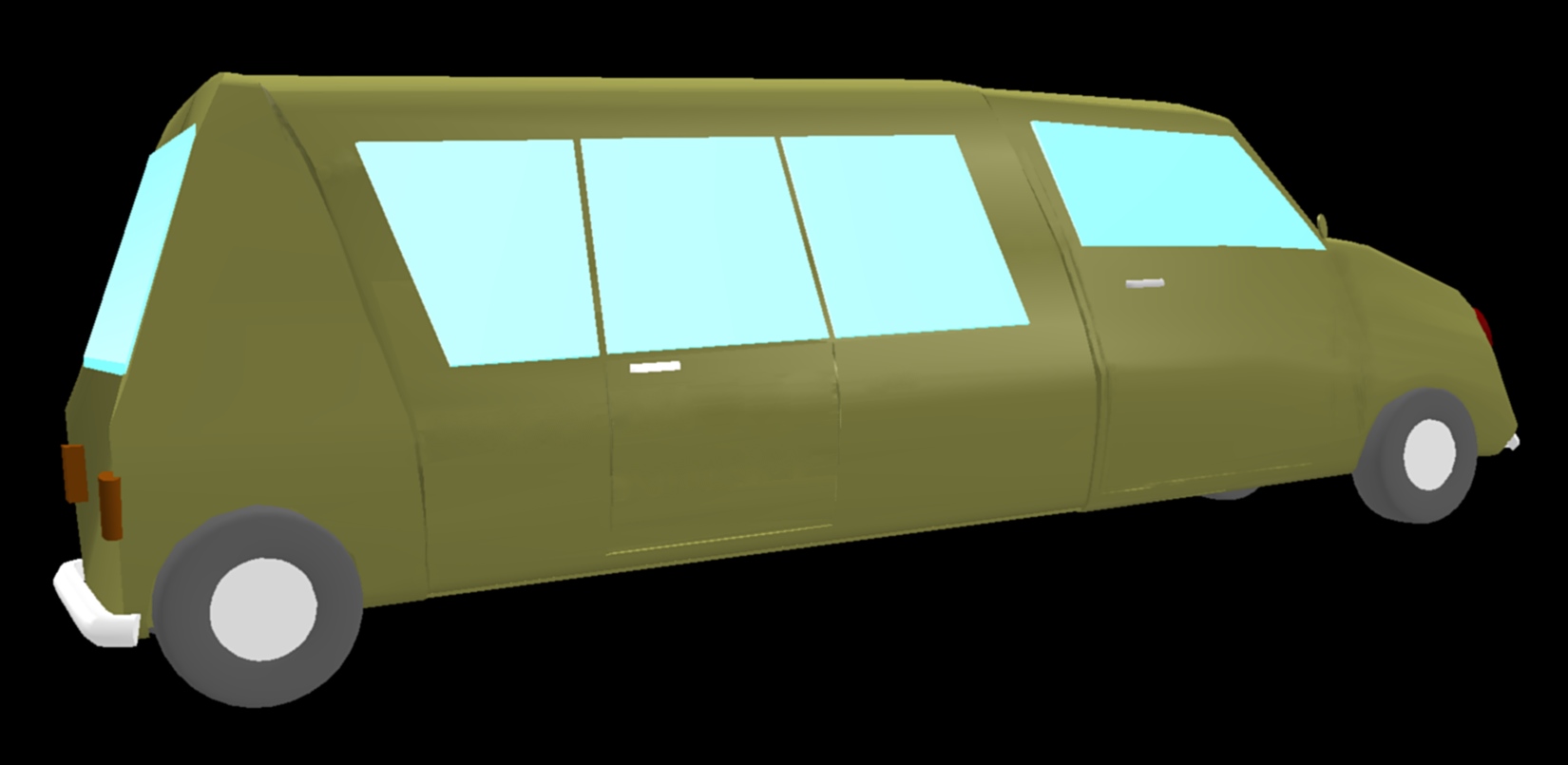

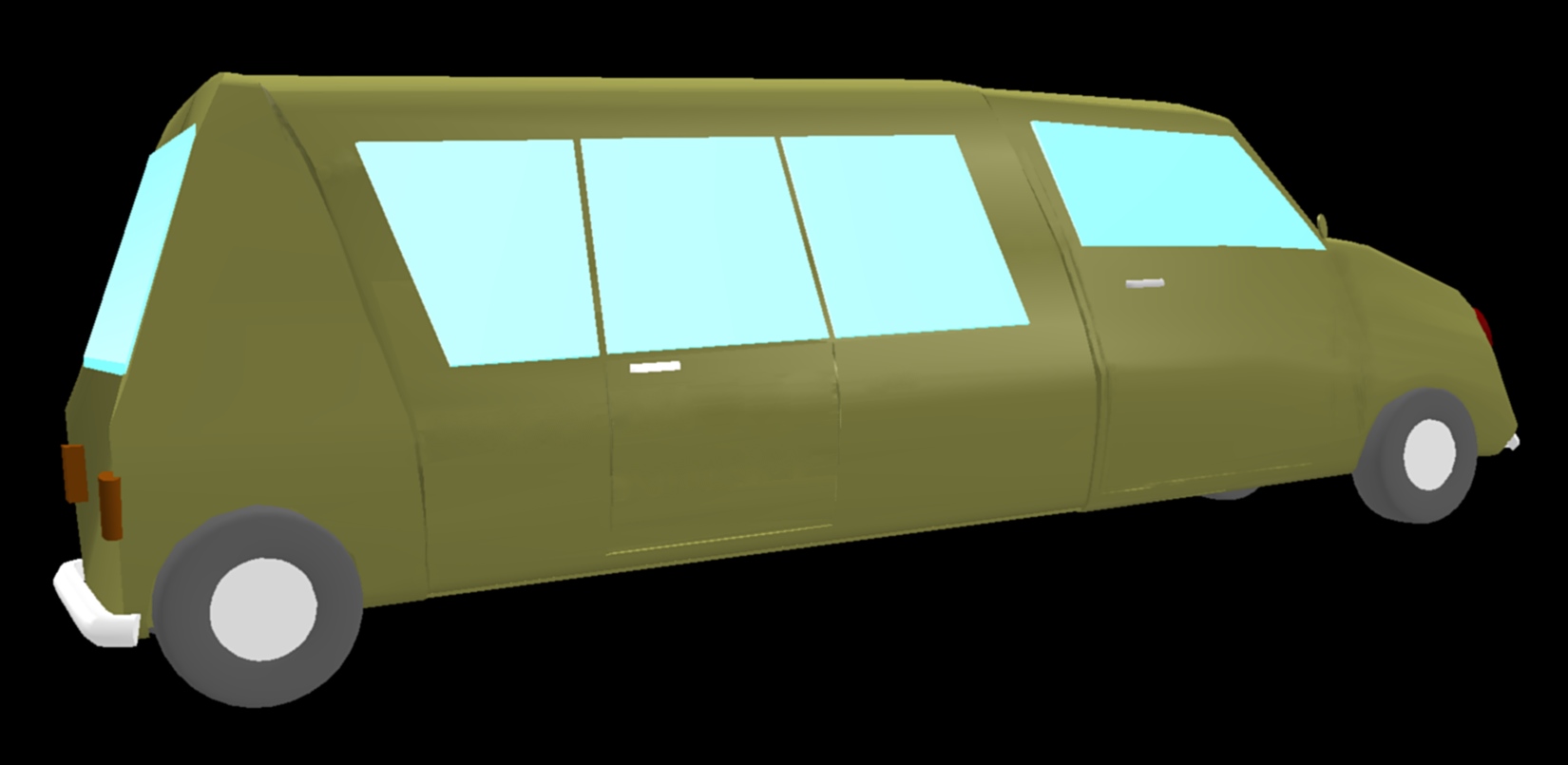

This

shows how a 2.5x1.5 meter cabin can be positioned upon a small car

(red outline) or a catamaran boat (blue outline).

Without an

external driver compartment (which the limo-sized vehicle above has)

the most space-saving seat arrangement, with two reversed seats along

the front wall, may not be used.

This car (like the previous

limo-sized one) gets a rear baggage trunk when the top-hinged back

door is swung somewhat back.

It

may be concluded that either of two seat configurations are likely to

be chosen for a cabin, depending on if an internal driver's seat is

needed.

Cabins

with not more then a few folding seats may be used by wheelchairs.

For privately owned cabins, many layouts may be used, with foldaway

berths, baby seats, storage furniture, etc.

Cabins

can also have wheels, motor and batteries, so that they become

complete cars. But these will become two-seaters with small wheels

and inferior driving characteristics – mainly for local

driving.

Transport of Cars

Beamway trains for

cars may be useful for various purposes. They can carry cars to

places where a road connection will be too expensive and/or bad for

the environment – e.g. to sparsely populated islands. Or they

can carry cars through a submerged tunnel, where centralized

operation is important, and where combustion engines cannot be used.

But even if there is a good road connection, a car-carrying beamway

will be a good idea – because:

The train can go

2-3 times faster than cars, and with far greater safety.

The driver can

spend the time doing something useful – like resting.

Toilets will be

available during the trip.

CO2

emissions are greatly reduced.

Electric cars get

a very different operating range – especially if they can be

recharged during the trip. The car batteries may then be used by the

train as backup batteries.

A wagon for cars

will have approximately the same shape and appearance as a passenger

wagon, but can be made extra long and rigid, so as to not weight down

the weak central part of the beam. The wagon's ends – made

round and aerodynamic by containing toilets – can slide/swing

aside, permitting cars to pass through. The cars are not obstructed

by the next wagon, as the gap between wagons can be several meters

wide, and a wagon can be rotated sideways by displacing the ends

perhaps a meter to different sides.

At the stations,

the beam should be so low that the wagons are just above the ground,

and then one or both wagon ends can be lowered to the ground. This

can be done by means of wires which are so long that wagons in an

emergency can be lowered from normal beam height. The station may be

a ferry deck, a bridge or a building.

Trains carrying

cars will not be particularly heavy. A load weight of 300-350

kg/meter should be about the same as an ordinary passenger wagon

should be designed for. Actually, a passenger wagon must be designed

for far greater local loads, as its contents may lump together in one

end of the wagon.

Mobile

Services

The automatic

driving enables services which have previously been impossible, or at

least uneconomical. A traditional bookmobile, for instance, is about

12 meters long and needs both a librarian and a bus driver. It can be

replaced by a beamway wagon which might be 24 meters long and can do

without a driver. A simple little sidetrack beam is needed for each

stop to be used by this "book tram" and similar services.

As passengers are not transported, the cabin can simply be lowered to

the ground by wires. It can still have power connection there.

At the day's end,

the wagon is hoisted up, and is then quite well secured. It might

also run to a similar sidetrack near the librarian's home.

The same principle

can be used for e.g. various medical services: mobile dentist,

polyclinic, blood bank...

The strongly

reduced expenses for wages and fuel could lead to a closedown threat

being turned into expansion plans.

Such a service

might become rather one-dimensional, but if it had been more

two-dimensional, a structure coarseness could still necessitate

supplementary short distance transport like car, bike, taxi, local

bus... It might actually be easier to obtain an efficient local

transport system if short trips to a beamway stop are known to be

needed frequently.

If the mobile

services are needed at many locations, downhoistable cabins (like the

yellow bus cabin depicted above) for use on special trucks may be

used. Then a local driver can be engaged for just two small

assignments: Move the cabin from the beamway to the point of service

in the morning, and then move it back again in the afternoon. Very

long cabins (perhaps 24 meters) can be used on roads when it is known

on which stretches they are to be employed. Long cabins are easier to

handle on the road if they and their trailers are articulated like an

articulated bus.

Kindergartens can

have their own trains running around in residential areas picking up

the kids in the morning, and going out to deliver them in the

afternoon. If parents are too late with their delivery in the

morning, they deliver to a local short-term kindergarten instead. And

if parents are not showing up in the afternoon, they do the pick-up

at that place – which may be a wagon able to move as called

upon. Anyway, parents should be able to manage without cars.

The main

kindergarten can be a large, central facility quite far away, and the

wagon can be the child group's own room here. It will also be simple

to go driverless on excursion to various places.

Also schools can

obtain such an economy of scale when students easily can be

transported quite long distances, but these students can use the

normal trains. Alternatively to obtaining economy of scale, the

school system can make special educational varieties available for a

large area.

Running

(between) Hospitals

Hospitals will be

the first candidates for using a public beamway network for their

"private" purposes. That is: They should be able to

dispatch their own (mostly small) wagons to and from their own

beamway stations in hospitals. Transport of patients, medical staff

and parcels (with medicines, equipment...) between hospitals can be

automated like the pneumatic tube systems used in hospitals.

Ambulance vehicles – and even wagons from normal trains that

happens to become involved – can run directly into the

emergency room.

This will be

possible because long distance lines (for e.g. 200 km/h) and local

lines will use compatible and interconnected beamways, with computer

controlled operation. This automatization is easy because the beamway

vehicles are alone in their elevated level. The local lines will of

cause get a stop within a short walk from each hospital. The only

line connection costs falling upon a hospital will then be for

building a beamway beam (normally 100-200 meters long) going into a

hospital building.

Being able to run

between hospitals in this manner will enable running hospitals more

efficiently and economically.

Post

The beamway is

able to dispatch more or less private wagons automatically, and this

ability could be used for at least delivering parcels. The central

element will then be an automat for storing and delivering parcels of

various sizes – like a vending machine. The wagon – a

robotic postman – will need such a mechanism for organizing the

parcels it distributes. The mechanism needn't be burglar proof, as

transferring parcels to the delivery automat is automatic. Each

parcel might be stored in a cloth bag, as these easily can hang or

lie together in a space saving manner. When the post wagon arrives at

the delivery place, it transfers the parcel to another automat. This

is – like a vending machine – accessible to the general

public, so it must be rather burglarproof. It might have a shelf,

perhaps rotating, with movable dividing walls ensuring efficient

space utilization. The recipient opens the correct partition with a

key or access code. Two shelf sizes may be needed, having different

cross-section areas, for accomodating a wide range of parcel formats

economically. But some parcels will be too large for a neighborhood

facility, so the recipient must take the train to a post office –

which might have a staff.

Alternatively,

parcels can simply be placed in the open on the delivery site. The

recipient will then acknowledge an arrival message by phone, and

later signal he is ready to pick up the parcel on the site.

To send a parcel

is somewhat more complicated. The automats could be made reversible,

but the system must have the destination address machine-readable. It

could be entered with an app on a cellular phone (which can check the

address in an address database), or a USB stick with the address in a

certain file could be plugged into the automat.

If this system

becomes cheap and simple, it might also become used for goods to be

recycled.

A new Tourism- or

Home Type

When passenger

transport in standard cabins starts becoming common, people will buy

their own camping cabins and perhaps compatible small boats. Special

cruise ships for these will actually be container ships which have

platforms for private module cabins instead of normal fixed ship

cabins. When the passengers arrive at an interesting destination, a

beamway beam will be pushed in over the ship and lift up the cabins

of the passengers who want to get ashore there. They will then be

transported to the campsite (or small boat harbor) of their choice.